Ethylene-vinyl acetate copolymer based thermoplastic semiconductive shielding material for conductor and preparation method of thermoplastic semiconductive shielding material

A vinyl acetate copolymer, vinyl acetate copolymerization technology, applied in the field of thermoplastic semi-conductive shielding materials for conductors and its preparation, can solve the problems of mismatching extrusion temperature and extrusion performance, inability to extrude, pre-crosslinking of shielding materials, etc. , to prolong the storage time, solve the problem of easy water absorption and increase the processing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

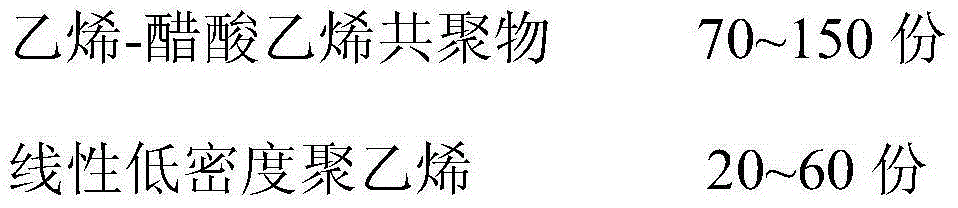

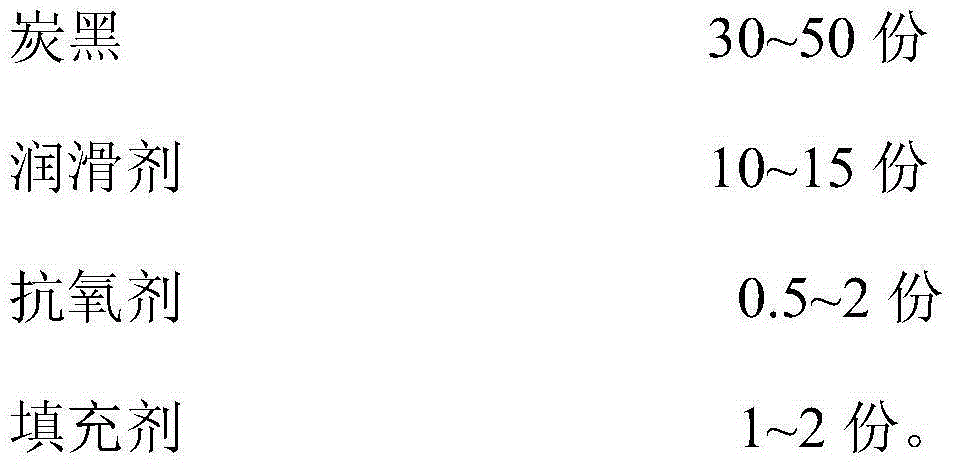

[0027] The thermoplastic semi-conductive shielding compound for conductors based on ethylene-vinyl acetate copolymer consists of the following components in parts by weight: 70 parts of ethylene-vinyl acetate copolymer, 20 parts of linear low-density polyethylene, 30 parts of carbon black, and 10 parts of lubricant , 0.5 parts of antioxidant and 1 part of filler; the lubricant is made up of the following components by weight: 5 parts of white oil and 1 part of polyethylene wax; the white oil consists of No. 100 white oil and No. 200 white oil according to the weight ratio It is formulated at a ratio of 1:1; the molecular weight of polyethylene wax is 4000-5000; the antioxidant is antioxidant 1010; the filler is nano-calcium carbonate.

[0028] The preparation method of the above-mentioned thermoplastic semiconductive shielding material for conductors based on ethylene-vinyl acetate copolymer is:

[0029] According to the above formula ratio, add ethylene-vinyl acetate copolyme...

