A zinc/air battery pack

A technology for air battery packs and single cells, which is applied to hybrid batteries, circuits, electrical components, etc., can solve problems such as blockage of liquid injection connectors, and achieve the effects of convenient secondary replacement, easy implementation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

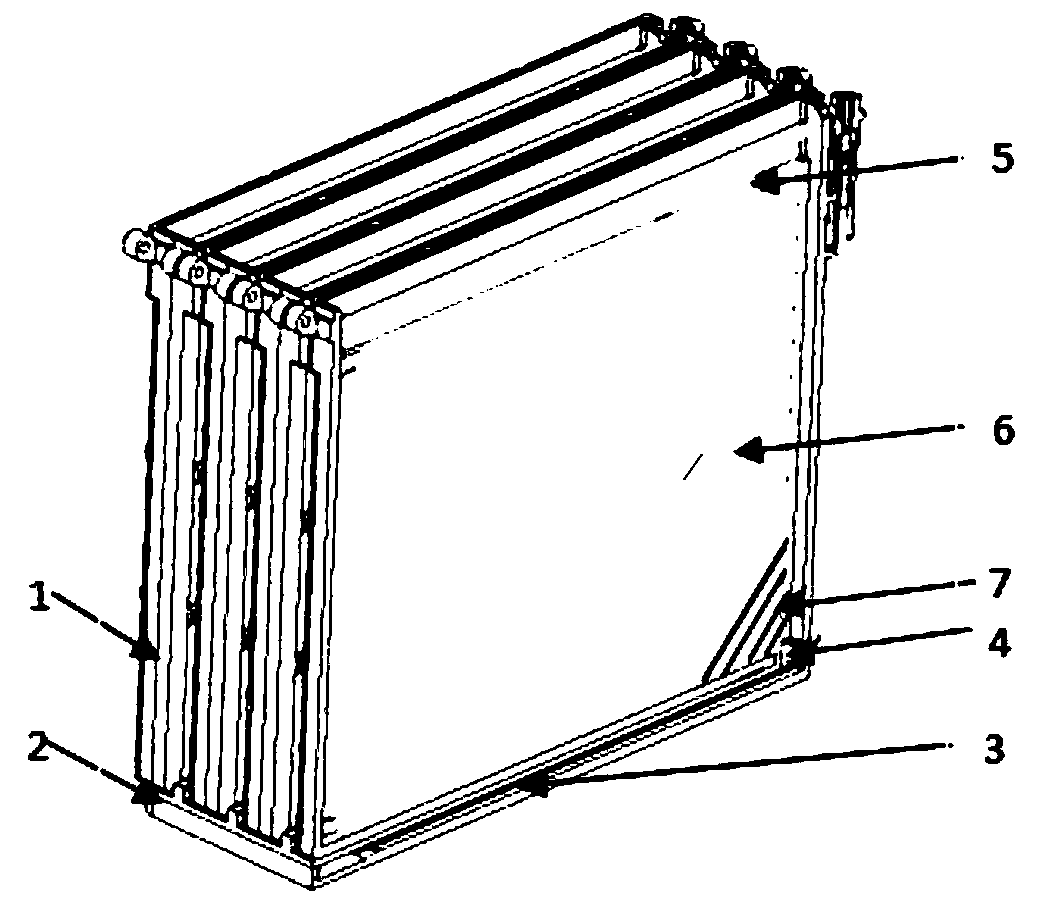

[0022] A zinc / air battery pack, including 24 planar single cells stacked in sequence, the single cell includes a single cell casing, an air cathode, a zinc anode, and an electrolyte chamber between the air cathode and the zinc anode, and the single cell The electrolyte chamber between the batteries is connected in series through a liquid injection connector. The diameter of the flow channel of the connector is 5mm. The zinc anode is a zinc paste electrode formed by mixing zinc powder and binder, and the zinc anode is covered with a diaphragm. The size of the diaphragm bag is 160mm*120mm*3mm. The outer surface of the contact area between the diaphragm bag and the electrolyte connection port is coated with water-blocking glue. The composition of the water-blocking glue is 60% acetone, 10% dichloroethane, The content of ABS is 30%. Take the above-mentioned substances in proportion, stir them until they are evenly mixed, and coat them on the outer surface of the contact area betwee...

