Automatic face changing device

An automatic and conveyor belt technology, applied in the field of automatic face changing devices, can solve problems such as difficulty in adapting to modern mass production, potential safety hazards, and slow process rhythm, and achieve stable and reliable turning process, full automatic control, and labor saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

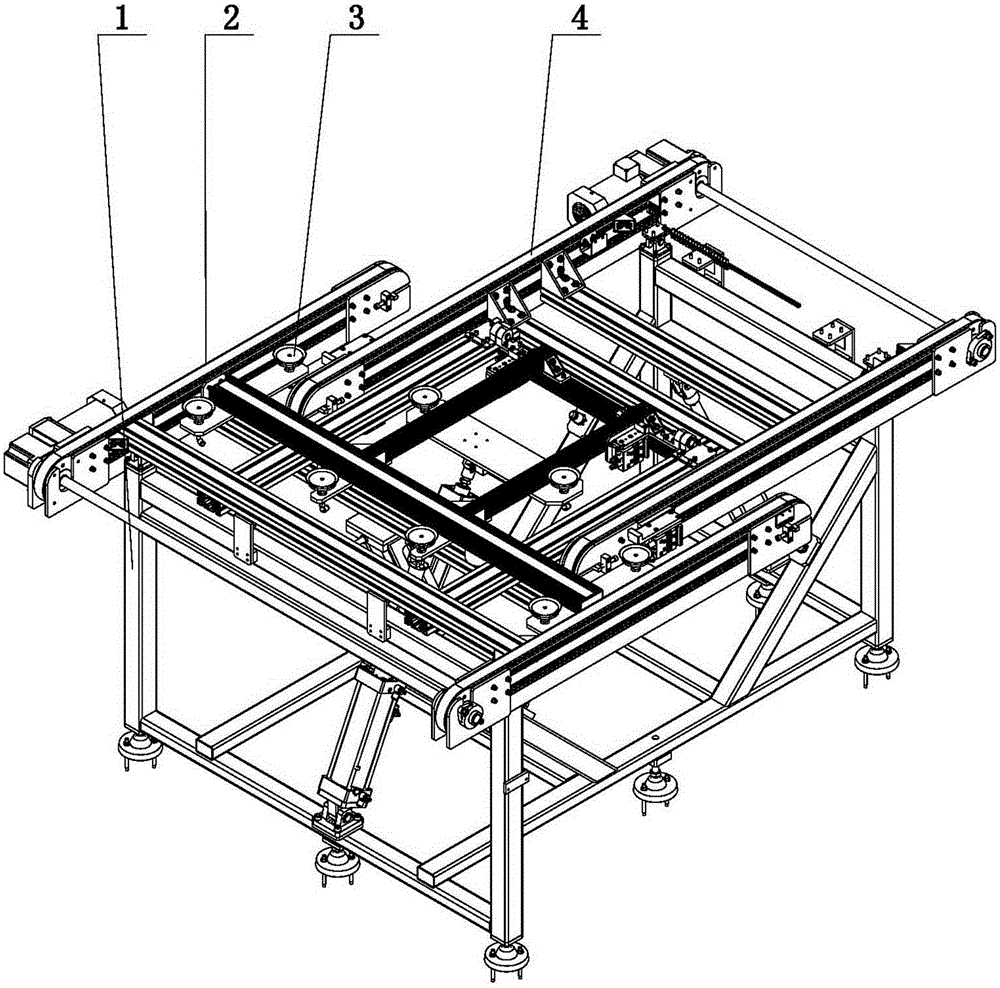

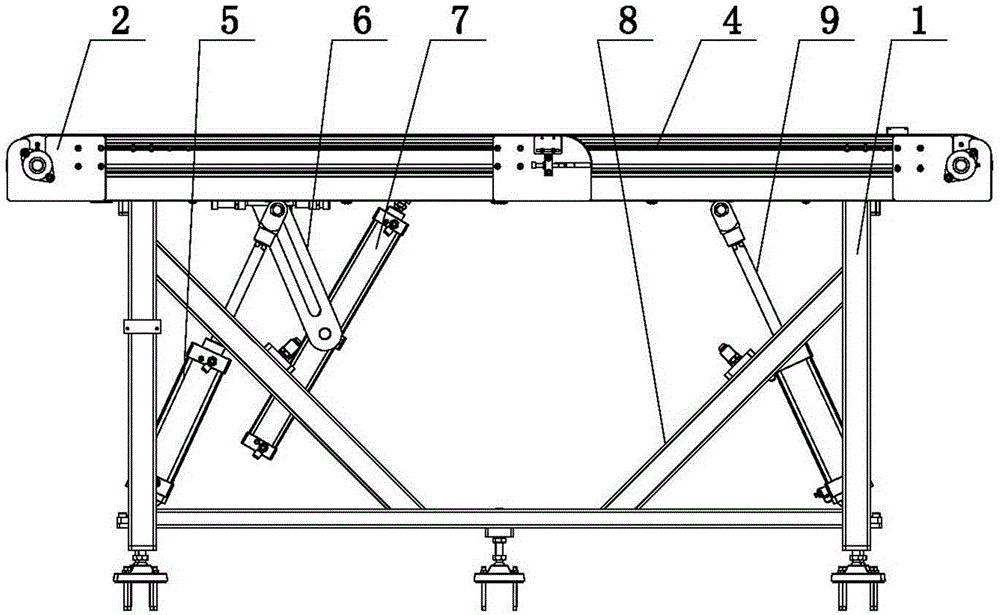

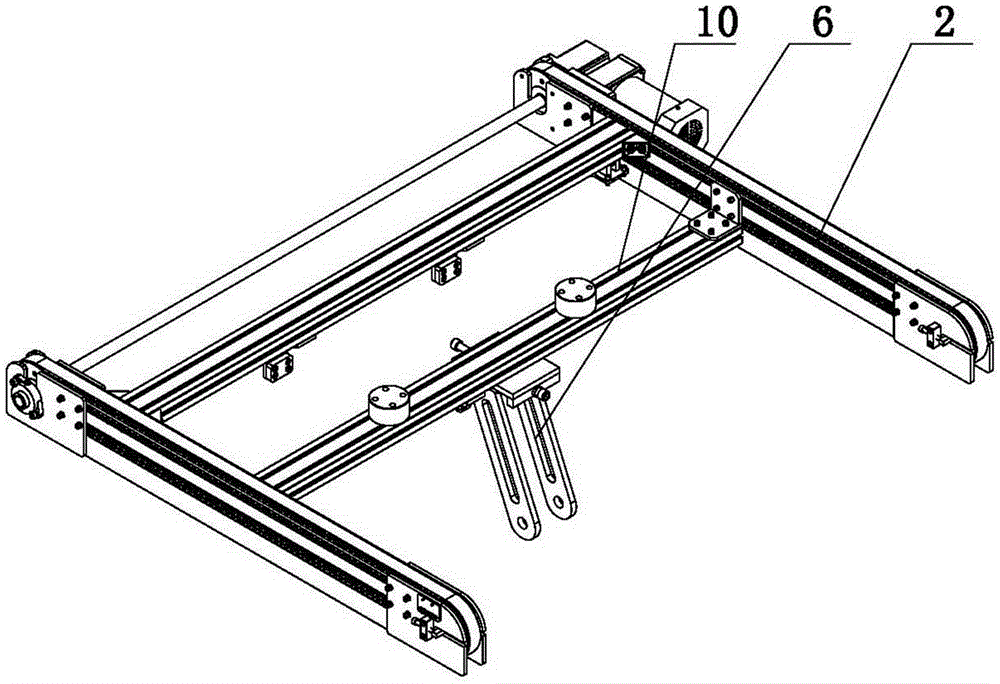

[0018] The present invention includes a frame 1, which is characterized in that: the two ends of the frame 1 are respectively hingedly provided with a first conveyor belt 2 and a second conveyor belt 4, and a first tilting cylinder is arranged between the first conveyor belt 2 and the frame 1 5. A second inclined cylinder 9 is provided between the second conveyor belt 4 and the frame 1; a connecting frame 6 is provided below the first conveyor belt 2, and a turning cylinder 7 is hinged on the connecting frame 6, and the turning cylinder 7 is A suction cup device 3 is provided, and the suction cup device 3 is hinged to the frame body 10 of the first conveyor belt 2 .

[0019] As a preferred solution of the present invention, the frame 1 is provided with inclined support frames 8 corresponding to the first conveyor belt and the second conveyor belt.

[0020] As another preferred solution of the present invention, the end of the first conveyor belt 2 is provided with a touch posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com