Embodiment 2

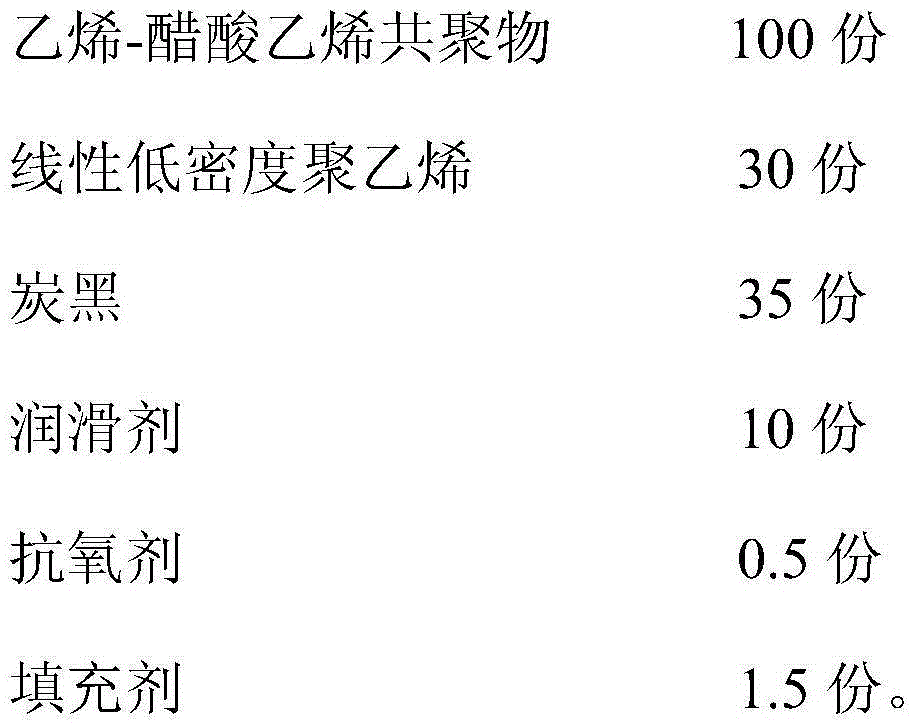

[0033] The thermoplastic semi-conductive shielding material for conductors based on ethylene-vinyl acetate copolymer consists of the following components in parts by weight: 100 parts of ethylene-vinyl acetate copolymer, 30 parts of linear low-density polyethylene, 35 parts of carbon black, and 10 parts of lubricant , 0.5 parts of antioxidant and 1.5 parts of filler; lubricant is made up of the following components by weight: 8 parts of white oil and 2 parts of polyethylene wax; White oil is by weight ratio of No. 100 white oil and No. 200 white oil It is formulated at a ratio of 1:1; the molecular weight of polyethylene wax is 4000-5000; the antioxidant is 1010; the filler is nano-calcium carbonate.

[0034] The preparation method of the above-mentioned thermoplastic semiconductive shielding material for conductors based on ethylene-vinyl acetate copolymer is:

[0035] Add ethylene-vinyl acetate copolymer, linear low-density polyethylene, carbon black, lubricants, antioxidant...

Embodiment 3

[0039] The thermoplastic semi-conductive shielding compound for conductors based on ethylene-vinyl acetate copolymer consists of the following components in parts by weight: 150 parts of ethylene-vinyl acetate copolymer, 60 parts of linear low-density polyethylene, 50 parts of carbon black, and 15 parts of lubricant , 2 parts of antioxidants and 2 parts of fillers; the lubricant consists of the following components by weight: 10 parts of white oil and 3 parts of polyethylene wax; the white oil consists of No. 100 white oil and No. 200 white oil according to the weight ratio It is formulated at a ratio of 1:1; the molecular weight of polyethylene wax is 4000-5000; the antioxidant is antioxidant 1010; the filler is nano-calcium carbonate.

[0040] The preparation method of the above-mentioned thermoplastic semiconductive shielding material for conductors based on ethylene-vinyl acetate copolymer is:

[0041] Add ethylene-vinyl acetate copolymer, linear low-density polyethylene, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com