A wool top rewashing method, wool oil filling system and wool top rewashing machine

A filling system and synthetic wool oil technology, applied in the field of fabric weaving, can solve the problems of reduced service life of press rollers, increased power consumption, waste of synthetic wool oil and steam, etc., and achieve the effect of improving efficiency and reducing yarn breakage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

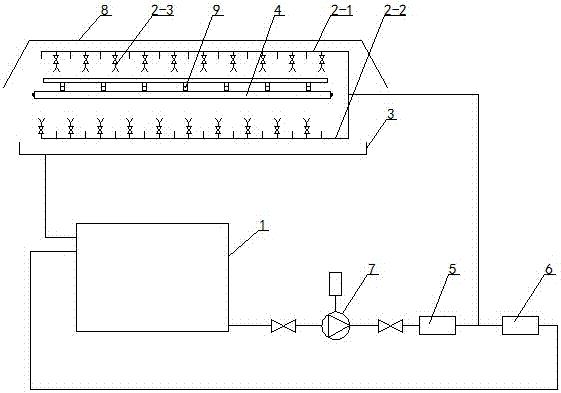

[0065] as attached figure 1 As shown, the wool oil filling system of the present invention is mainly composed of a filling box 1, a spray mechanism, an oil return tank 3, a top running mechanism 4 and a humidity measuring element 9.

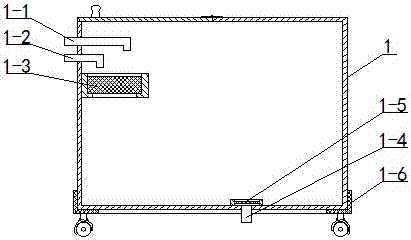

[0066] as attached figure 2 As shown, the filling tank 1 is a stainless steel volume barrel, which is used for mixing materials and storing mixed wool oil. An oil return pipe joint 1-1 and an oil overflow pipe joint 1-2 are fixed on the side wall of the filling tank 1 top. A feed filter assembly 1-3 is fixed below the oil return pipe joint 1-1 and the oil overflow pipe joint 1-2 in the filling tank 1 . A discharge filter assembly 1-5 is installed at the discharge port 1-4 at the bottom of the filling tank 1 . For the convenience of transfer, the filling box 1 can be arranged on the transfer bracket 1-6 with pulleys.

[0067] The discharge ports 1-4 of the filling tank 1 are connected to the spraying mechanism through a pipeline and a high-pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com