Thermal insulation fireproof steel-wood door

A fireproof door and wood technology, applied in the field of fireproof doors, can solve the problems of poor strength of fireproof doors, easy deformation of door leaves, failure to achieve fireproof performance, etc., so as to improve strength and impact resistance, improve sealing and fireproofing effect, and improve fireproofing effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings.

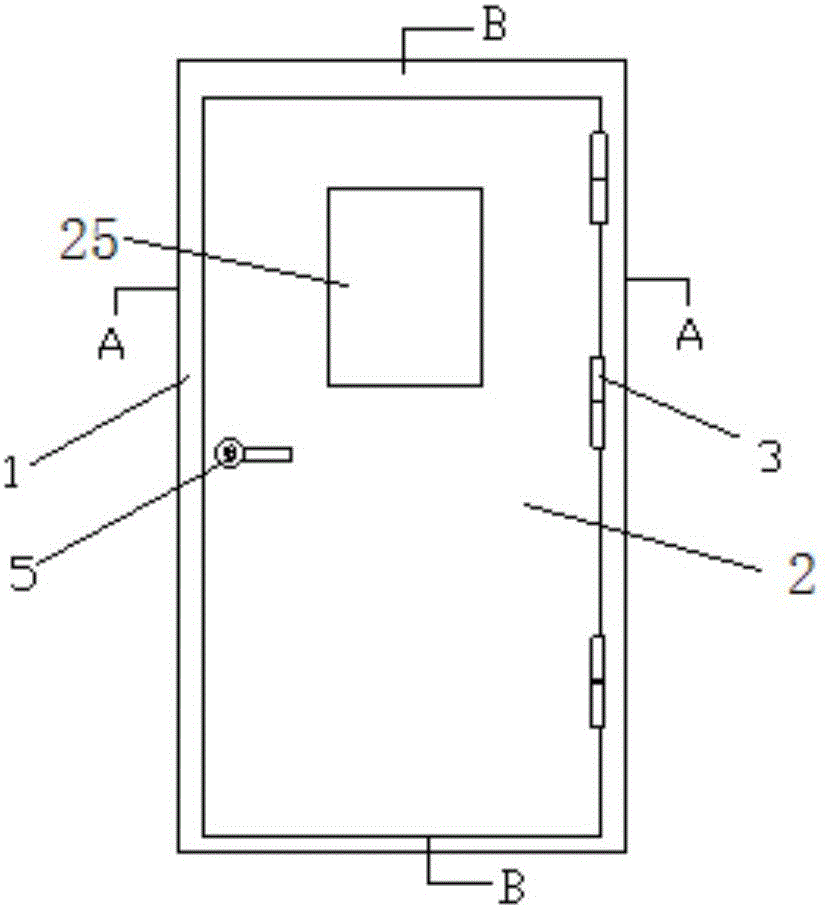

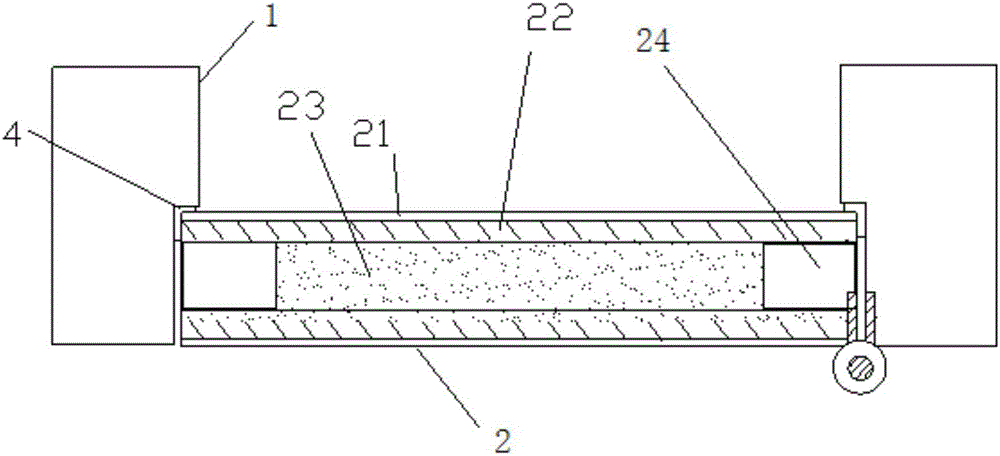

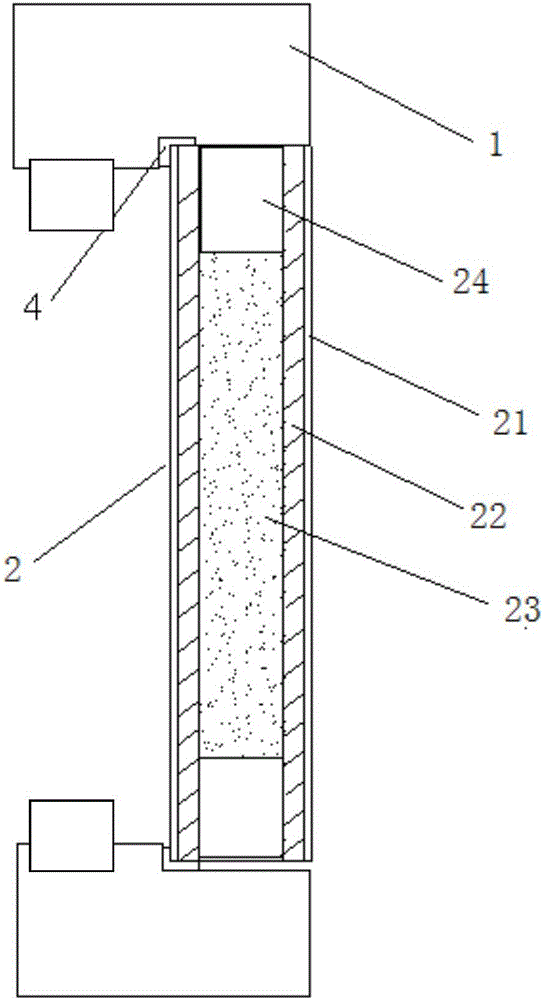

[0022] Such as Figure 1-3 As shown, this embodiment discloses a steel-wood heat-insulated fireproof door, comprising a door frame 1 and a door leaf 2, and the door frame 1 is hinged with the door leaf 2 through a fireproof hinge 3; It is L-shaped, and the door leaf 2 is limited by the L-shaped door frame 2 in the closed state. The door leaf 2 is sequentially provided with plywood 21 , glass magnesium plate 22 , and expanded perlite fireproof board 23 from outside to inside in the thickness direction. The plane size of the expanded perlite fireproof board 23 is smaller than the plane size of the plywood 21 and the glass magnesium flat board 22 . Fire-resistant wood 24 is provided around the expanded perlite fireproof board 23 . There is an L-shaped fireproof expansion seal 4 between the door frame 1 and the door leaf 2. The L-shaped fireproof expansion seal 4 is i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com