A device for preventing damage to core packs in the automatic assembly machine of aluminum electrolytic capacitors

An aluminum electrolytic capacitor, fully automatic technology, used in capacitors, capacitor manufacturing, circuits, etc., can solve the problems of positive and negative aluminum foil contact, aluminum foil wrinkling, capacitor explosion and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

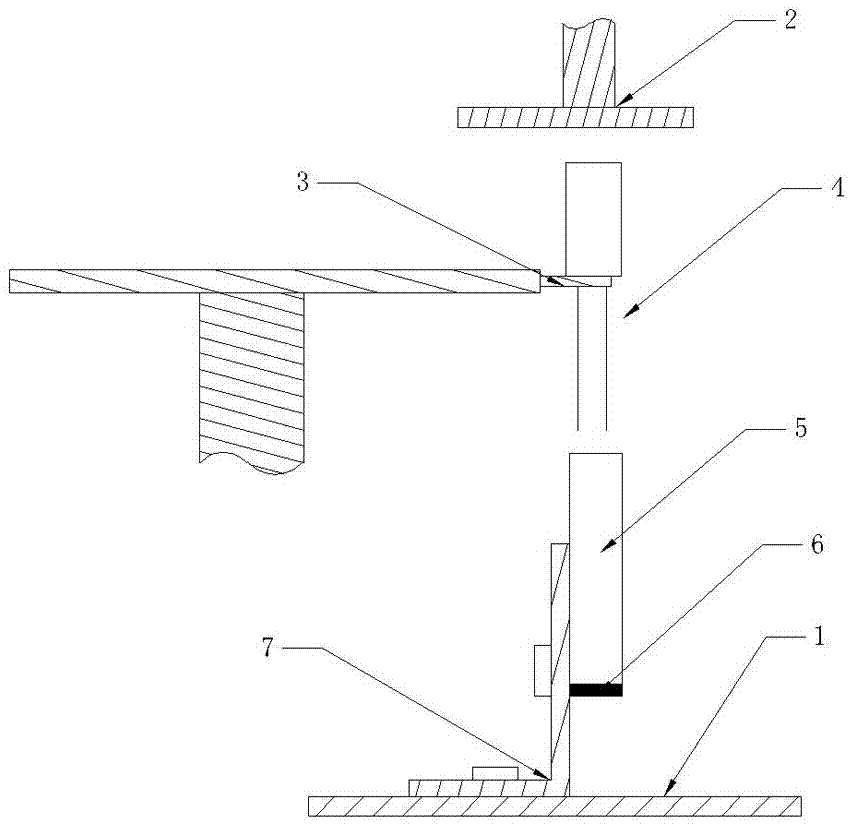

[0025] figure 1 , figure 2 and Figure 5 A device for preventing core package damage of an aluminum electrolytic capacitor automatic assembly machine shown, including a frame platen 1, a core package lower die 2, a positioning damage prevention component of the capacitor and a rotatable chuck 3, positioning and preventing The damage component is set on the frame platen 1, and the core package lower die 2 is relatively set above the positioning damage prevention component to form the assembly space 4 of the capacitor. The chuck 3 holds the core package with the rubber plug and passes through it in turn. Assembling the space 4, applying downward force to the core package through the lower die 2 of the core package and positioning the anti-damage component, so that the lead wire aluminum stem on the core package penetrates the reserved hole of the rubber plug. The positioning anti-damage component includes an electromagnet 5, a base plate 6 and a current regulator. The electro...

