Polycondensation reactors in continuous or batch production plants for polyester production

A technology for a polycondensation reactor and a production device, applied in the field of polycondensation reactors, can solve the problems of high energy consumption, complex reactor structure and the like, and achieve the effects of simple operation, strong processing adaptability and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

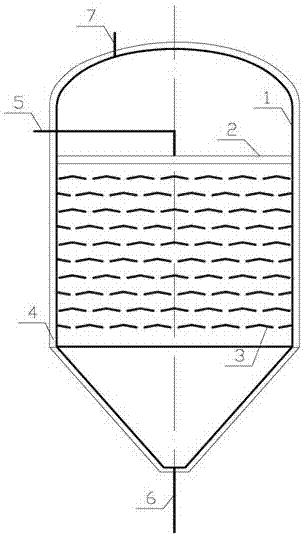

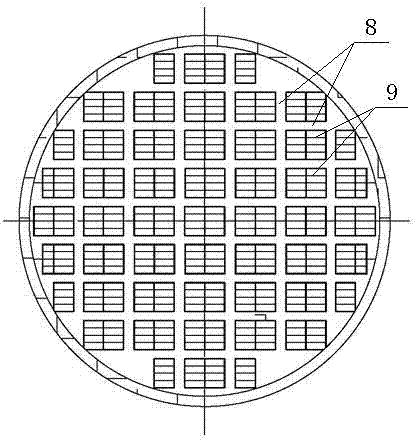

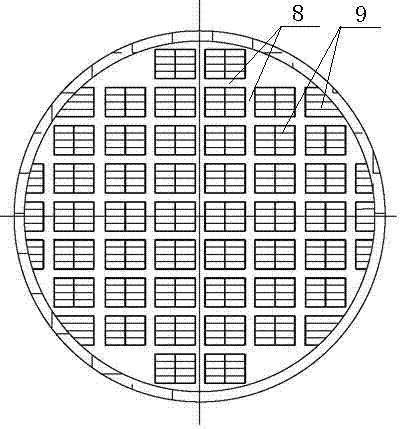

[0026] The present invention relates to a polycondensation reactor used in a continuous or batch production plant for polyester production, Figure 1 to Figure 5 It is shown as an embodiment, including a kettle body 1 , a jacket 4 , a material inlet pipe 5 , a liquid phase material outlet 6 and a gas phase material outlet 7 . The jacket is located outside the outer surface of the kettle body 1, the jacket is preferably a double-layer jacket, and the kettle body is provided with an inlet and an outlet of a heating medium communicated with the inner cavity of the jacket ( Not shown in the figure), through the inlet and outlet of the heating medium, the heating medium can be passed into the inner cavity of the jacket to increase the temperature in the kettle body and improve the heat transfer in the reactor. The inlet of the material inlet pipeline is located at the uppe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com