Vegetable cutter

A vegetable cutting machine and rack technology, applied in metal processing and other directions, can solve the problems of heavy vegetable cutting tasks, low production efficiency, large volume and other problems, and achieve the effects of low efficiency, simple structure and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

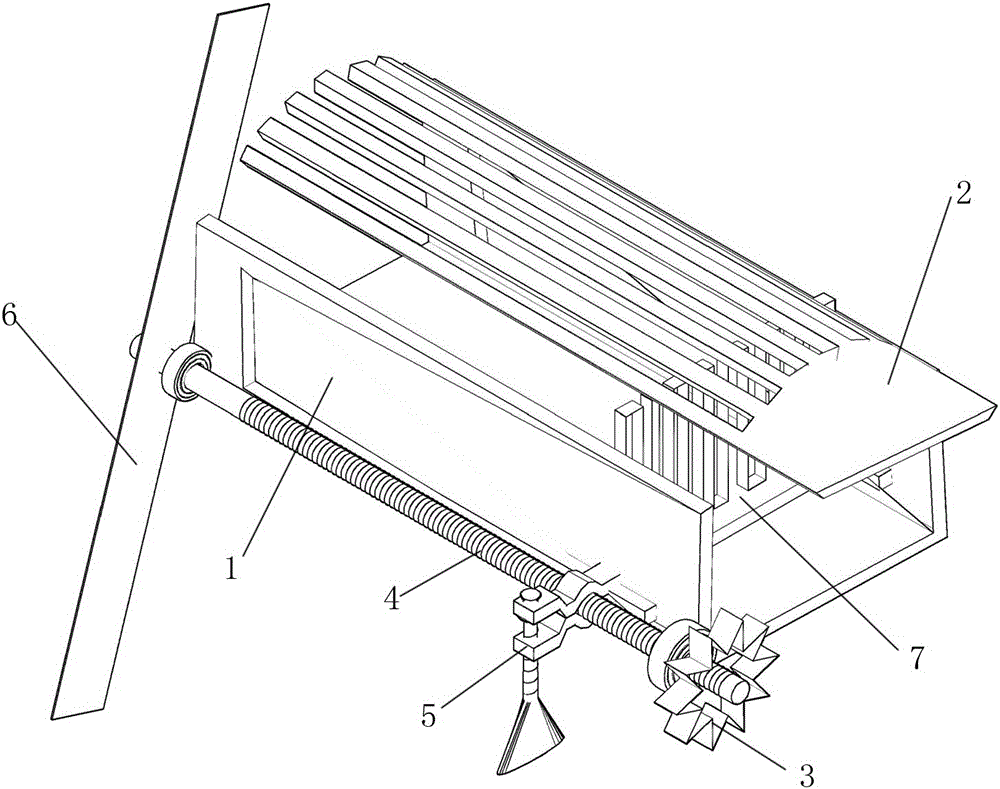

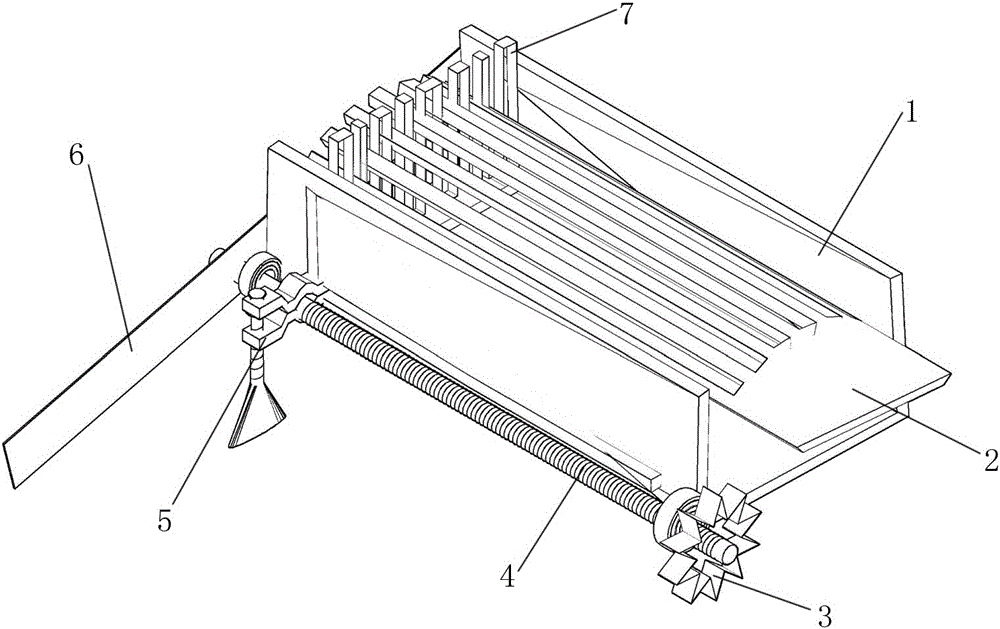

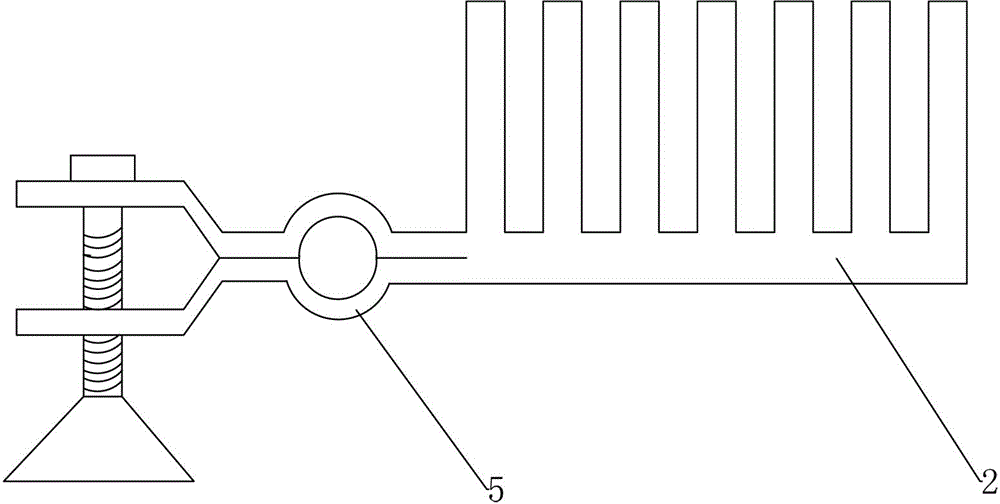

[0020] Such as Figure 1 ~ Figure 3 As shown, a vegetable cutting machine includes: a frame 1, a vegetable pressing plate 2 and a blade 6, the frame 1 is provided with a push plate 7, the push plate 7 is connected to the propulsion mechanism 5, and the propulsion mechanism 5 is closely connected to the transmission Rod 4, one end of transmission rod 4 is provided with at least one blade 6, the blade is movably arranged on the transmission rod 4, and the length or thickness of the cut vegetables is also controlled according to the number of blades, and the other end is connected with driving wheel 3, transmission rod 4 and propulsion mechanism 5 All are provided with threads. The end close to the blade on the transmission rod 4 is not provided with threads, and the threads on the propulsion mechanism 5 match the threads on the transmission rod 4 . At least three vertical bars are set on the push plate 7 . The described pressing board 2 is made up of at least three horizontal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com