A liquid metal cooling blade system and anti-corrosion method thereof

A liquid metal cooling, blade system technology, applied in blade support elements, pressure inorganic powder coating, machine/engine, etc., can solve the problems of material strength reduction, affecting the normal use of materials, crushing and falling off, etc., to improve service life. , to ensure reliable and long-lasting operation, improve reliability and the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

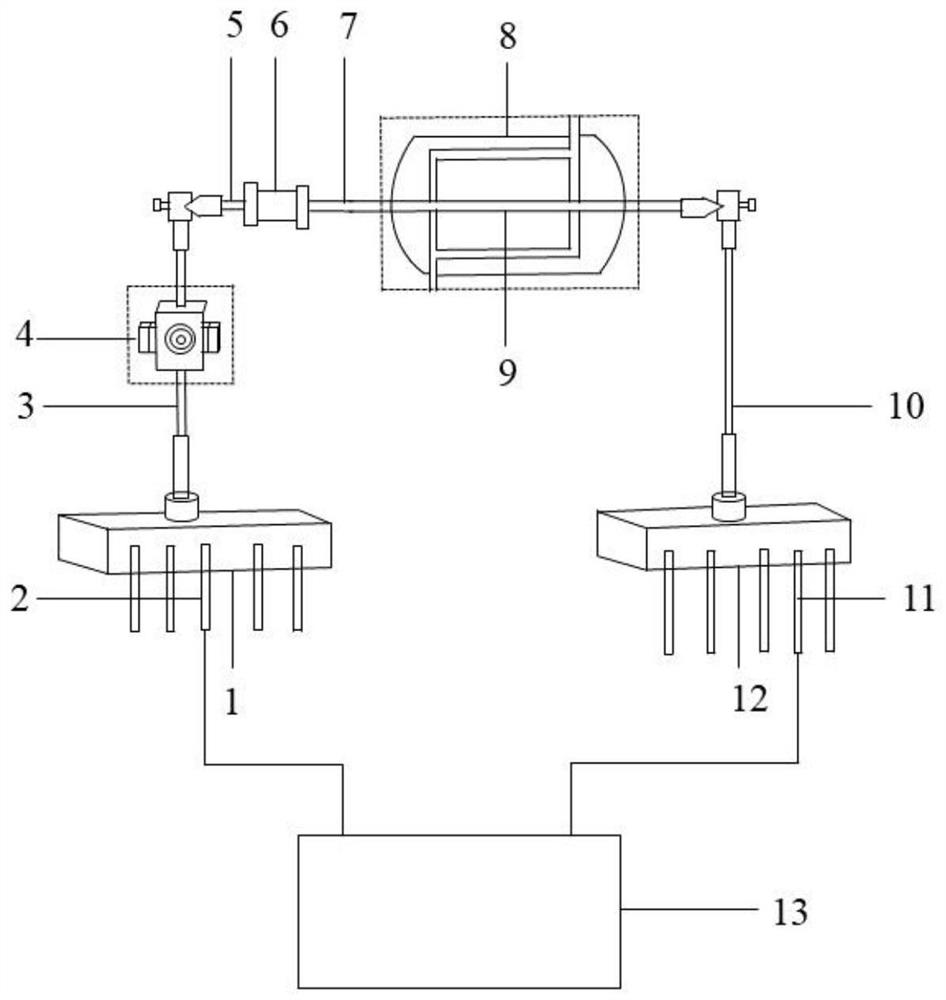

[0034] like Figure 1-2 As shown, a liquid metal cooling blade system proposed by the present invention includes a separator 1, a pipeline A2, a pipeline B3, an electromagnetic pump 4, a pipeline C5, an expansion joint 6, a pipeline D7, a heat exchanger 8, a pipeline F10, and a pipeline G11 , collector 12 and blade 13;

[0035] The heat exchanger 8 is provided with a pipe E9; the pipe E9 is made of but not limited to 1Cr18Ni9 stainless steel or niobium-based alloy or T91 steel; the inner surface of the pipe E9 is provided with Al 2 O 3 protective layer or SiO 2 Protective layer to improve the service life of pipeline E9;

[0036] 1Cr18Ni9 stainless steel or niobium-based alloy or T91 steel are corrosion-resistant metal materials with high temperature resistance and high thermal conductivity. Therefore, corrosion-resistant metal materials with high temperature resistance and high thermal conductivity can be processed into pipeline E9;

[0037] Further, the pipeline E9 is di...

