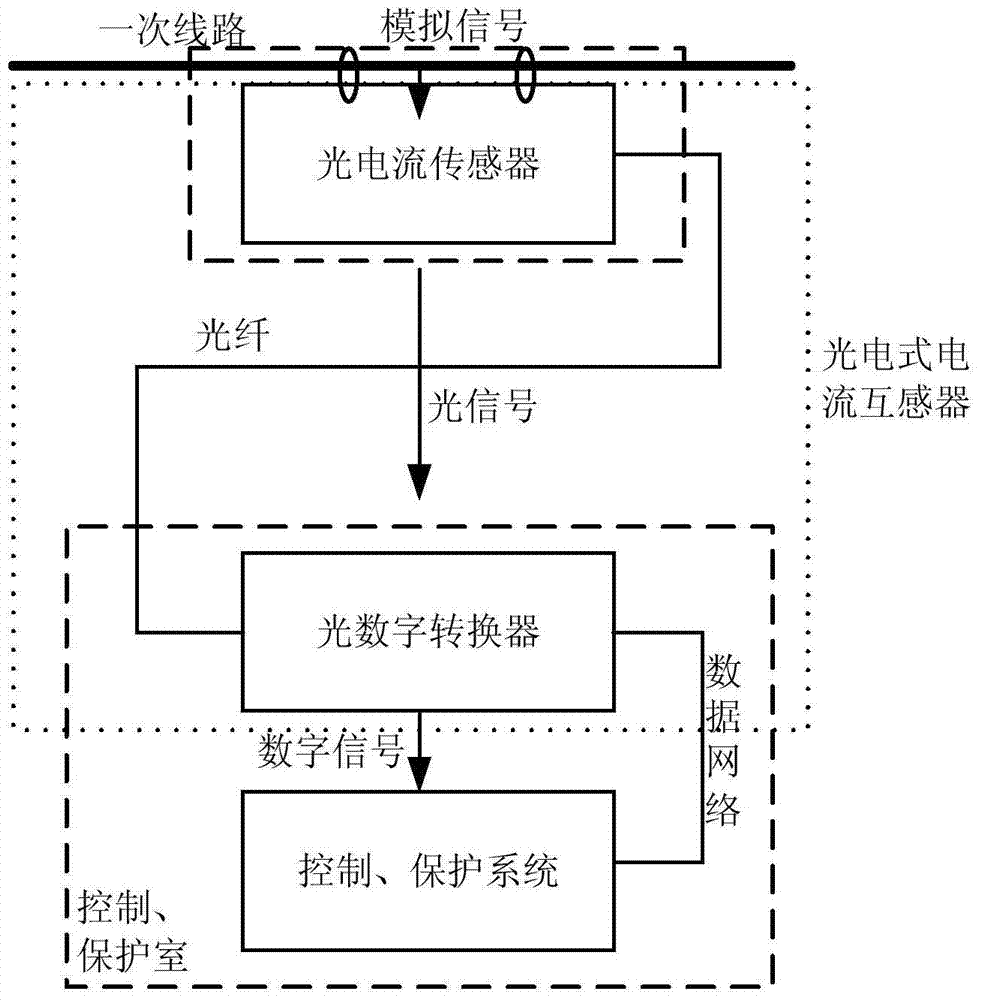

Calibration device and method for a photoelectric current transformer

A technology of current transformer and calibration device, applied in measuring devices, instruments, measuring electrical variables, etc., can solve the problems of high safety risk, time-consuming, labor-consuming, etc., and achieves low safety risk, large application amount, and convenient acquisition. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

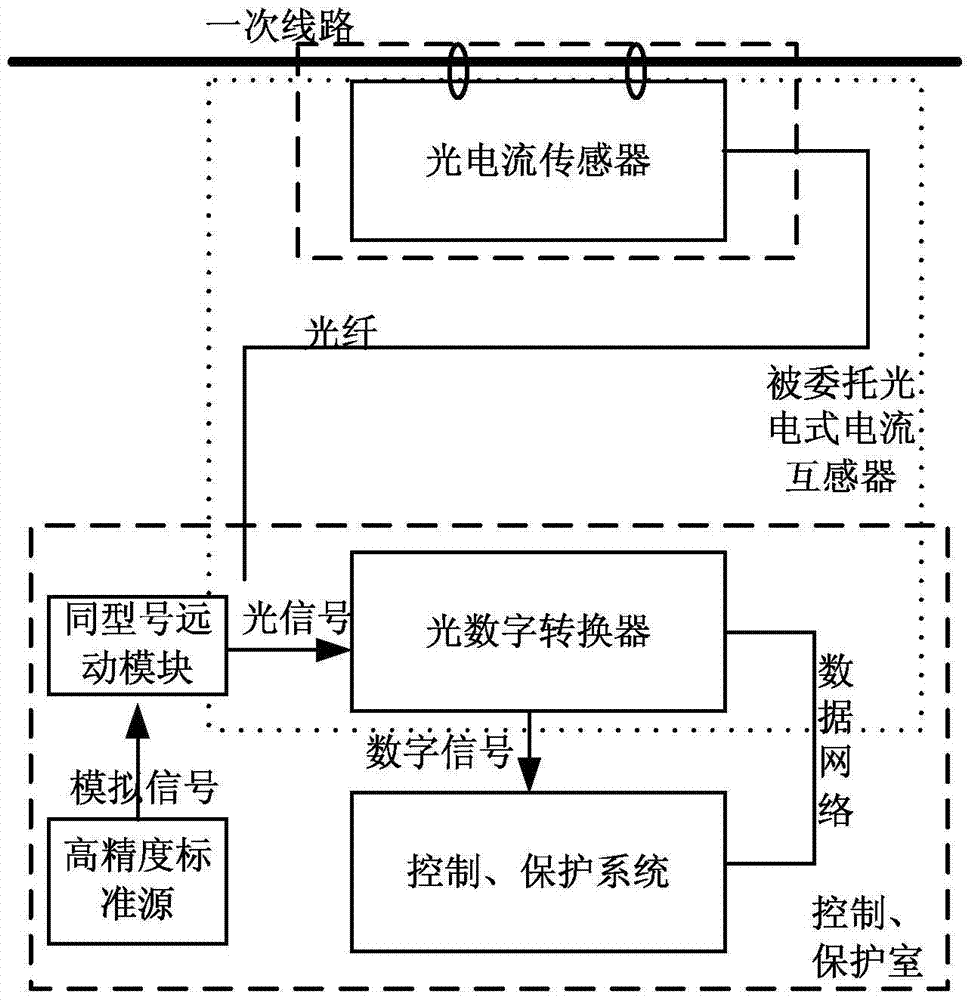

[0034] Such as image 3 A calibration device for a photoelectric current transformer, comprising a voltage source, a telecontrol module (for converting a voltage analog quantity into an optical signal), a photoelectric converter, and a signal acquisition module;

[0035] The photoelectric converter is the photoelectric converter of the photoelectric current transformer to be verified;

[0036] The voltage source is used to generate a voltage signal that simulates the output signal of the photocurrent sensor of the photoelectric current transformer to be verified, and the voltage signal is a voltage analog quantity;

[0037] The voltage source is connected with the telecontrol module to form a virtual measurement channel;

[0038] The telecontrol module converts the voltage analog quantity into an optical signal, and the optical signal is transmitted to the photoelectric converter through an optical fiber as a reference signal for verification, and the photoelectric converter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com