Method for starting a combustion system

A technology of combustion system and fuel system, applied in combustion method, control combustion, engine starting, etc., can solve problems such as high loss coefficient, and achieve the effect of reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The illustrations in the figures are schematic. It is to be noted that in different figures, similar or identical elements are provided with the same reference numerals.

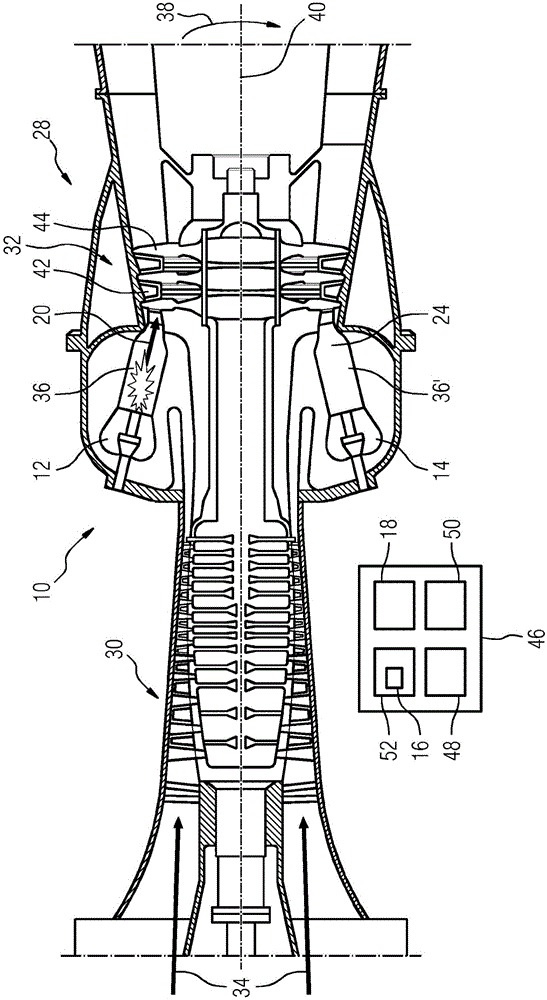

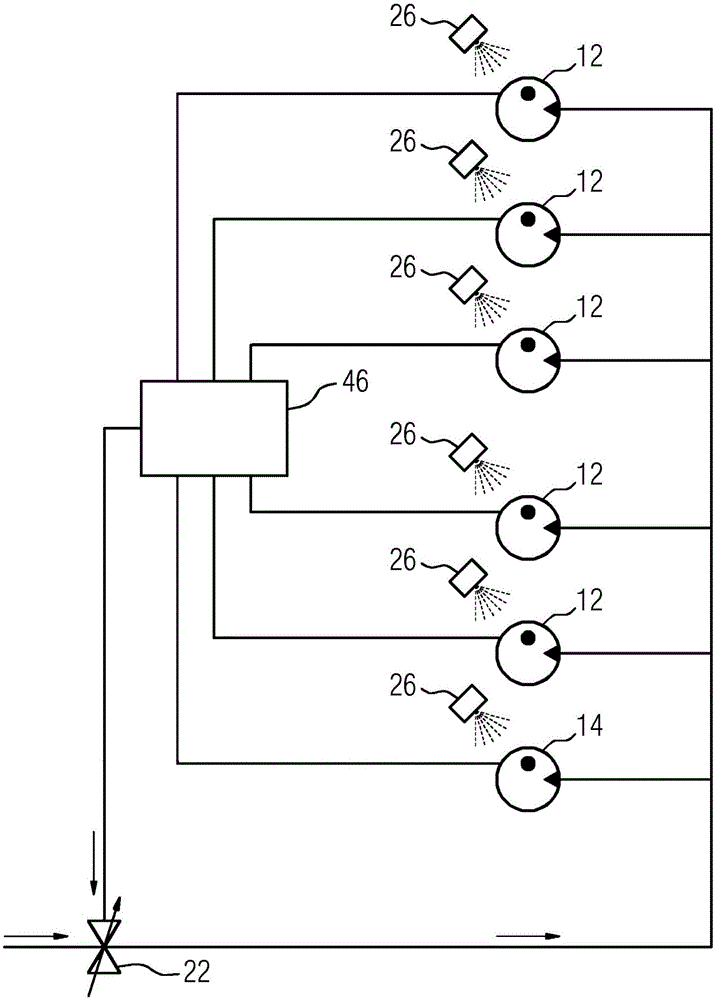

[0046] figure 1 A flow engine 28 , such as a gas turbine, is shown schematically. The flow motor 28 is included in a flow direction 34 of a flow medium, such as air (see figure 1 arrow pointing from the left-hand side to the right-hand side) a compressor 30 , a combustion system 10 and a turbine 32 arranged one behind the other. In the compressor 30 , the incoming fluid medium is compressed for use in one or more combustion chambers of the combustion system 10 . The combustion system 10 comprises in this exemplary embodiment several can-shaped combustion chambers 36, 36' separated by walls not shown and arranged one behind the other in the circumferential direction 38 around the axis 40 of the flow engine 28. In general, it is also possible to design a combustion system with a single annular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com