Oil slurry filtration system

A filtration system and oil slurry technology, applied in the direction of filtration and separation, refining by filtration, fixed filter element, etc., can solve the problems of complicated control, prolonged time, shortened system operation period, etc., to achieve stable system operation and maintain stability The effect of sex, operation simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

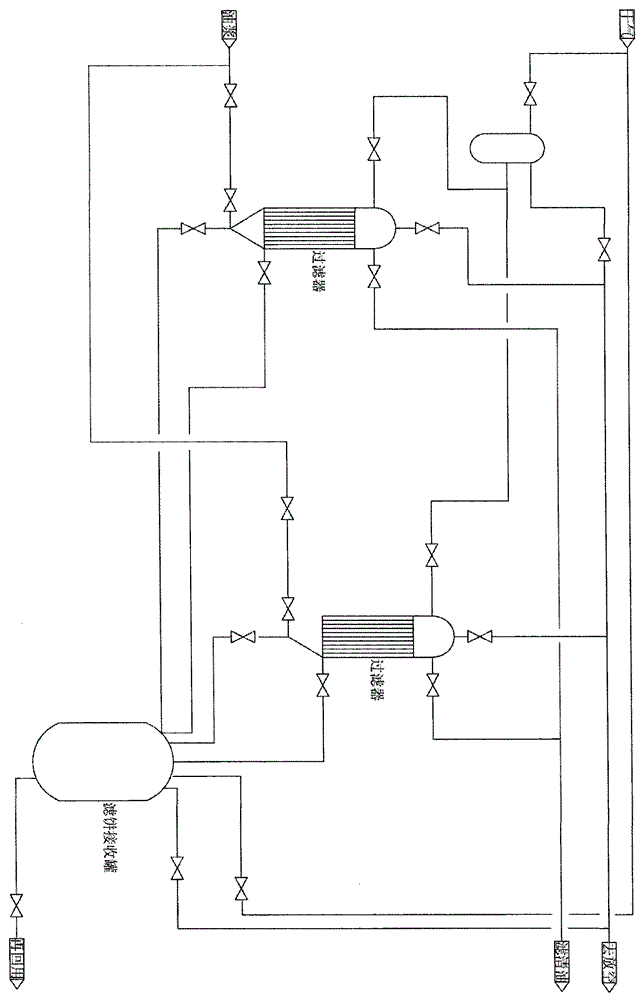

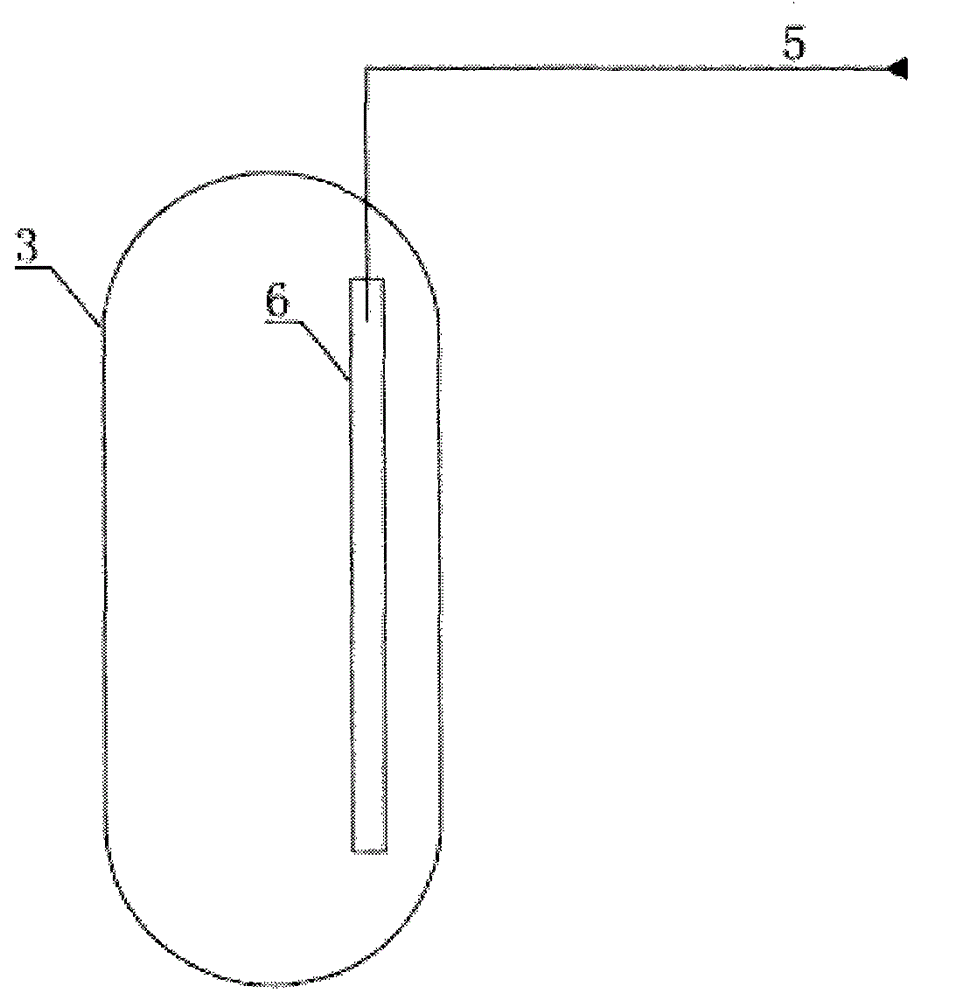

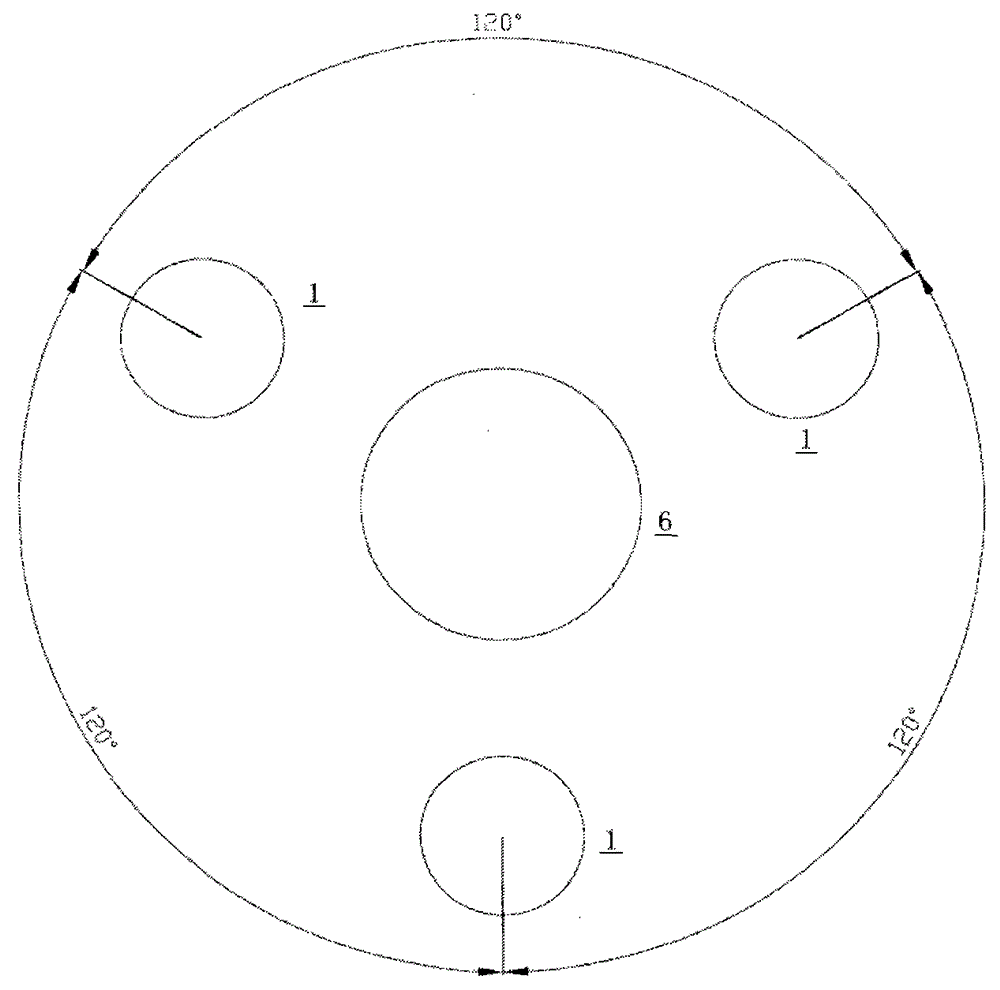

[0056] Such as Figure 5 As shown, the oil slurry filtration system of the present invention includes: three filters 1, soaking liquid buffer tank 2, discharge buffer tank 3 and filter cake receiving buffer tank 4;

[0057] Wherein, the three filters 1 are respectively provided with oil slurry inlet pipelines, so that the oil slurry can enter the three filters respectively, and the tops of the three filters 1 are respectively provided with pipelines directly connected to the discharge pipes. The pipeline connected to the buffer tank, so that the discharge filtered by the three filters can enter the discharge buffer tank 3;

[0058] The discharge buffer tank 3 is used to receive the discharge filtered by the three filters;

[0059] The soaking liquid buffer tank 2 is provided with a pipeline directly connected to the three filters, so that the filter not in the filtering state is soaked, and the soaking liquid buffer tank is also provided with a pipe connected to the discharge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com