Pulley device with embedded unidirectional clutch

A one-way clutch, built-in technology, applied in one-way clutches, clutches, hoisting devices, etc., can solve the problem of not being able to fully obtain the buffering effect of the torsion spring 18

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

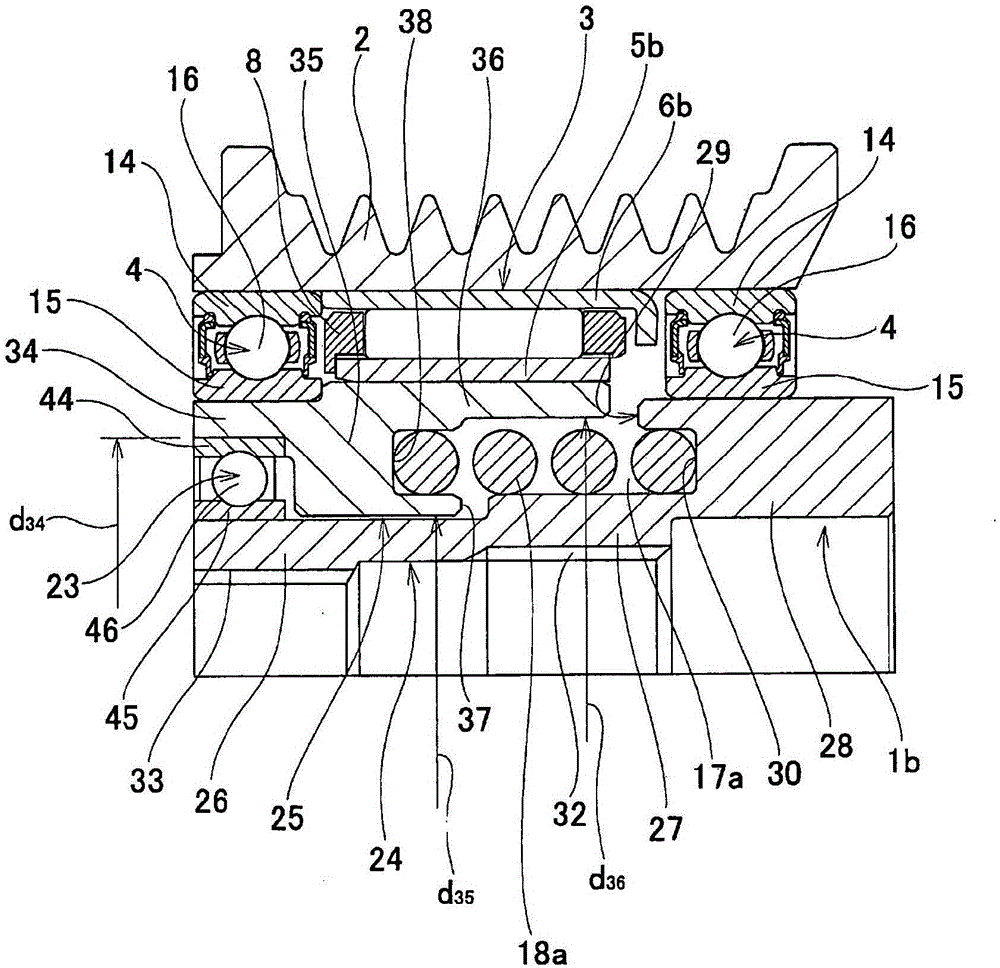

[0039] [1 example of embodiment]

