Scraper chain assembling system and assembling technique thereof

A scraper chain and assembly system technology, applied in the direction of assembly machines, manufacturing tools, metal processing equipment, etc., can solve problems affecting the normal operation of scraper conveyors, coal shearers, unsatisfactory assembly accuracy of chain loading process, and labor of scraper chains. Intensity and other problems, to achieve the effect of high promotion value, simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

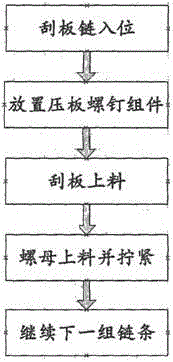

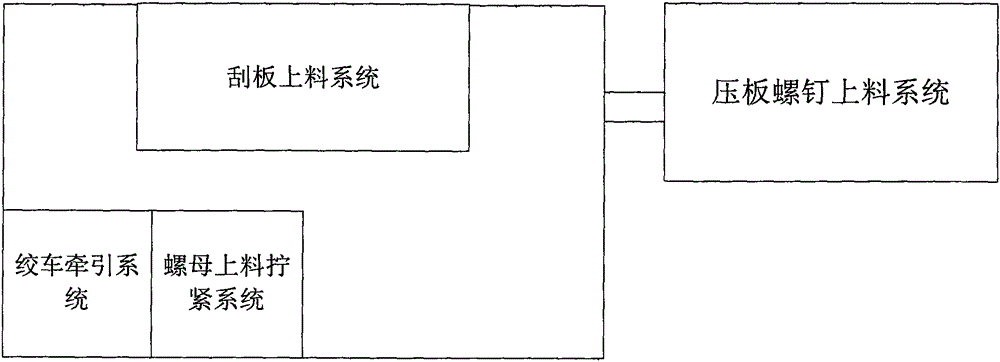

[0018] See attached figure 1 , which describes a preferred embodiment of the scraper chain assembly system according to the present invention. The scraper chain assembly system includes a movable car body platform. The car body platform includes a first car body platform and a second car body platform. Wheels or crawlers are respectively arranged under the two platforms, and are respectively arranged on driving devices such as motors. It can move under the drive of the driving device, and the two platforms are connected by hinges. The pressure plate screw feeding system, the scraper feeding system, the nut feeding and tightening system and the winch traction system are all arranged on the car body platform, preferably the pressure plate screw feeding system is arranged on the first car body platform, the scraper feeding system, The nut feeding and tightening system and the winch traction system are arranged on the second car body platform. The platen screw feeding system, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com