Embodiment 2

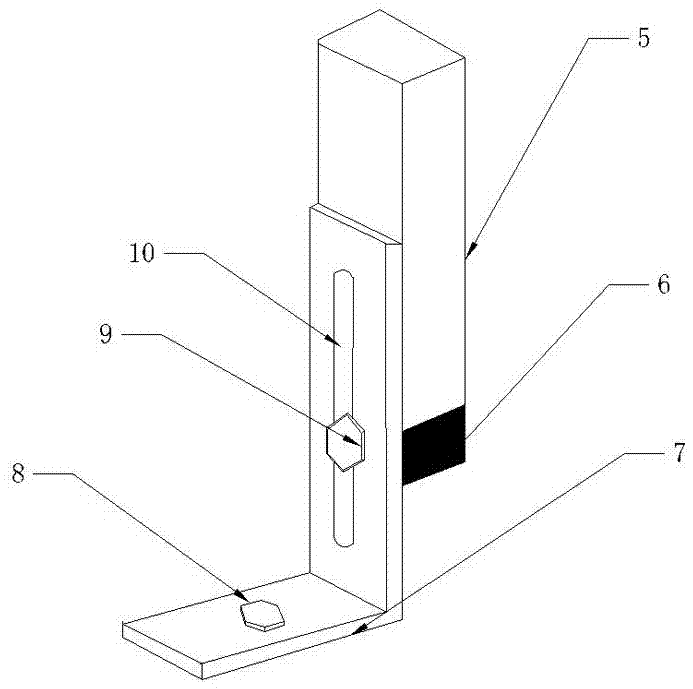

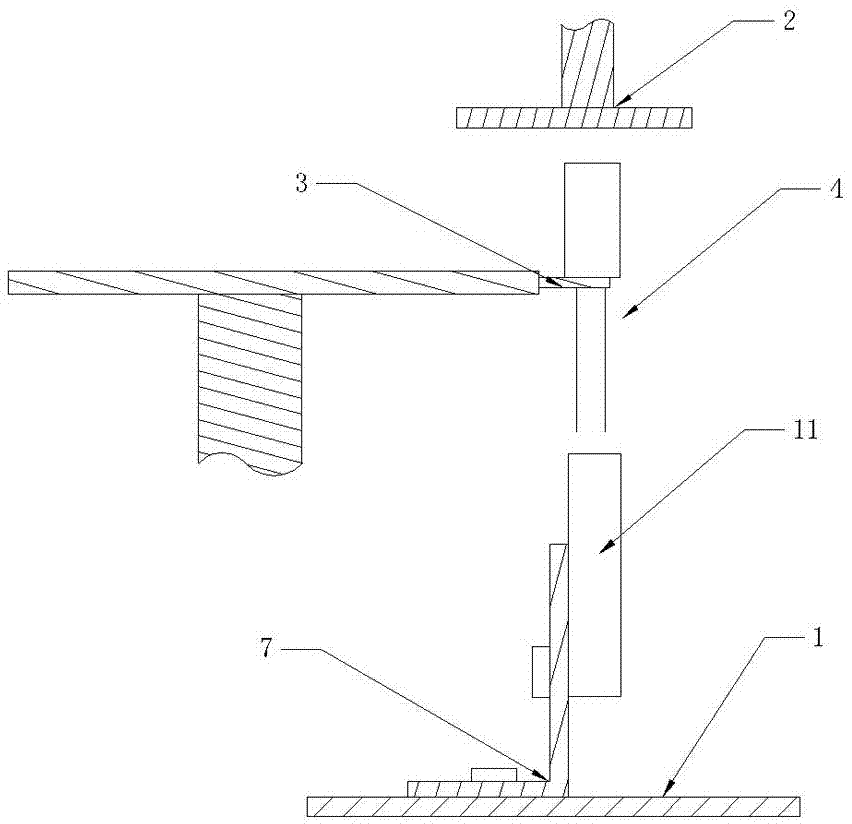

[0030] like image 3 and Figure 4 The positioning and anti-damage components in the device for preventing core package damage of the aluminum electrolytic capacitor automatic assembly machine in this embodiment include permanent magnets 11, height adjustment components and magnet sleeves 12. The permanent magnets 11 are placed in the magnet sleeves 12, and the magnet sleeves 12 Adjust the height with the height adjustment assembly. The height adjustment assembly includes an L-shaped connector 7, a fixing bolt 8 and a positioning bolt 9, the transverse plate of the L-shaped connector 7 is fixed on the frame platen 1 by the fixing bolt 8, and the vertical plate of the L-shaped connector 7 is set There is a font height adjustment hole 10, and the positioning bolt 9 passes through the height adjustment hole 10 and is connected with the magnet sleeve 12 that the permanent magnet 11 is equipped with.

[0031] Other parts of this embodiment are the same as Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com