Embodiment 2

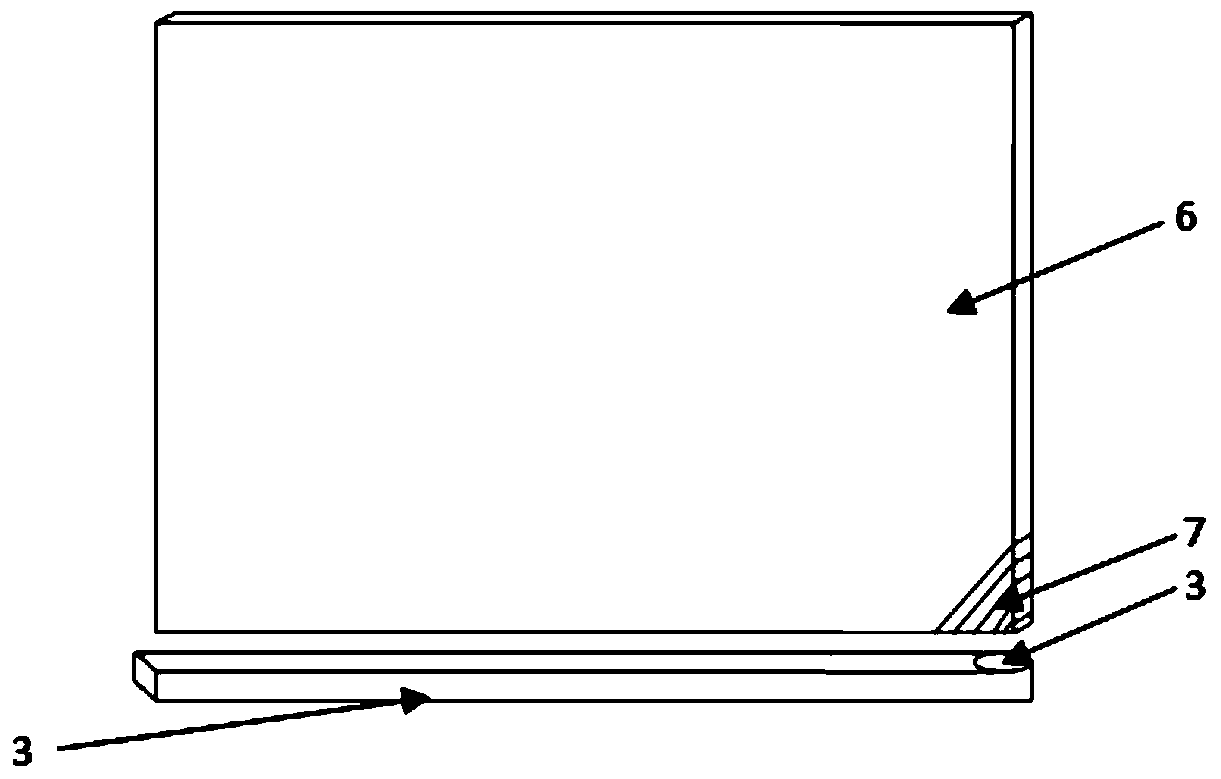

[0025] The composition of the water-blocking glue in Example 1 is 50% toluene, 10% dichloromethane, and 40% polystyrene. Take the above-mentioned substances in proportion, stir until they are evenly mixed, and apply them on the diaphragm bag and contact with the electrolyte communication port. The outer surface of the area is solidified for 24 hours, and the coated area is figure 2 Each face of a triangular prism with a middle right-angled side length of 10mm.

Embodiment 3

[0027] In Example 1, the water-blocking glue is commercialized epoxy resin AB glue, and after mixing evenly, it is coated on the outer surface of the contact area between the diaphragm bag and the electrolyte communication port and solidified for 24 hours. The coating area is figure 2 Each face of a triangular prism with a middle right-angled side length of 10mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com