Air Spring Vibration Isolator with Diaphragm

An air spring and vibration isolator technology, applied in the direction of gas shock absorbers, springs/shock absorbers, springs, etc., can solve the problems of poor air tightness, single structure, complex structure, etc., and achieve good vibration reduction effect. The effect of fast dynamic response and large vibration damping displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The structure of the vibration isolator with diaphragm of the present invention will be further described in detail below in conjunction with the accompanying drawings.

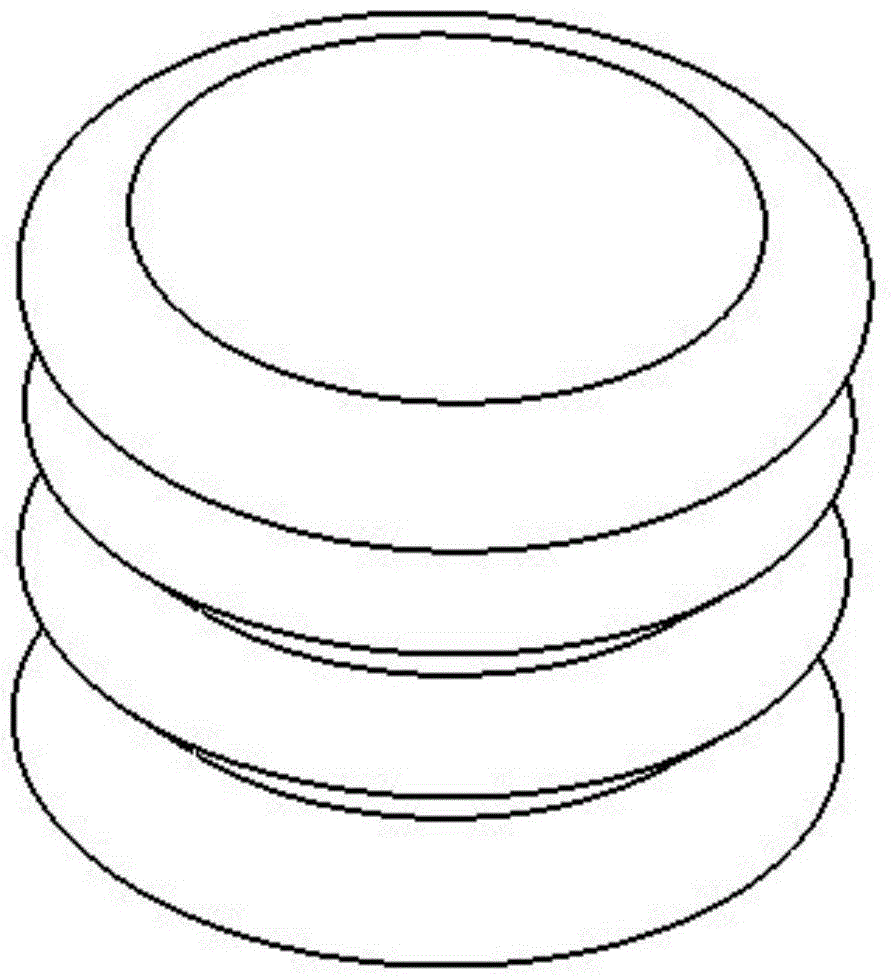

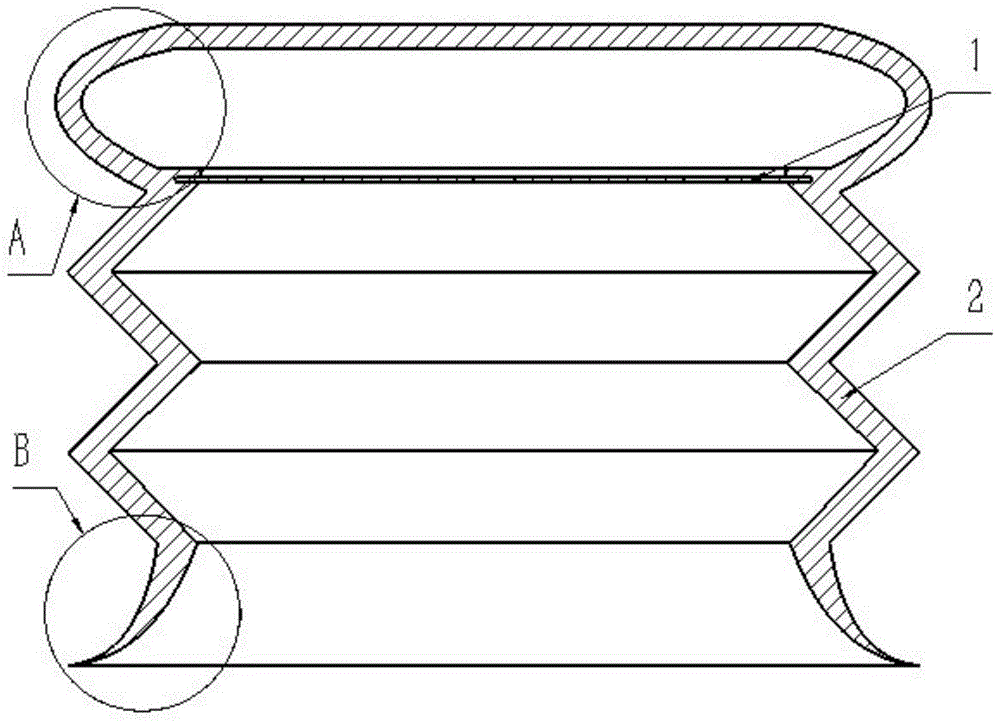

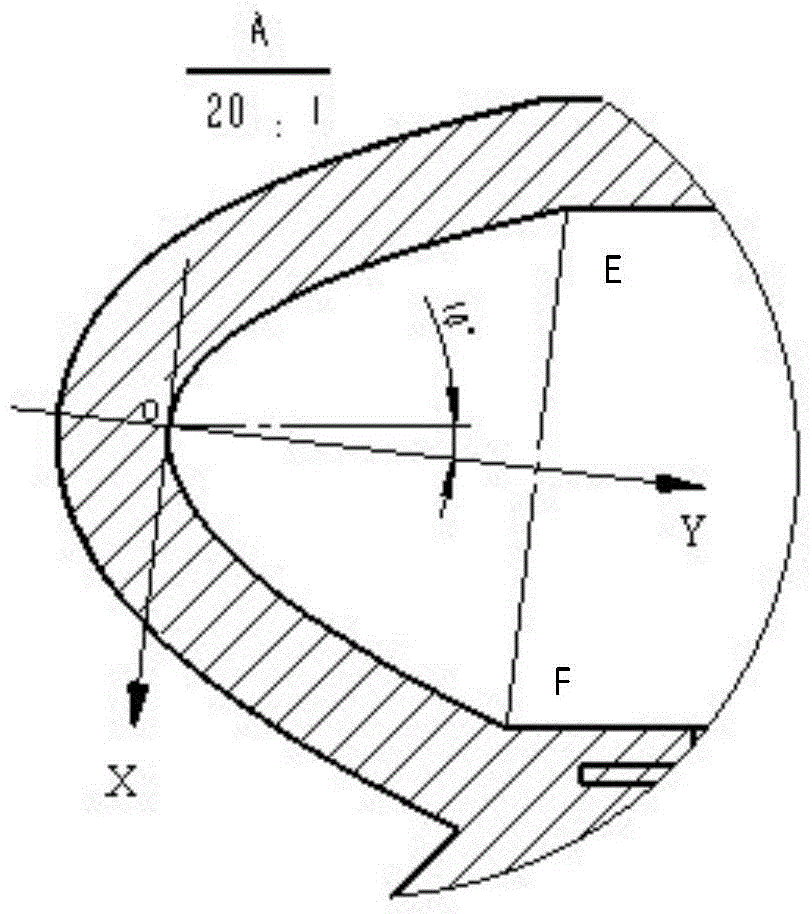

[0026] see figure 1 and figure 2 , the present invention is an air spring vibration isolator with a diaphragm, the vibration isolator includes an internal diaphragm 1 and a shell 2, the internal diaphragm 1 has a small damping hole 3, which divides the internal air into upper and lower parts, and the small damping hole 3 can To realize the gas exchange between the upper airbag and the lower airbag, the shell part of the upper airbag is designed according to the parabolic curve; the shell part of the lower airbag is divided into upper and lower parts, the upper part is a zigzag structure, and the lower part is designed according to the spline curve. see image 3 , the upper end of the vibration isolator of the present invention is in contact with the bottom of the electronic equipment, and the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com