Winding temperature calculation method for fiber temperature controller of transformer

A winding temperature and calculation method technology, which is applied to thermometers, thermometers, and thermometer parts that change physically/chemically, can solve problems such as complicated installation and cumbersome operation, and achieve the goal of simplifying the installation method and improving the calculation accuracy of winding temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Below in conjunction with the embodiment, the transformer model SSZ11-180000 / 220, the voltage ratio 230±8×1.25% / 121 / 10.5, and the connection group YNyn0d11 will further describe the present invention. The following examples are intended to illustrate the present invention rather than further the present invention limited.

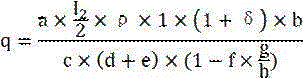

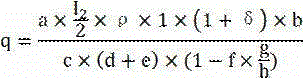

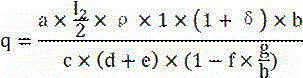

[0043] In this embodiment, the high-voltage side CT ratio K CT , High voltage side rated current I 2 , The thermal load q corresponding to the minimum tap of the transformer is an important performance parameter of the transformer; the thermal load q corresponding to the minimum tap of the transformer is obtained by calculating the parameters such as the rated current, the number of turns of the high-voltage winding and the spacer The performance parameters of the transformer, the calculation formula of q is as follows:

[0044]

[0045] Wherein, a, c are constant; I 2 is the current at the minimum tap on the high-voltage side, unit A; ρ is the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com