An oil drilling diesel engine fixing device

A fixed device and oil drilling technology, which is applied in the petroleum field, can solve the problems of diesel engine displacement, high diesel engine power, poor fixing reliability, etc., and achieve the effects of preventing vibration, stabilizing oil production and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

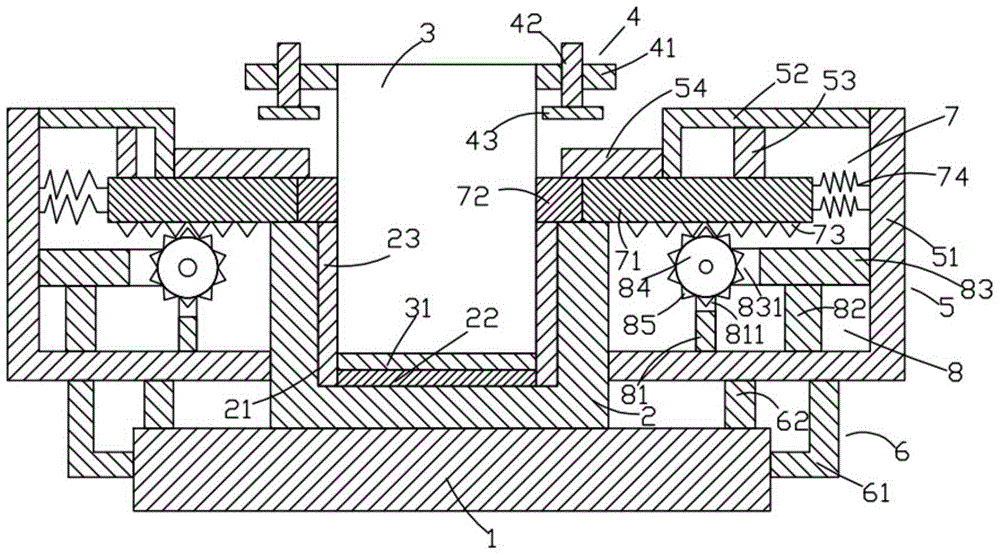

[0019] like figure 1 As shown, the oil drilling diesel engine fixing device of the present invention includes a base 1, a fixing frame 2 located above the base 1, a fixing block 3 inside the fixing frame 2, and fastening devices located on the left and right sides of the fixing block 3 4. The positioning device 5 , the moving device 7 arranged on the positioning device 5 , the rotating device 8 located below the moving device 7 , and the supporting devices 6 located on the left and right sides of the base 1 .

[0020] like figure 1 As shown, the base 1 is in the shape of a cuboid, and the base 1 is placed horizontally. The cross-section of the fixed frame 2 is concave, and the lower surface of the fixed frame 2 is fixedly connected with the upper surface of the base 1 . The fixing frame 2 is provided with a receiving cavity 21 inside, a friction block 23 inside the receiving cavity 21 , and a first magnet 22 on one side of the friction block 23 . The accommodating cavity 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com