An automatic feeding device for powder mixing machine

A technology of automatic feeding and powder mixing machine, used in the fields of pharmaceutical machinery and food packaging machinery, can solve the problems of environmental pollution, inability to achieve speed, etc., and achieve the effects of accurate positioning, saving workstations, and reducing complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

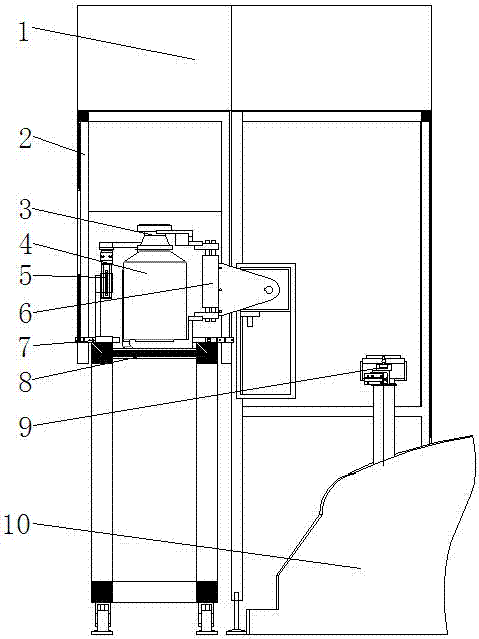

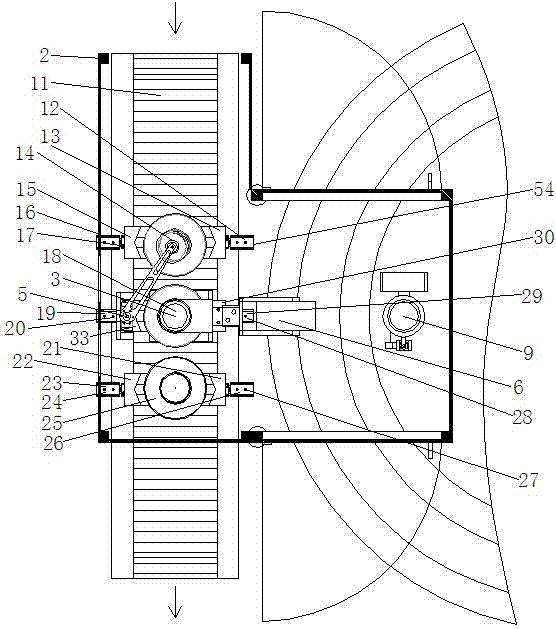

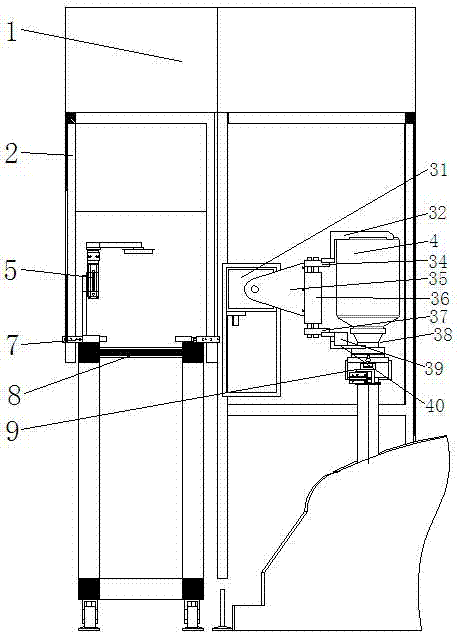

[0028] In order to clearly illustrate the technical characteristics of this solution, the following will describe this solution through specific implementation modes and in conjunction with the accompanying drawings.

[0029] An automatic feeding device for a powder mixer, as shown in the figure, it includes a frame 2 with a conveying channel 11, and the conveying channel 11 includes multiple groups of conveying rollers 8 installed in parallel on the frame 2, the A laminar flow hood 1 is arranged on the top of the frame 2, and the cover opening station 14, the turning station 18 and the cover drop station 25 are successively arranged on the frame 2 along the advancing direction of the conveying channel 11, and the frame 2 Positioning and clamping devices 7 are respectively arranged on the two sides corresponding to the uncapping station 14, the flipping station 18 and the cap-dropping station 25. The cover station 25 is equipped with a pick-and-place cover device 5 for the raw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com