Dust suppression spraying device for railway coal transportation

A technology of spraying device and coal, applied in the direction of spraying device, liquid spraying device, etc., to achieve the effect of eliminating hazards to driving safety and efficient utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments, the purpose is only to understand the technical solution of the present invention more clearly, and the examples cited are not intended to limit the scope of protection of the present invention.

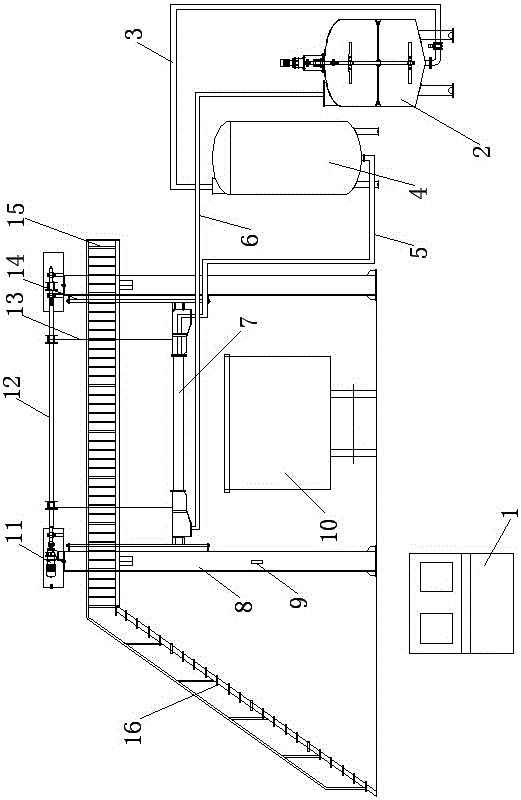

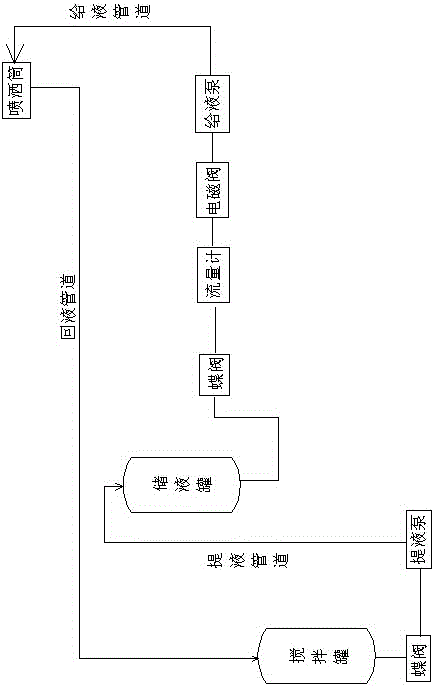

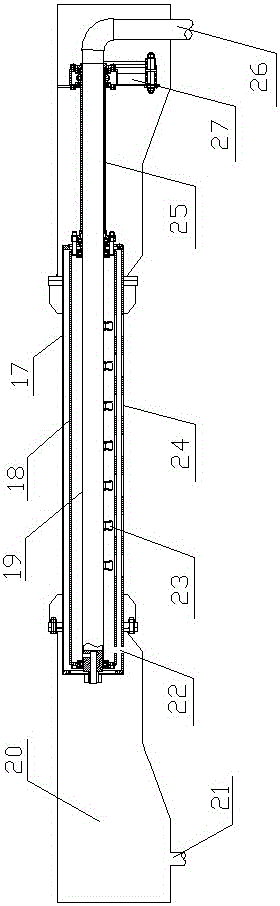

[0029] see Figure 1 to Figure 5 , a dust suppression spraying device for railway coal transportation, which consists of an operation table 1, a stirring tank 2, a liquid extraction pipeline 3, a liquid storage tank 4, a liquid supply pipeline 5, a liquid return pipeline 6, a spray cylinder 7, a column 8, and a photoelectric sensor switch 9. It is composed of maintenance platform 15, people ladder 16, blocking mechanism and lifting mechanism.

[0030] The console 1 is composed of a computer equipped with a Siemens PLC control system and a high-definition camera system, and has its own control buttons. The computer controls each part of the whole device. The c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com