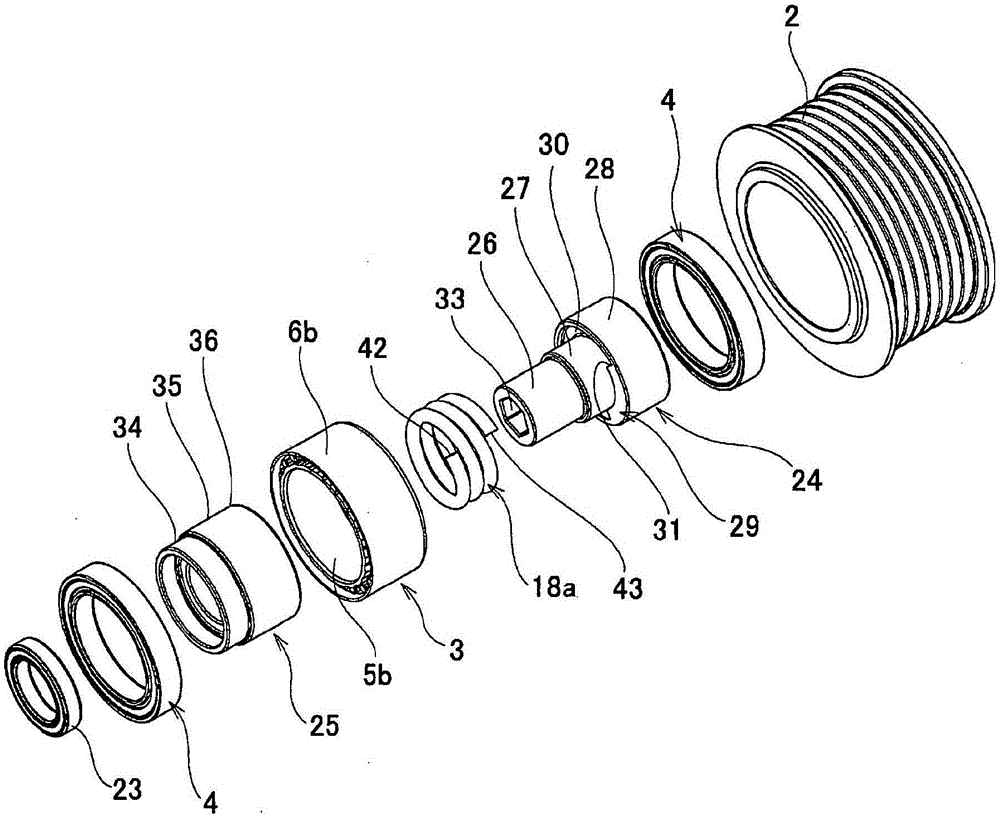

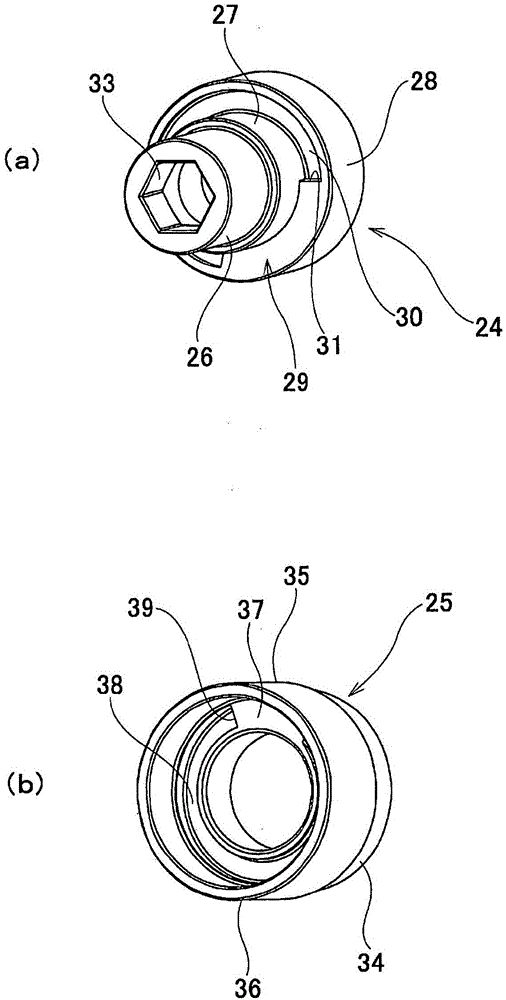

[0040] Figure 1 ~ Figure 3 One example of the embodiment of the present invention is shown. In addition, this example is characterized in that the structure of the sleeve 1b constituting the one-way clutch built-in pulley device and the assembly structure of the sleeve 1b are improved. The structure other than this characteristic part is substantially the same as that of the conventional pulley device with built-in one-way clutch. Therefore, the same reference numerals are assigned to the same parts as those in the conventional structure, and the following description will focus on the characteristic parts of this example.

[0041] The pulley device with a built-in one-way clutch of this example includes a sleeve 1b, a pulley 2, a one-way clutch 3, a torsion spring 18a corresponding to an elastic member, a pair of support bearings 4, and a ball bearing 23. The sleeve 1 b is a cylindrical member composed of a radially inner sleeve 24 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com