Quenching device of supporting wheel

A technology of quenching device and roller, applied in the direction of quenching device, heat treatment equipment, furnace, etc., can solve the problem of different hardness, achieve uniform hardness, improve hardness and quenching efficiency, and prevent deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

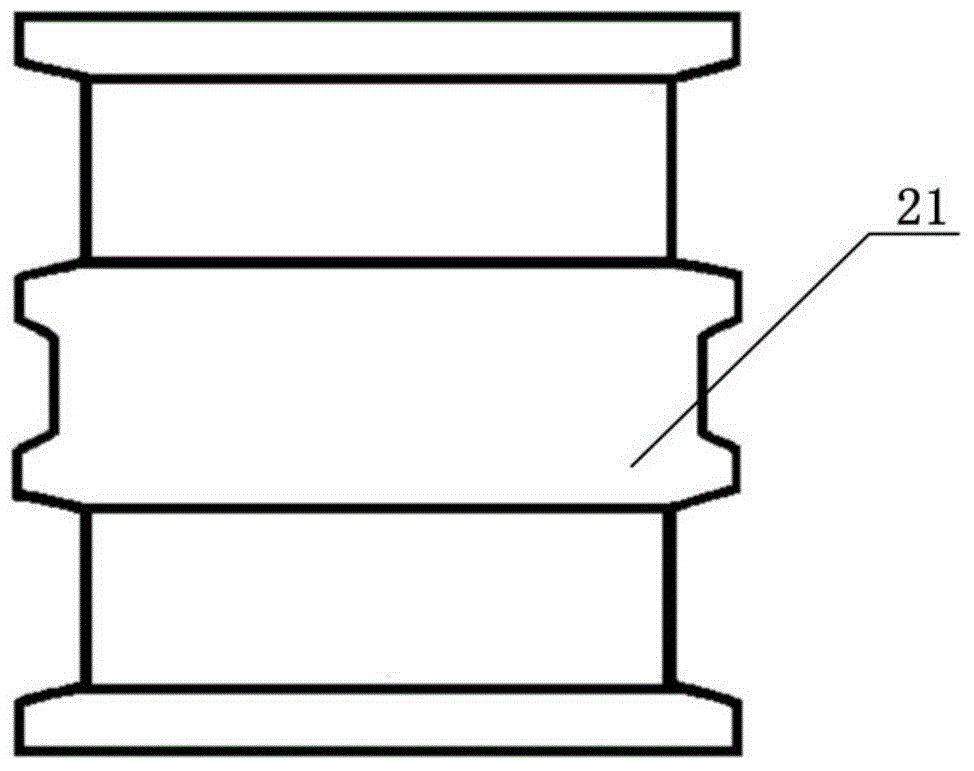

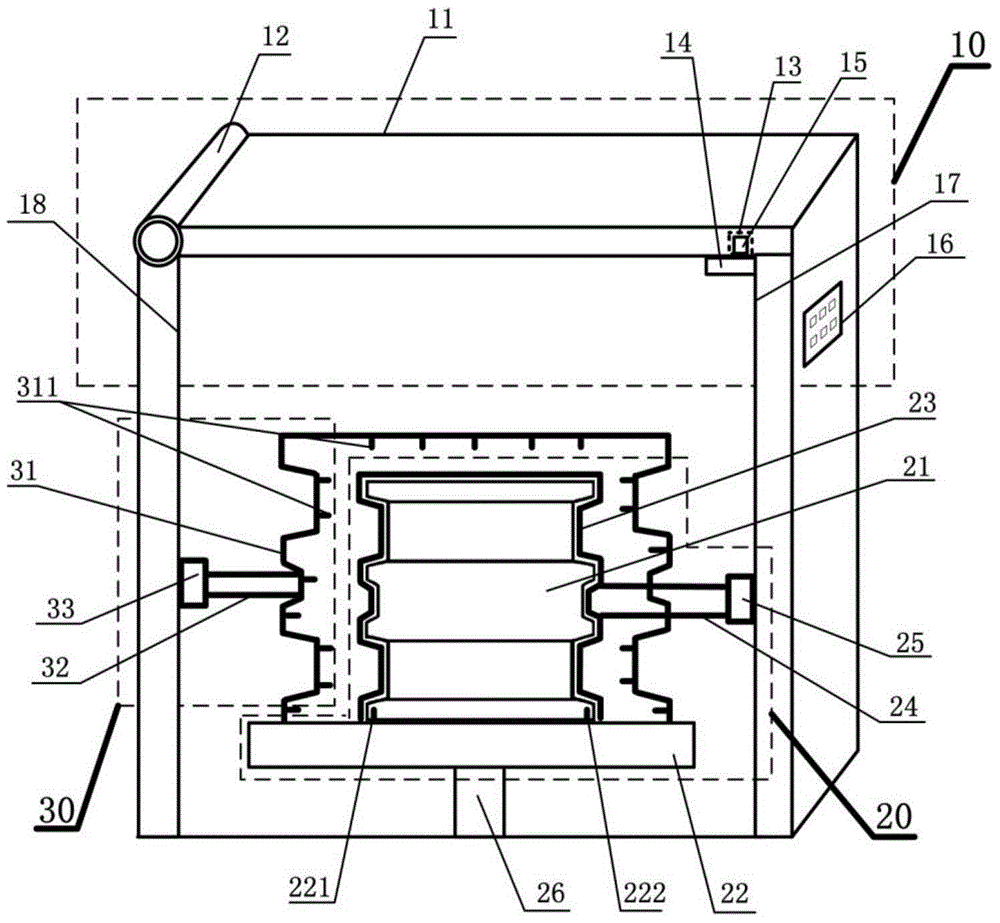

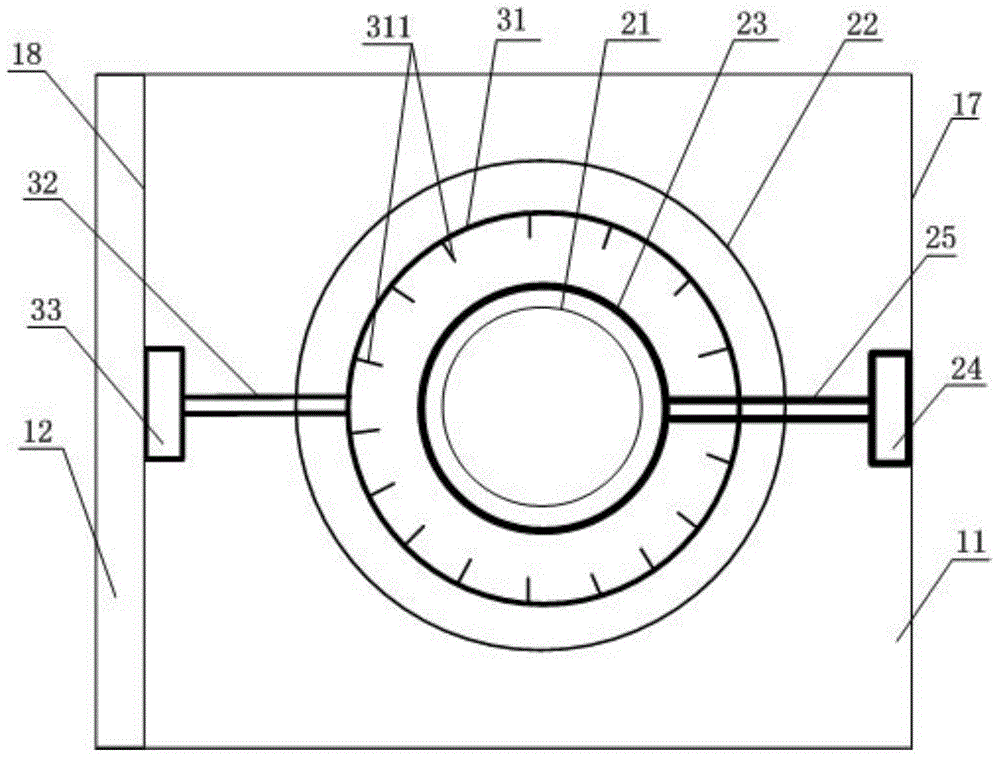

[0033] figure 1 It is a structural schematic diagram of the supporting wheel of the present invention, figure 2 and image 3 An implementation form of Embodiment 1 of the present invention is shown.

[0034] Depend on figure 2 and image 3 It can be seen that the quenching device for the rollers of the present invention includes: a frame body 10 for providing a sealed and heat-insulated environment; a heating unit 20 for inductively heating the rollers 21; the heating unit 20 includes a The platform 22 carrying the supporting wheel 21, the induction coil body 23 for heating the supporting wheel 21 and the supporting shaft 26 for rotation: the platform 22 is located above the supporting shaft 26 and rotates under the drive of the supporting shaft 26; the induction coil The body 23 is a hollow column with the same shape as the supporting wheel 21. The size of the induction coil body 23 is just sleeved on the outer side of the supporting wheel 21; the induction coil body 23...

Embodiment 2

[0043] On the basis of Example 1, Example 2 is a quenching method using the quenching device for the roller provided in Example 1. Figure 4 It is a flow chart of the method for quenching a roller in the present invention, showing an implementation form of Embodiment 2 of the present invention. Depend on Figure 4 It can be seen that the quenching method steps of the roller 21 are as follows:

[0044] S1: place and position the supporting wheel 21 on the platform 22: rotate the rotating shaft 12, the groove 13 is separated from the protrusion 15, the cover plate 11 is opened, and the manipulator places the supporting wheel 21 on the platform 22 to the first limit block 221 and The second limit block 222 is just covered by the bottom inner ring of the supporting wheel 21; the rotating shaft 12 is rotated, the groove 13 is engaged with the protrusion 15, and the cover plate 11 is closed;

[0045] S2: Carry out high-frequency induction heating and medium-frequency induction hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com