A spline gear rubbing positioning tool

A technology for positioning tooling and splines, applied in the mechanical field, can solve problems such as phase angle not being detected in time, internal spline deformation, low pass rate, etc., to avoid repeated debugging, improve efficiency, and save time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

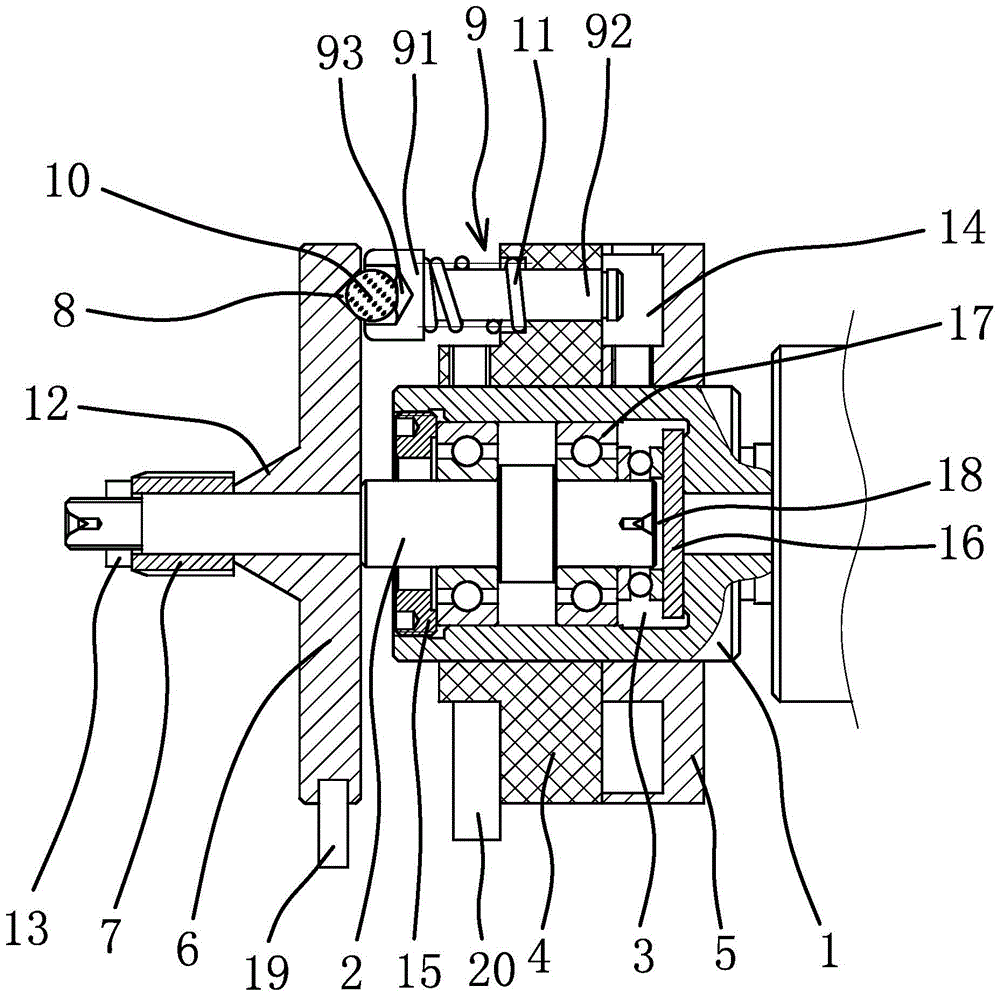

[0021] Such as figure 1 As shown, the spline gear rubbing positioning tool includes a connecting rod 1, a rotating shaft 2, an adjusting disc 4, a dial 5, a positioning disc 6, a spline mandrel 7, a positioning pin 9, a steel ball 10, a spring 11, and the like.

[0022] The front end of the connecting rod 1 has a cavity 3, the rear end is used to be fixedly connected with the workbench, and the outer wall of the front end of the connecting rod 1 is fixedly connected with an adjusting disc 4 and a dial 5 by welding. The rear end of the rotating shaft 2 is located in the cavity 3, and the circumferential outer wall of the rotating shaft 2 located in the cavity 3 has an annular protrusion. The opening of the cavity 3 is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com