Noiseless fan facilitating heat dissipation

A quiet and convenient technology, which is applied to components, instruments, and electrical digital data processing of elastic fluid pumping devices to achieve improved heat dissipation, low noise, and good heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

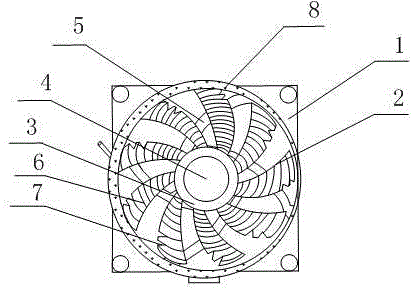

[0016] Such as figure 1 As shown, the present invention includes a stator 4 and a rotor, and the stator 4 includes a bearing, a coil and a circuit board, and multi-turn coils are wound on the bearing, and the bearing is vertically installed on the top of the circuit board; the rotor includes a plurality of fan blades 2, The ring magnet 3 and the shaft are evenly arranged on the surface of each fan blade 2 along the counterclockwise flow guide line 6, the ring magnet 3 is sleeved on the shaft, and a cavity is formed between the ring magnet 3 and the shaft, and the bearing and The central hole of the circuit board is set on the shaft, and a rubber sleeve is also sleeved outside the ring magnet 3. On the side of the rubber sleeve, there is a circle of fan blades 2 evenly radiating. The fan blades form an acute angle with the vertical direction. The entire stator 4 and The rotors are installed in the circular cavity formed by the base 1, and a circular ring is installed on the inn...

Embodiment 2

[0019] This embodiment is preferably as follows on the basis of Embodiment 1: In order to facilitate the addition of heat exchange fluid and the discharge of heat exchange fluid with a high temperature, an inlet for adding liquid is also provided on the side wall of the circular circle. The bottom also is provided with the outlet that puts liquid.

[0020] The heat exchange liquid 8 is an aqueous solution.

[0021] A plurality of notches 7 are provided on one side of each fan blade 2 , and each notch 7 has a V-shaped structure. The design of the notch can quickly divert part of the wind pressure while ensuring the same air volume, reducing the large noise generated by the friction between wind pressure and air.

[0022] The ends of a ring of fan blades 2 uniformly radiating on the side of the rubber sleeve are all deflected counterclockwise, and the width of each fan blade 2 is between 8-15 cm. It can make each fan blade contact with more air area, and more airflow can pass ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com