Ultra-short-radius radial lateral drilling method for horizontal wells

A sidetracking horizontal well, ultra-short radius technology, applied in directional drilling, earthwork drilling, wellbore/well components, etc., can solve the problems of short drilling time, low construction cost, poor safety, etc., and reduce downhole complex situations , low drilling cost and good promotional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

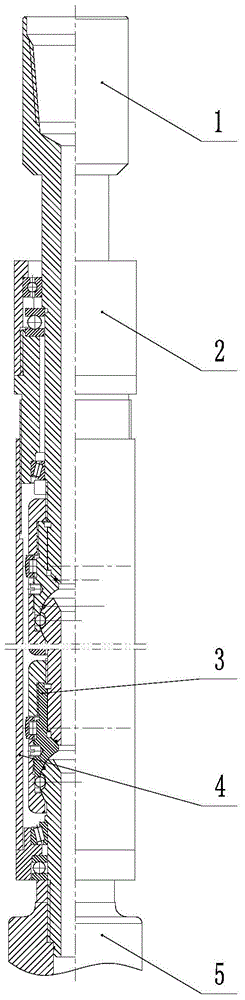

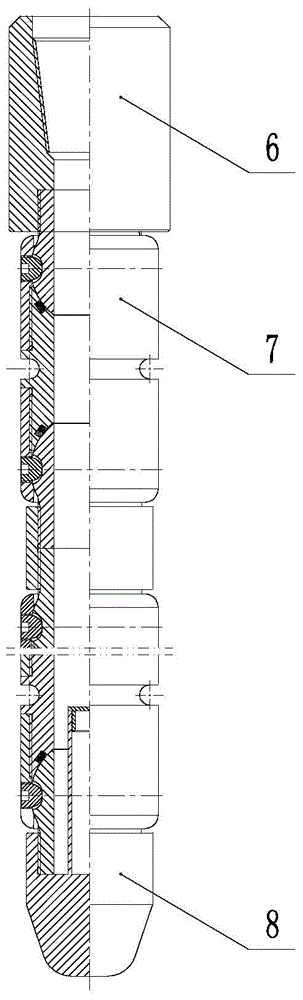

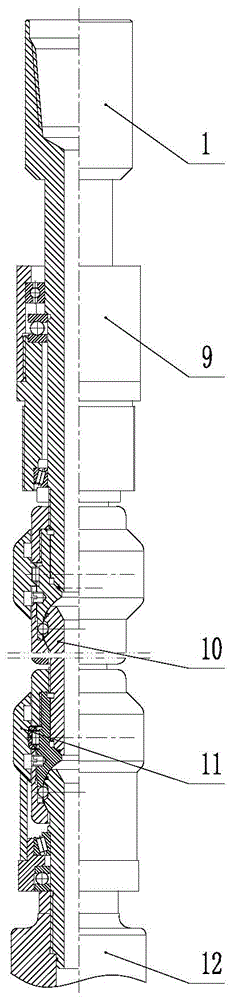

[0025] The present invention will be further described below in conjunction with the accompanying drawings:

[0026] Depend on Figure 1 to Figure 4 As shown, an ultra-short radius radial sidetracking horizontal well method includes the following steps:

[0027] (1), wellbore preparation

[0028] (1) Open the well to make the wellbore unobstructed;

[0029] (2) Measure by gyroscope to master the trajectory of the old well;

[0030] (3) Pressure test of the upper casing to understand the integrity of the casing;

[0031] (4) Check the relevant information of the old well, understand the cementing quality, and provide the pressure coefficient of the offset well;

[0032] (5) Clean the inner wall of the casing.

[0033] (2), lowering the inclined device

[0034] Use the Ф73 positive buckle drill pipe to lower the tilter to the specified well depth, use the logging truck to lower the gyroscope into the positioning joint above the tilter, and determine the angle required by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com