Embodiment 2

[0048] A liquid metal cooling blade system proposed by the present invention, compared with the first embodiment, the present embodiment also includes a construction method of the protective layer, which specifically includes the following steps:

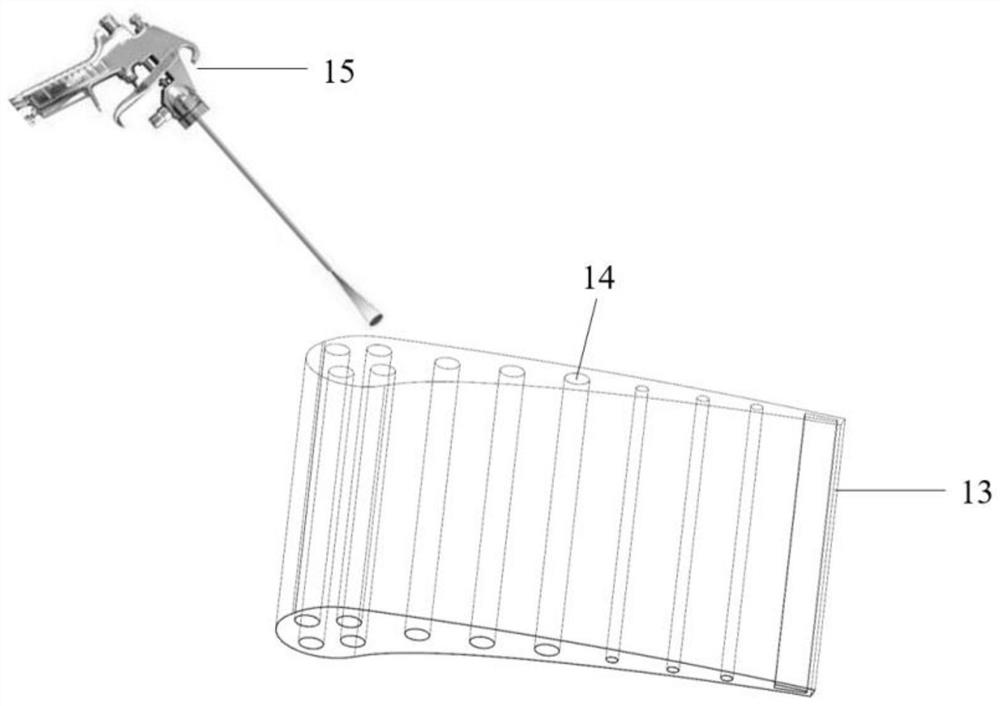

[0049] S51. Sandblasting or polishing the inner wall to be sprayed;

[0050] When processing the inner wall of the cooling channel 14 on the blade 13, the inner wall of the electromagnetic pump 4 through which the fluid flows, the inner wall of the expansion joint 6, the inner wall of the collector 12 that is in contact with the fluid, and the inner wall of the separator 1 that is in contact with the fluid. Carry out polishing treatment or sandblasting treatment to the inner wall according to the different selection of the structure of each component, so as to make the inner wall smooth;

[0051] S52, load the dry AlN ceramic powder into the inner wall spray gun 15 of the ultra-fine rod;

Embodiment 3

[0061] An anti-corrosion method for a liquid metal cooling blade system, comprising the liquid metal cooling blade system in Embodiment 1, and specifically comprising the following steps:

[0062] S71, according to the requirements of the design process, spray the blades 13, the electromagnetic pump 4, the expansion joint 6, the collector 12 and the separator 1 in the liquid metal cooling blade system;

[0063] Process the pipeline A2, pipeline B3, pipeline C5, pipeline D7, pipeline E9, pipeline F10 and pipeline G11 in the liquid metal cooling blade system according to the design requirements;

[0064] S72, assemble the separator 1, pipeline A2, pipeline B3, electromagnetic pump 4, pipeline C5, expansion joint 6, pipeline D7, heat exchanger 8, pipeline E9, pipeline F10, pipeline G11, collector 12 and vane 13, A liquid metal cooling blade system is obtained and liquid metal is injected into the liquid metal cooling blade system.

[0065] In an embodiment of the present inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com