Preparation method for directional hole ceramic enhanced metal matrix composite material

A composite material and directional hole technology, which is applied in the field of composite material preparation, can solve the problems of low compressive strength and bending strength, and achieve the effect of avoiding agglomeration and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

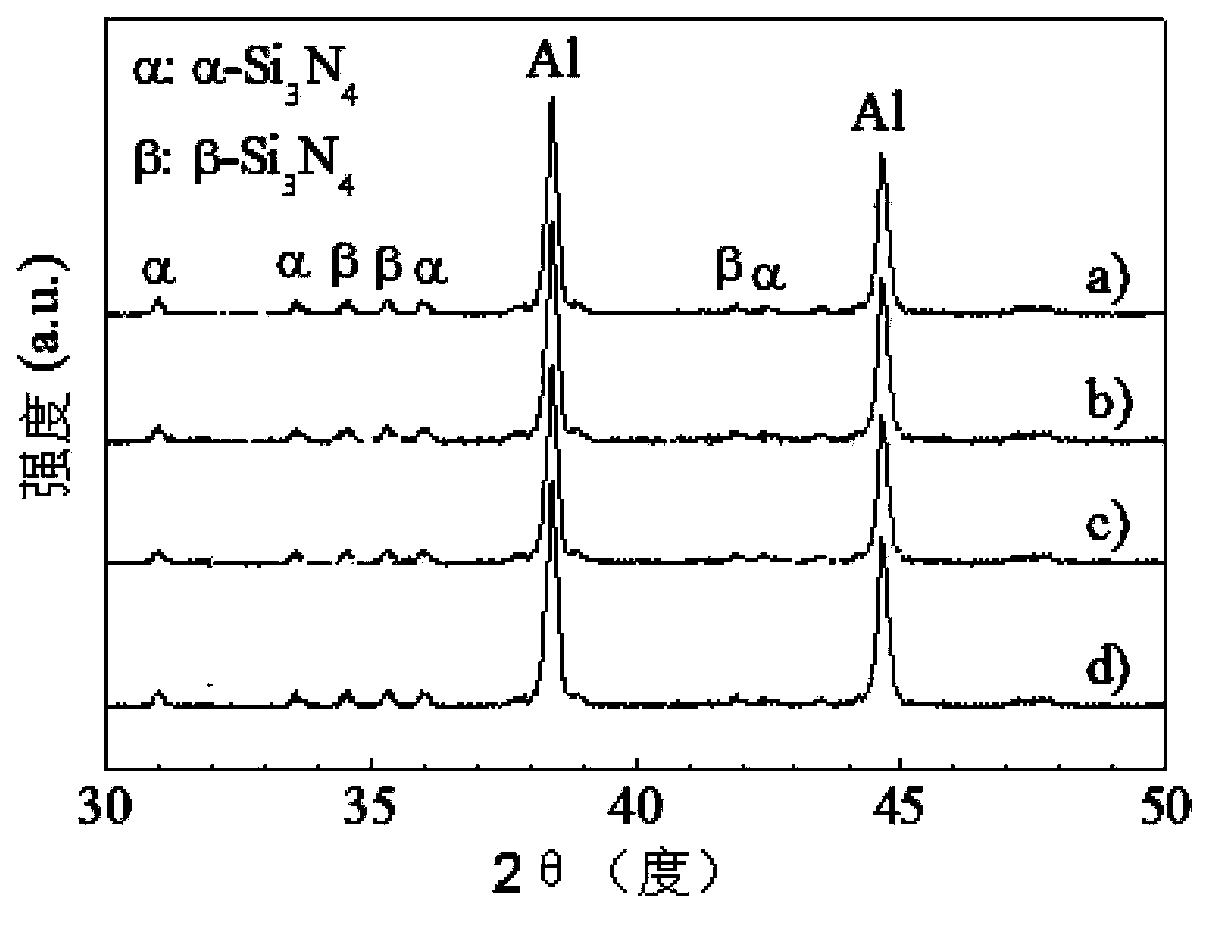

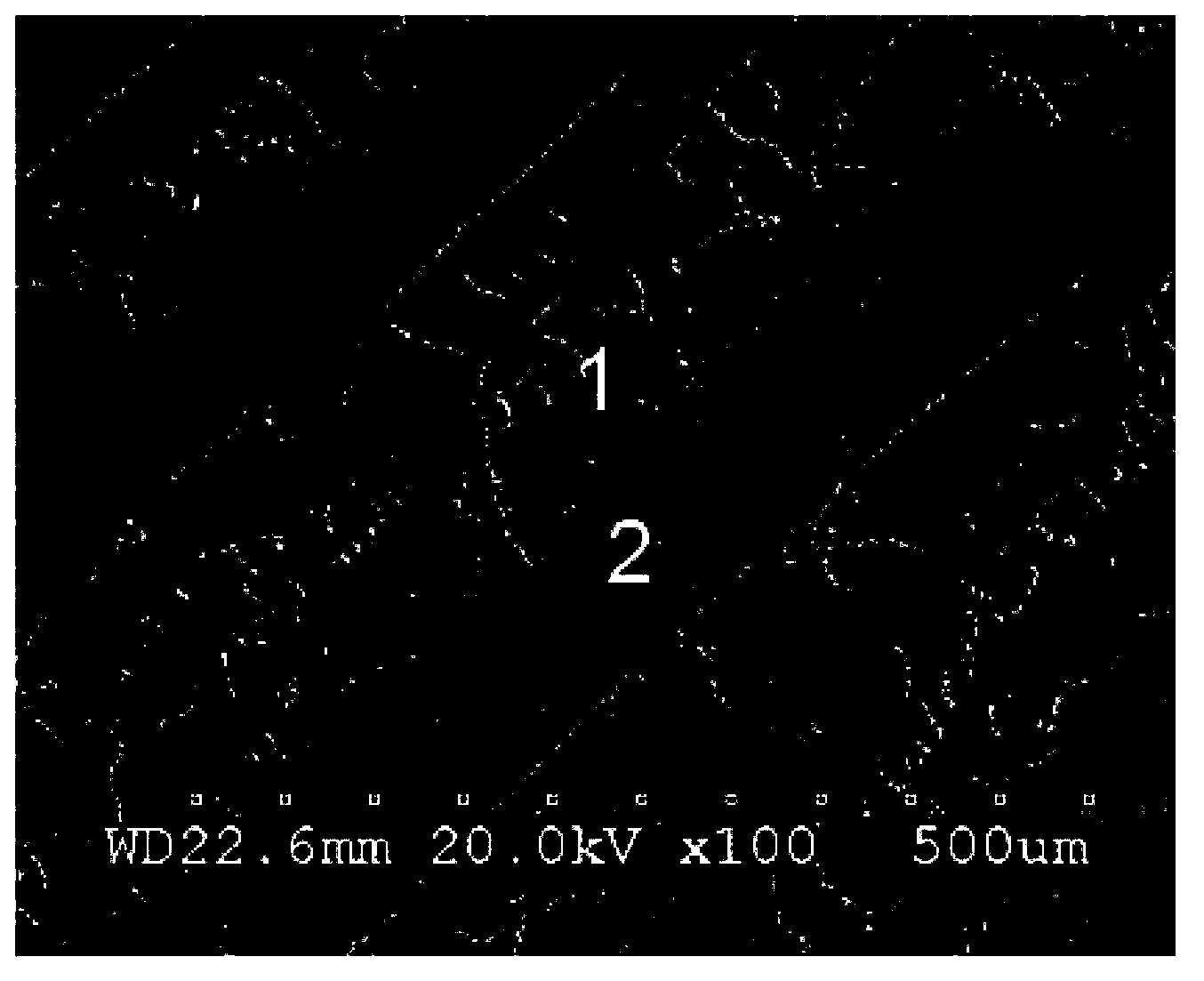

[0022] Specific implementation mode 1: The preparation method of the directional hole ceramic reinforced metal matrix composite material in this implementation mode is carried out according to the following steps:

[0023] 1. Mix the raw materials and deionized water according to the volume ratio of 3:2 to obtain a mixture. The raw materials are SiC powder and Y 2 o 3 Composition, the mass content of SiC powder in the raw material is 95%, Y in the raw material 2 o 3 The mass content of SiC powder, dispersant, binder and defoamer is 1:0.005:0.01:0.001, and then the dispersant, binder and defoamer are added to the mixture , and then add silicon nitride balls for ball milling for 24 hours to obtain a slurry;

[0024] 2. Degas the slurry for 10 minutes, then pour the degassed slurry into a mold to form a sample, keep the sample at 0°C-10°C for 5-120 minutes, and then heat it at a temperature of -10-40°C 1. Freeze-drying for 1-4 days under the condition of a pressure of 1-100Pa...

specific Embodiment approach 2

[0027] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the dispersant described in step 1 is tetramethylammonium hydroxide or ammonium citrate. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0028] Embodiment 3: This embodiment is different from Embodiment 1 in that the binder described in step 1 is polyvinyl alcohol, polyvinyl butyral or gelatin. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com