A gravity heat pipe system that can rotate with the lamp in the range of 0°-90°

A technology of gravity heat pipes and lamps, which is applied to cooling/heating devices of lighting devices, lighting and heating equipment, semiconductor devices of light-emitting elements, etc., can solve the problems of inability to realize the gas-liquid phase change cycle of working medium, and inability to achieve heat dissipation effects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

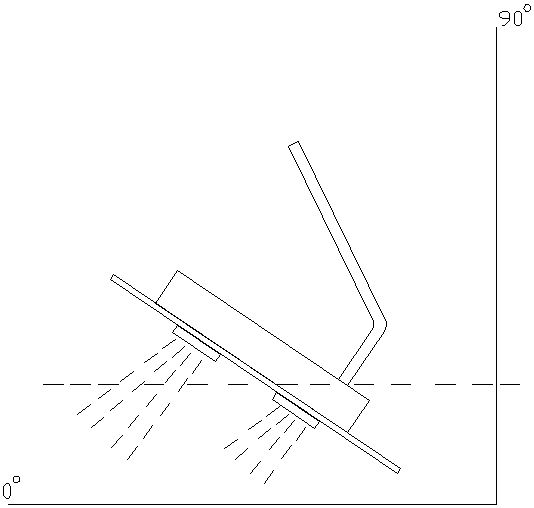

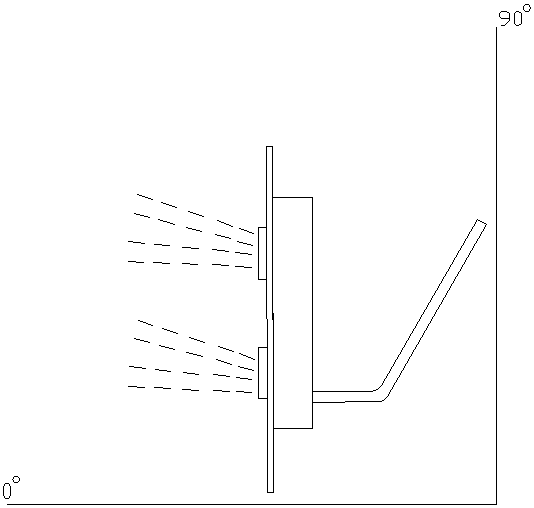

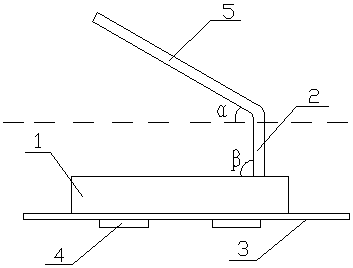

[0015] For a clearer description, the case where α=30° and β=90° are described as an example. Based on the horizontal placement of the bottom surface of the evaporation chamber 1, that is, the thermal contact surface 3, an LED light source 4 is attached to the thermal contact surface 3. Place the heat pipe radiator 5 and the thermal contact surface 3 at an angle of α=30° to determine the axis of rotation and The intersection of the heat pipe radiator 5 and the thermal contact surface 3 is parallel or coincident, and the connecting pipe 2 connects the heat pipe radiator 5 and the evaporation chamber 1 according to β=90°, that is, the direction perpendicular to the thermal contact surface 3. The whole lamp is around the axis of rotation, Rotate and irradiate in the range of 0°-90°. During the rotation, the working fluid in the heat pipe system can realize normal gravity circulation to achieve efficient heat dissipation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com