Self-sufficient type internal combustion engine gas fuel supply system and gas packet pressure control method

A gas fuel and supply system technology, applied in the direction of fuel injection control, charging system, electrical control, etc., can solve the problems of large mutual influence of the system, unfavorable long-term safety of the system, high-efficiency operation, and prone to failure, etc., to achieve vacuum fluctuations small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with embodiment the present invention will be further described.

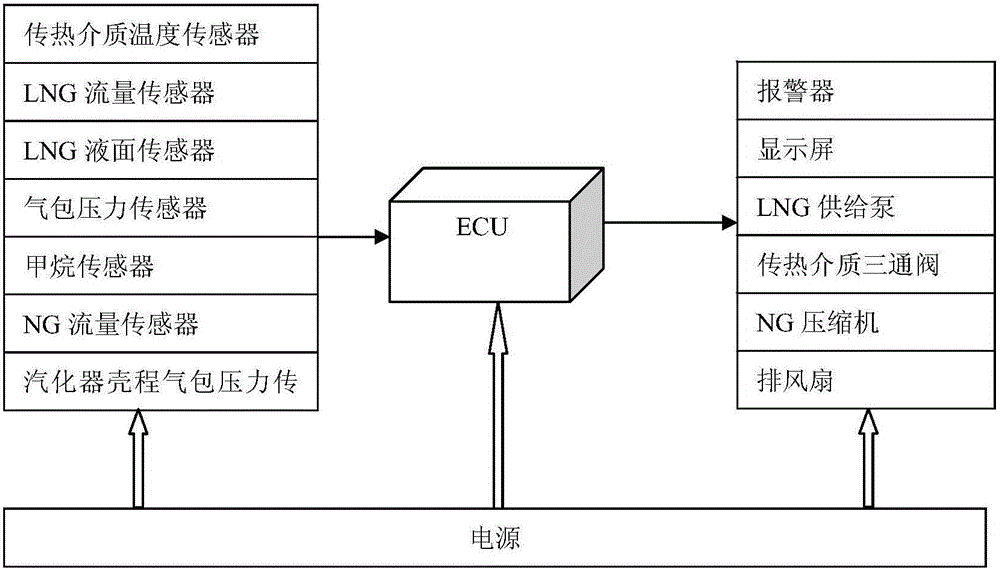

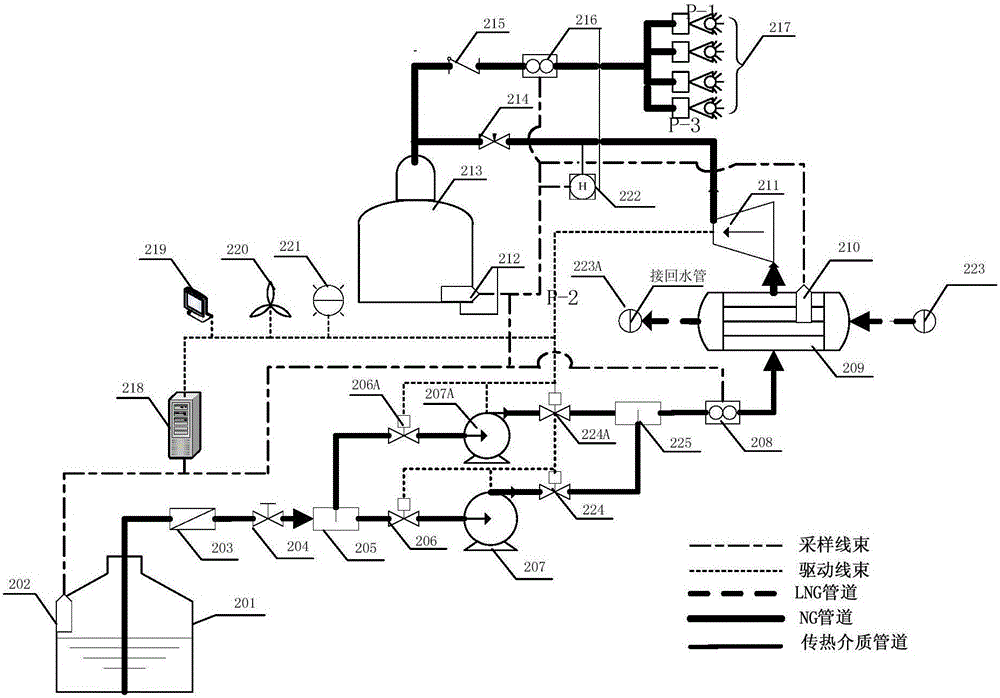

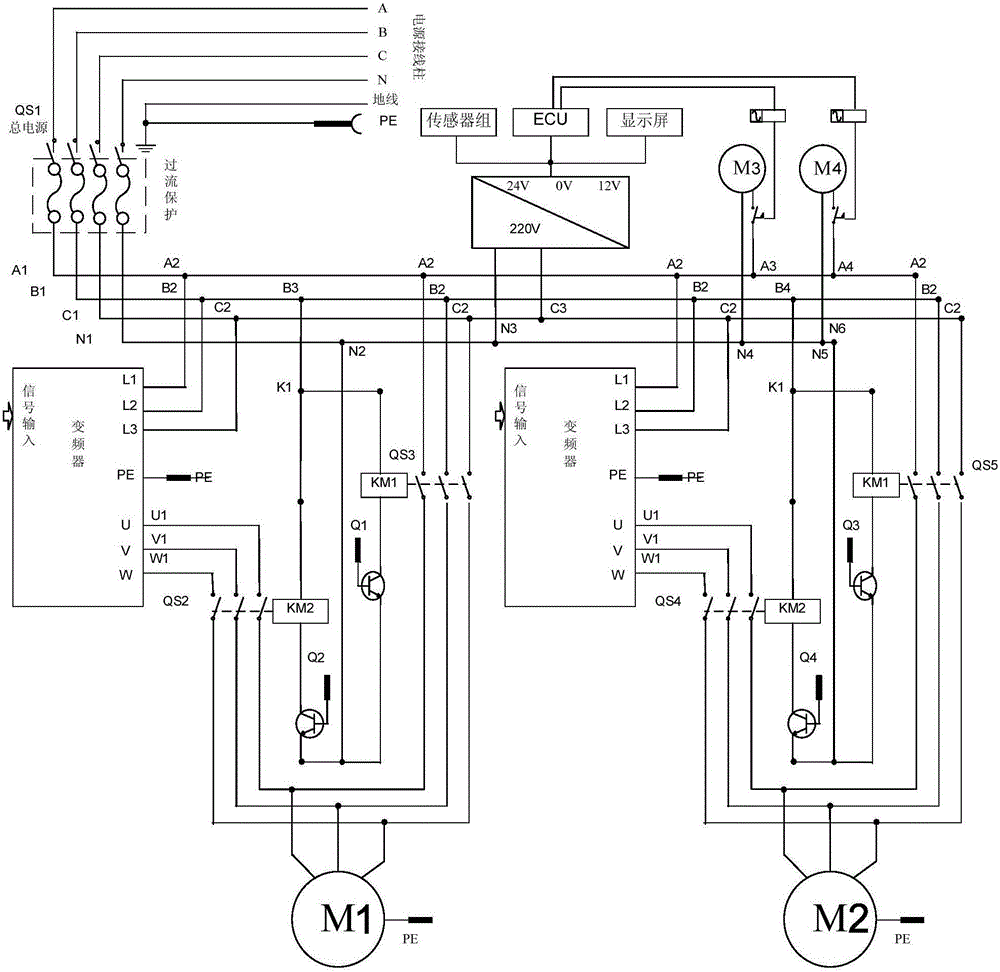

[0035] like Figure 1 to Figure 6 As shown, a self-contained internal combustion engine gas fuel supply system includes LNG tank 201, LNG supply pump 207, LNG vaporizer 209, NG compressor 211, gas bag 213 and NG injection valve 217, between the LNG tank and the LNG vaporizer The LNG delivery section is connected in turn with LNG filter 203, manual valve 204, front three-way 205, front solenoid valve 206, LNG supply pump 207, rear solenoid valve 224, rear three-way 225 and LNG flow sensor 208, front three-way 205 Two pipelines are used between the rear three-way 225, the front three-way one is connected to the front solenoid valve 206, the LNG supply pump 207, the rear solenoid valve 224 and one interface of the rear three-way 225, and the other front three-way is connected to the spare pipeline The front solenoid valve 206A, the backup pipeline LNG supply pump 207A, the backup pipel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com