Application method of robot in surface treatment production

A surface treatment and application method technology, applied in the direction of manipulator, anodic oxidation, electrolysis process, etc., can solve the problems of many auxiliary mechanisms, insufficient manpower, slow running speed, etc., and achieve fast response speed, diversified actions, and shortened cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solution in the embodiment will be specifically, clearly and completely described below in conjunction with the drawings in the embodiment.

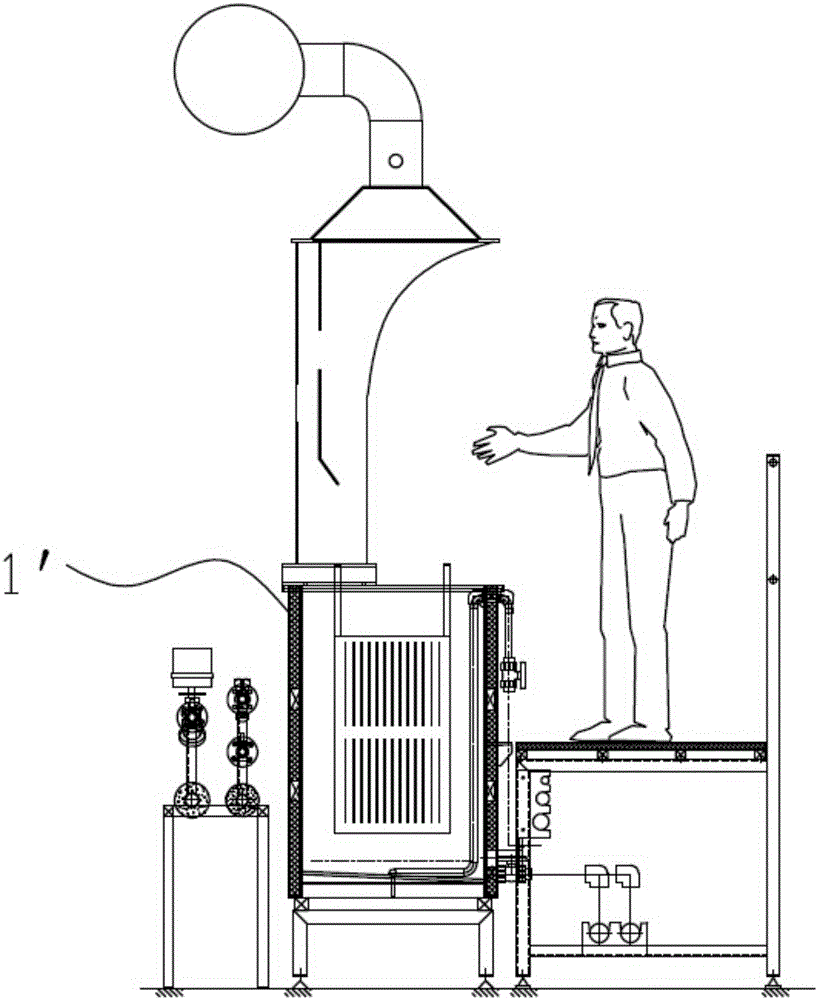

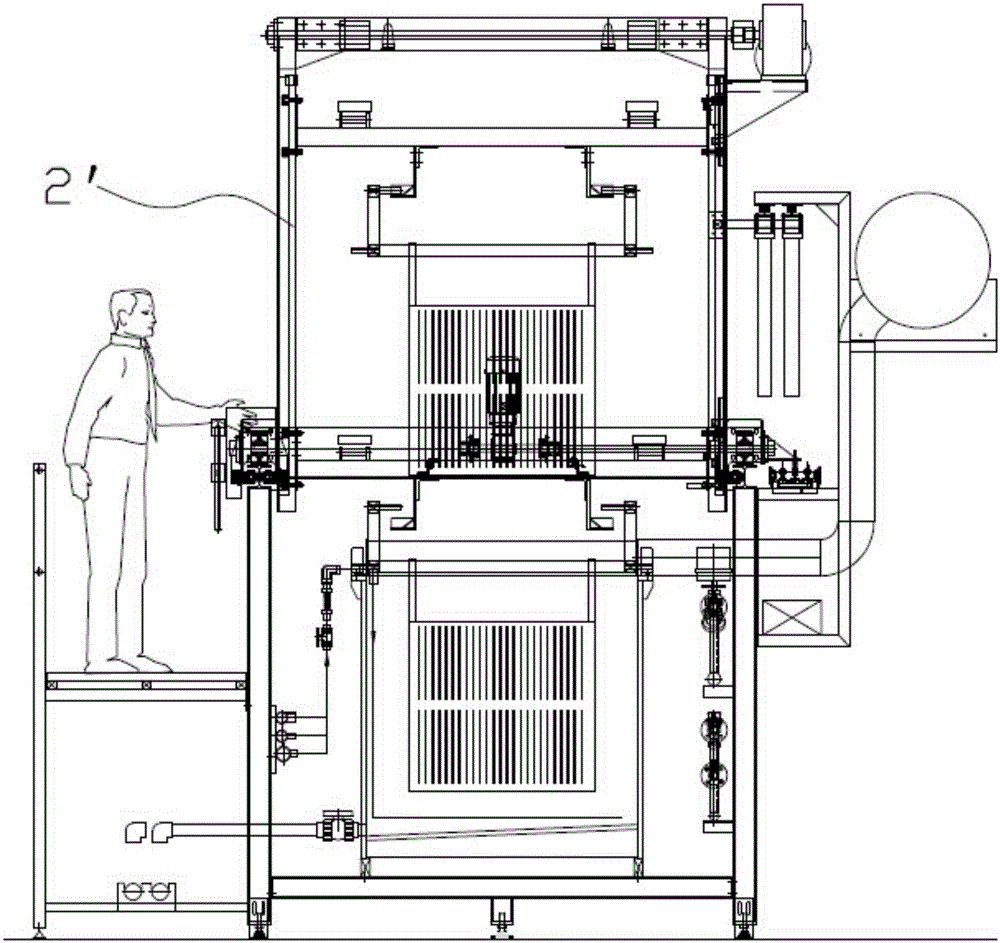

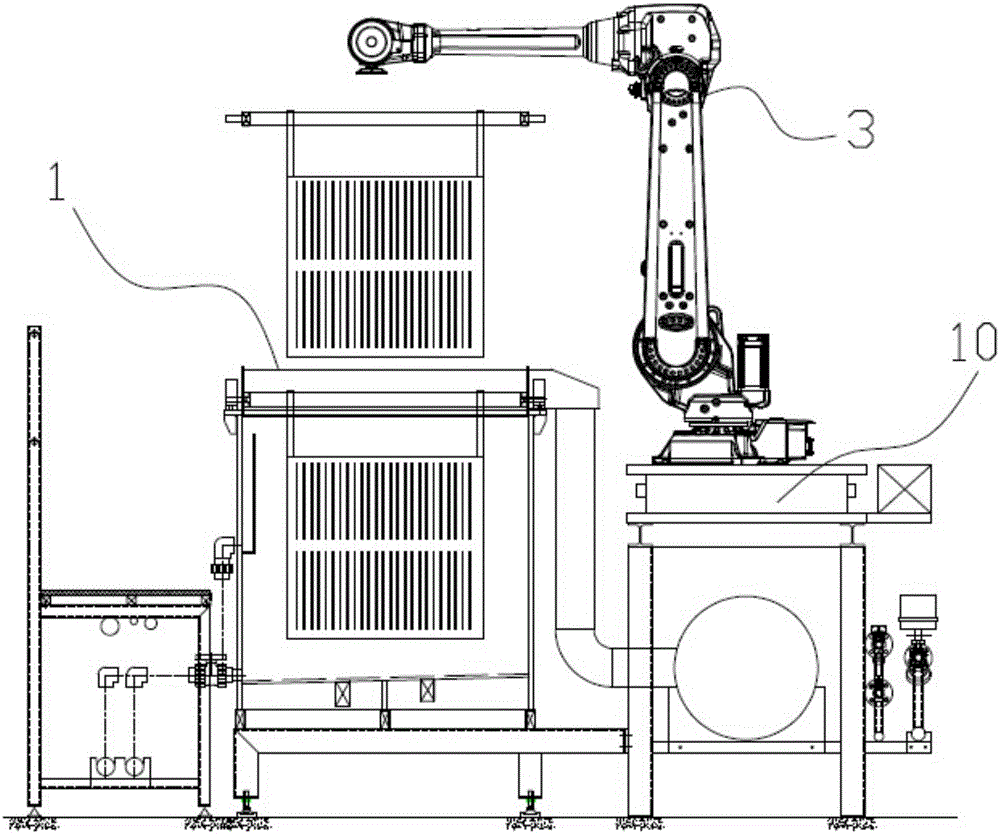

[0035] see image 3 Shown is a schematic diagram of the application state of the robot of the present invention in surface treatment production. The method comprises the steps of:

[0036] A movable robot 3 and its control system are provided. The robot 3 is placed on the robot track 10 of the surface treatment equipment 1. Through the control system, the robot 3 is controlled to perform various actions of the plated parts in each process. Specifically, the actions to be performed by the robot include lifting, walking, tilting, rotating, swinging and automatic opening and closing of the drum cover.

[0037] The invention uses robots to replace workers in manual equipment for handling, can complete various manual actions, solves the problem of worker fatigue and the physical injury caused by harsh environments to wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com