Blanking baffles for loading and unloading raw materials on docks

A wharf and baffle technology, applied in the field of wharf logistics, can solve the problems of material loss and marine environmental pollution, and achieve the effects of reducing material loss, convenient operation, and preventing marine environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is further illustrated below by specific examples.

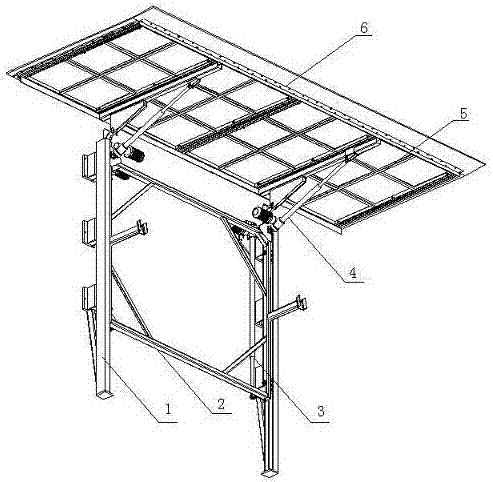

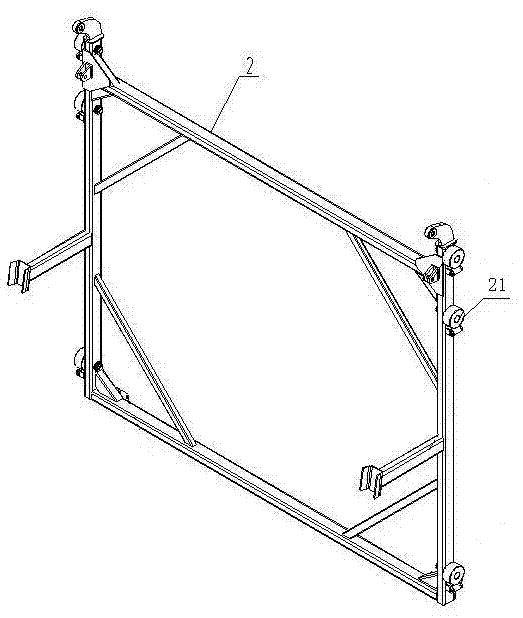

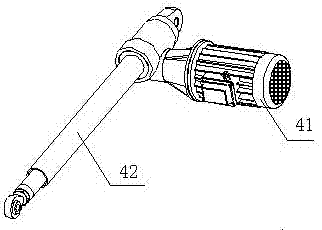

[0024] like figure 1 , as shown, a blanking baffle for loading and unloading raw materials at the wharf, which includes a fixed frame 1, a movable frame 2, a lifting device 3, a turning drive device 4, a baffle frame 5 and a baffle 6; Frame 1 is fixed on the side of the wharf bank; as figure 2 As shown, the movable frame 2 is a planar frame, which is arranged in the fixed frame 1; the lifting device 3 is vertically arranged on one side of the fixed frame 1, and one end thereof is connected with the fixed frame 1, and the other end is connected with the movable frame 2, The movable frame 2 is driven by the lifting device 3 to slide up and down along the fixed frame 1; the top of the movable frame 2 is symmetrically provided with an overturning drive device 4 on both sides, and the top of the baffle frame 5 rotates with the top of the movable frame 2 connection, the overturn drive device 4 is sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com