Deflector ring for exhaust hood of turbine

A technology of diversion rings and exhaust cylinders, which is applied in the field of diversion rings, and can solve problems such as uneven distribution of streamlines at the outlet, low expansion capacity of exhaust cylinders, and large total pressure loss of exhaust cylinders.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing:

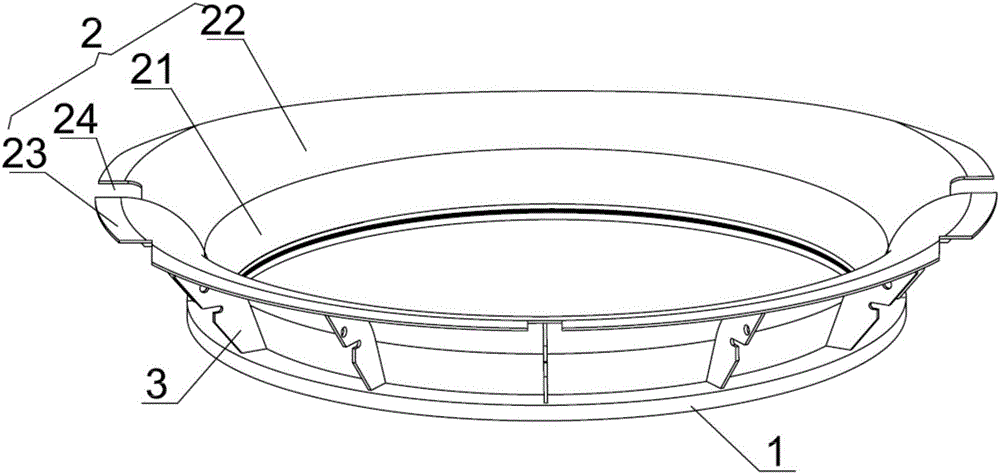

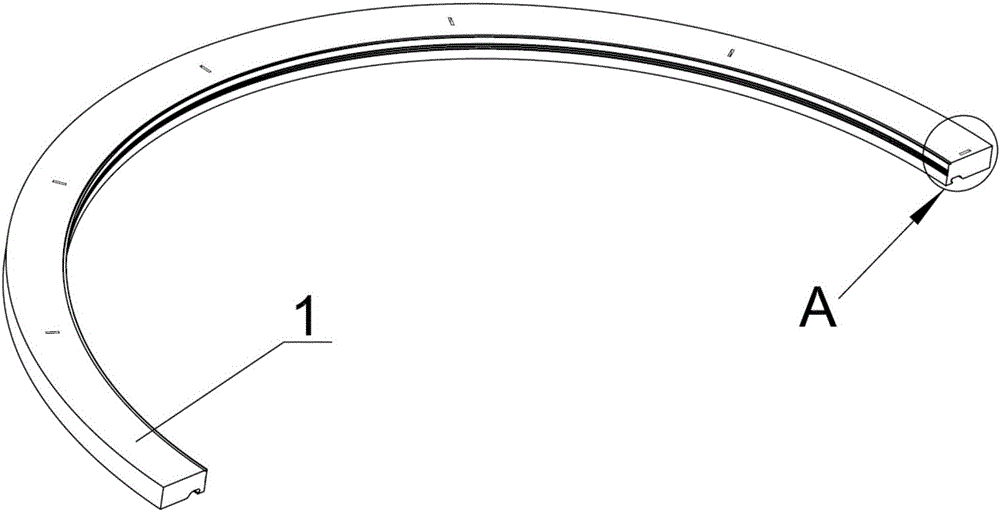

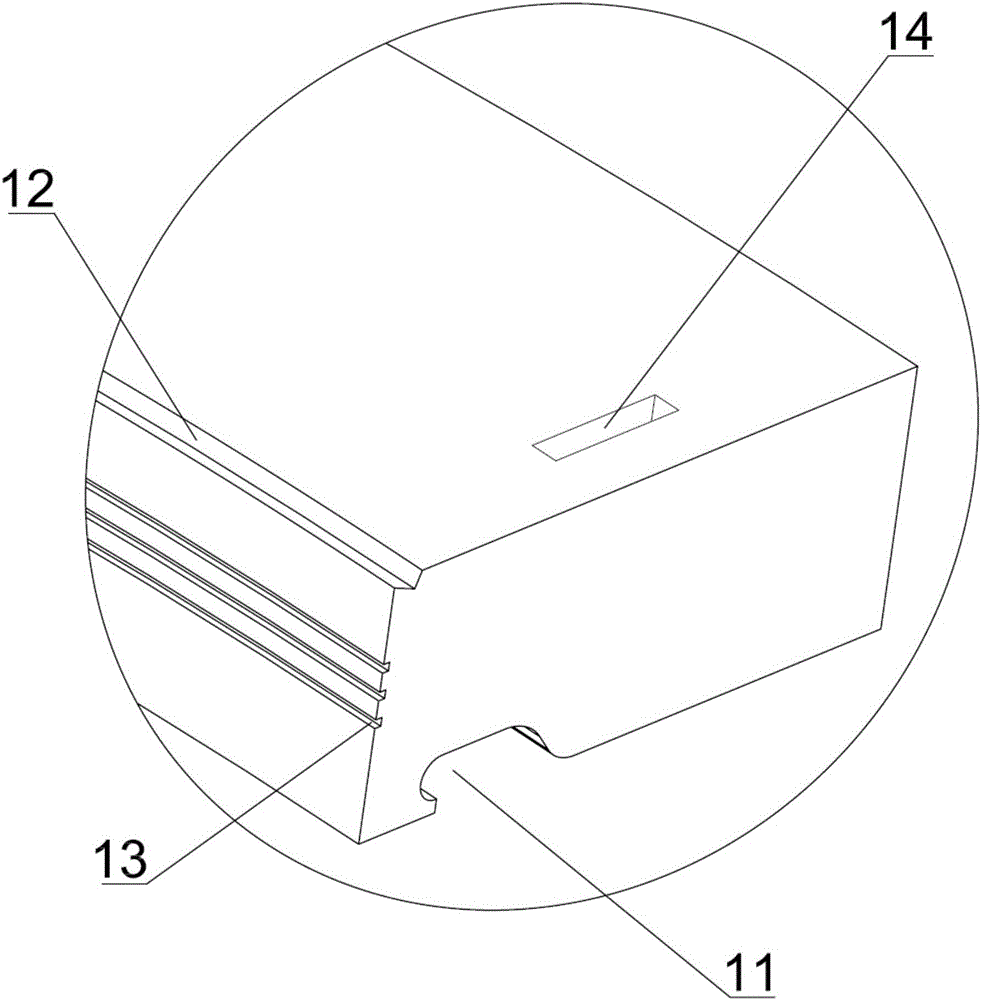

[0021] The invention provides a guide ring for steam turbine exhaust cylinder, as attached figure 1 As shown, it includes a flange assembly 1 and a ring plate assembly 2 fixedly connected with the flange assembly 1 . as attached figure 2 And attached image 3 As shown, the lower surface of the flange assembly 1 is provided with an annular sump 11, and the annular sump 11 drains away the accumulated water of the final stage blade to protect the final stage blade in the exhaust cylinder; the upper surface of the flange is provided with a connecting ring plate assembly 2 Install the positioning spigot 12, the inner wall of the flange assembly 1 is provided with a steam seal installation groove 13, and the steam seal installation groove 13 is used to install the steam seal sheet; the upper surface of the flange assembly 1 is provided with a rib positioning groove 14 that def...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com