Automobile-used air deflector detection tool

A deflector and inspection tool technology, applied in the direction of using mechanical devices, measuring devices, instruments, etc., can solve the problems of large output of the deflector, inability to perform installation work, and inability to accurately measure the surface difference of the deflector and the deflector. , to achieve the effect of improving detection efficiency and convenient and quick detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

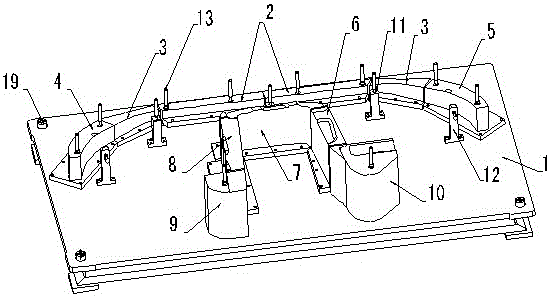

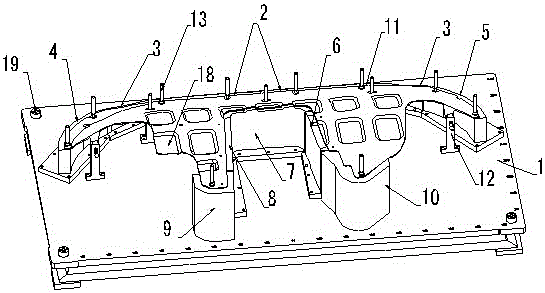

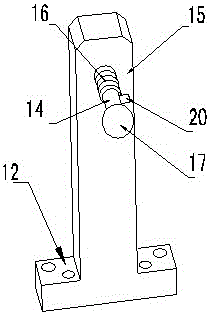

[0015] Depend on figure 1 , figure 2 Known, a deflector inspection tool for automobiles, including a base 1, the base 1 is in a rectangular shape; eleven detection blocks are installed on the base 1 to form a product shape, three detection components 11 and two movable detection supports 12 is installed in the shape of the product enclosed by the detection block; the detection component 11 and some detection blocks are provided with detection pin holes; the eleven detection blocks are composed of two detection blocks I2, two detection blocks II3, one detection block III4, and one detection block Block IV5, one detection block V6, one detection block VI7, one detection block VII8, one detection block VIII9, and one detection block IX10; wherein detection block I2, detection block III4, and detection block IV5 are provided with two detection pin holes; A detection pin hole is arranged on the detection block Ⅷ9 and the detection block IX10. The four corners of the base 1 are p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com