Automatic compensation type gapless well mouth sealing device

A technology of automatic compensation and sealing device, which is applied in sealing/isolation, wellbore/well parts, earthwork drilling and production, etc., to achieve good sealing performance, ensure continuous normal and safe production, and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to have a clearer understanding of the technical features, objects and effects of the present invention, the present invention will now be described with reference to the accompanying drawings.

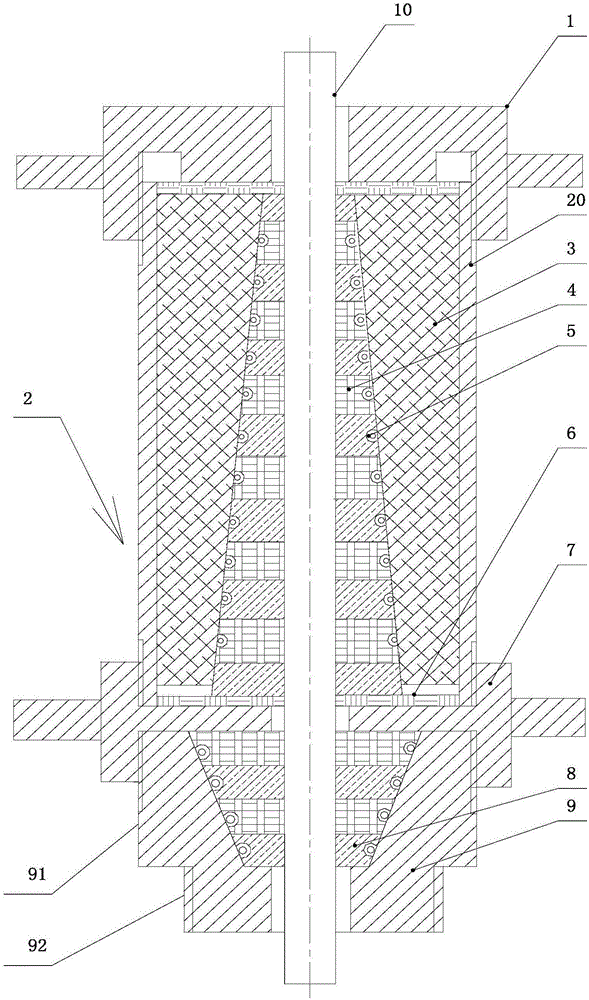

[0025] like figure 1 As shown, the automatic compensation type gapless wellhead sealing device according to the embodiment of the present invention is used to seal the sucker rod 10, and the automatic compensation type gapless wellhead sealing device includes:

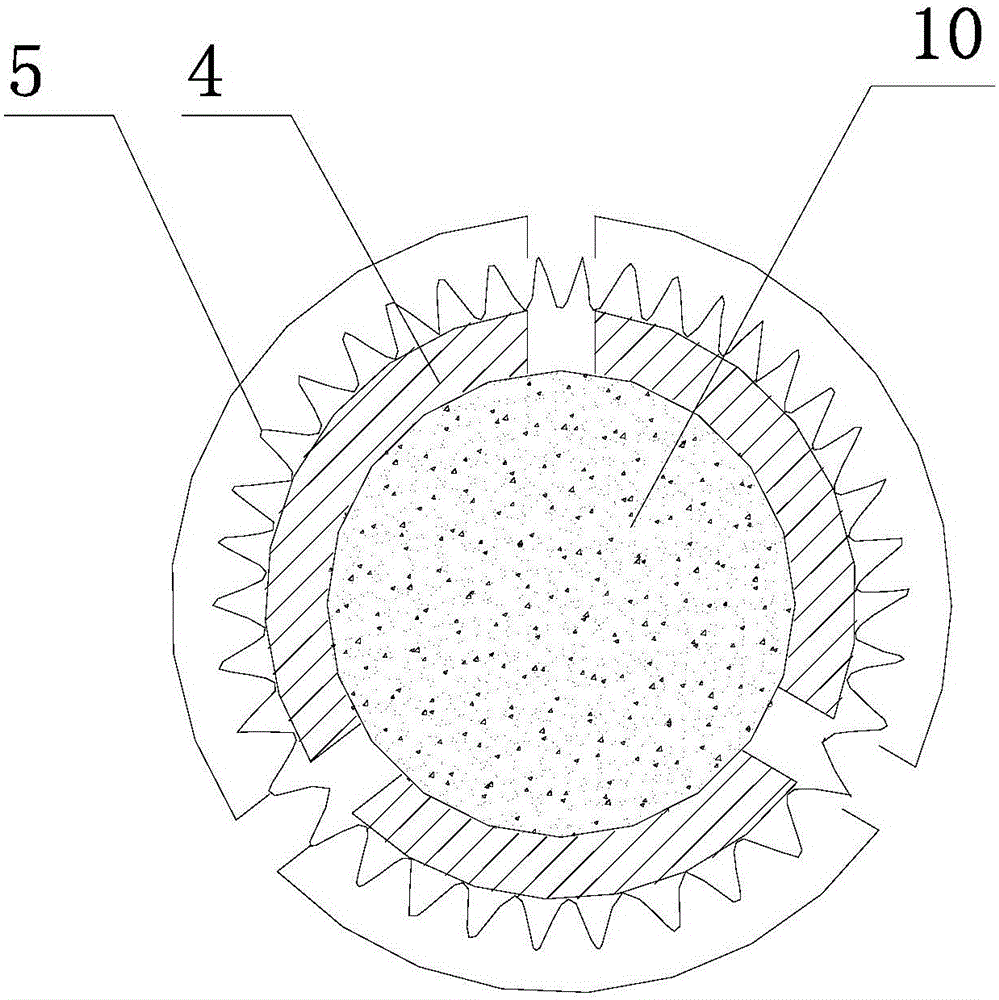

[0026] A plurality of first split-type seal rings 4 are layered from top to bottom to form a truncated cone or a tower-shaped sleeve on the sucker rod 10, and each first split-type seal ring is sleeved with a the first tightening spring 5, wherein the diameter of the lower first split-type sealing ring is larger than the diameter of the upper first split-type sealing ring;

[0027] The primary sealing box 2 has a conical inner side wall, and the inner side wall of the primary sealing box is consistent with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com