Dryer with material dispersing device arranged on material storage layer

A dryer and bulk material technology, which is applied in the direction of drying solid materials, drying, lighting and heating equipment, etc., can solve the problems of increasing the material consumption of the dryer and increasing the difficulty of installation, so as to reduce the difficulty of installation, facilitate the start-stop and The effect of replacing and improving the monitoring ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The overall structure of the drying machine involved in the present invention is the same as that of the traditional drying machine, the difference is that the storage layer of the drying machine involved in the present invention adds a bulk material device, therefore, the overall structure of the drying machine involved in the present invention will not be repeated , only the storage layer is introduced in detail.

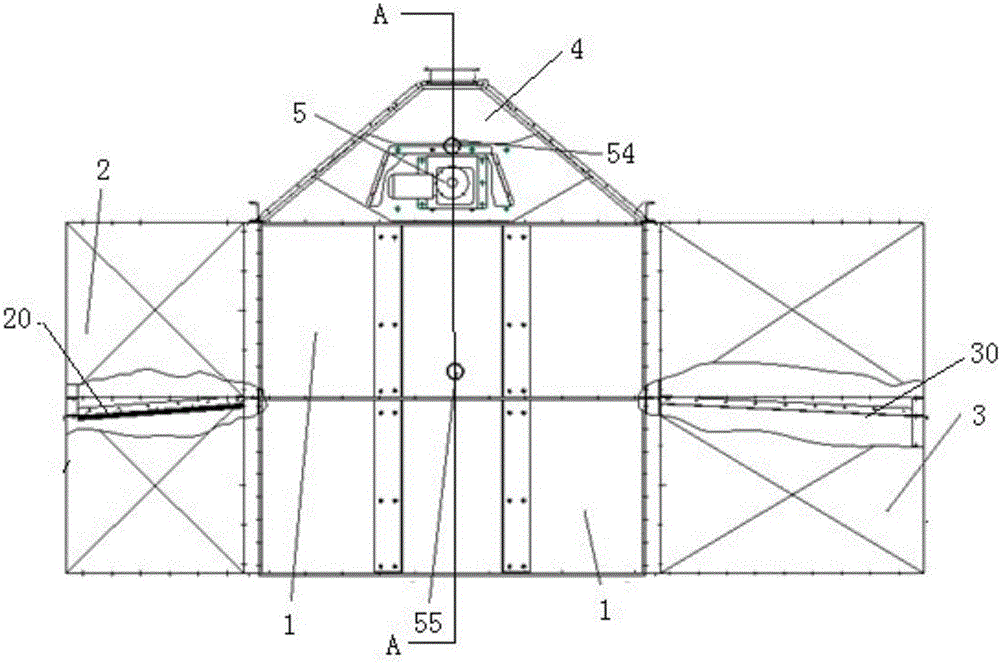

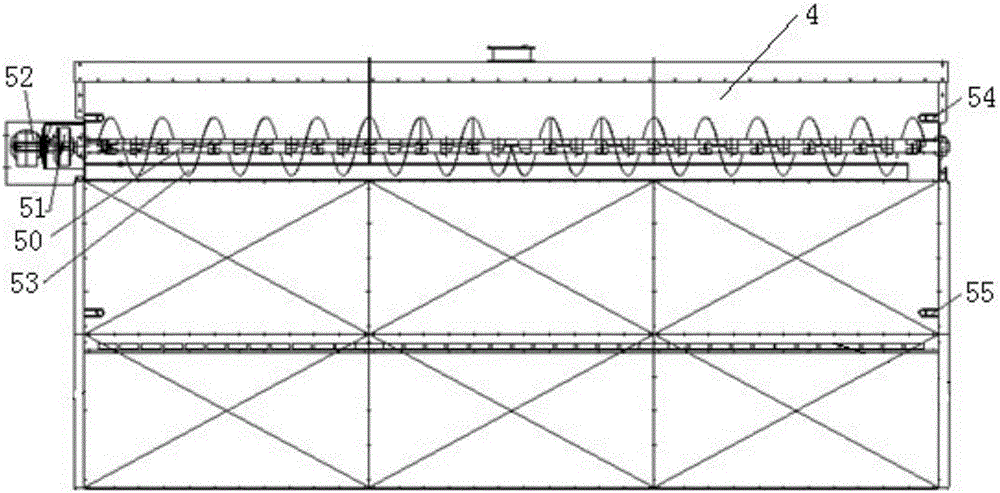

[0018] Such as figure 1 , figure 2 As shown, the present invention comprises two layers of continuous material storage layers 1, one side of the material storage layer 1 is provided with an air inlet channel 2, the other side of the material storage layer 1 is provided with an air outlet channel 3, and the material storage layer 1 at the top A T-shaped feed unit 4 is arranged above the top of the feed unit 4, and a bulk material device 5 is arranged in the feed unit 4. The bulk material device 5 comprises a bulk material shaft 50 arranged between the for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com