Hydraulic-drive stepless speed changing gearbox for crawler-type spraying machine

An inorganic variable speed and sprayer technology, applied in the field of gearboxes, can solve the problems of low height and high strength of the sprayer, and achieve the effect of high strength, not easy to damage, and reduced height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

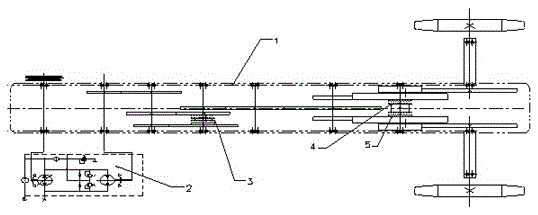

[0016] like figure 1 The illustrated crawler sprayer uses a hydraulically driven inorganically variable gearbox, including a gearbox and a hydraulic continuously variable gearbox 2 connected to the input end of the gearbox.

[0017] The gearbox of the technical solution of the present invention includes a box body 1 and a reduction gear set built in the box body 1. The box body 1 is integrally formed in the shape of a cuboid and arranged horizontally. One end of the box body 1 is bent downward.

[0018] The reduction gear set of the technical solution of the present invention includes a first transmission shaft, a second transmission shaft, a third transmission shaft, a fourth transmission shaft, and a fifth transmission shaft installed in the casing 1 sequentially from the input end to the output end of the casing 1 , the sixth transmission shaft, the seventh transmission shaft, the eighth transmission shaft and the ninth transmission shaft positioned below the fourth transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com