Tilting pad bearing capable of monitoring residual pump axial force on line and testing method thereof

An axial force and bearing technology, used in mechanical bearing testing, shafts and bearings, bearings in rotating motion, etc., can solve the problems of inaccurate results and increase costs, and achieve the effect of accurate measurement values and accurate measurement display.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

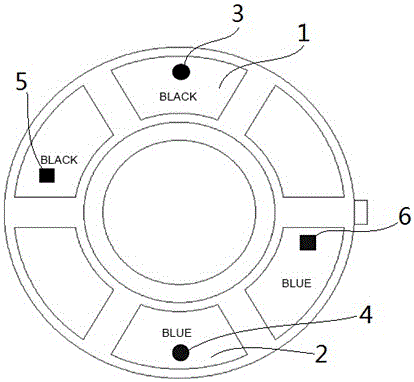

[0018] Such as figure 1 As shown, the present invention provides a tilting pad bearing that can monitor the residual axial force of the pump on-line, including the tilting pad bearing, and the tilting pad bearing includes six arc-shaped pads. The tilting pad bearing is provided with a test element and a display instrument electrically connected to the test element. A hole is opened on the back of the tilt pad bearing, and the test element is placed in the hole. The test element includes a measuring Pressure components and temperature measuring components.

[0019] Specifically, the load cells are the top load cell 3 placed on the back of the top arc-shaped tile 1 and the bottom load cell 4 placed on the back of the bottom arc-shaped tile 2 . And the two load measuring elements are symmetrical to the center of the tilting pad bearing. Correspondingly, there are two temperature-measuring elements, which are placed on the back of the arc-shaped tile adjacent to the load-measuri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com