Piston pumps, especially fuel pumps for fuel systems of internal combustion engines

A technology of piston pumps and pistons, which is applied in the direction of charging systems, fuel injection pumps, components of pumping devices for elastic fluids, etc., can solve the problems of strong heating of piston pumps, adverse effects on piston pump performance and durability, etc. Achieve the effect of reducing wear, reducing piston ulceration and reducing vapor bubble formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

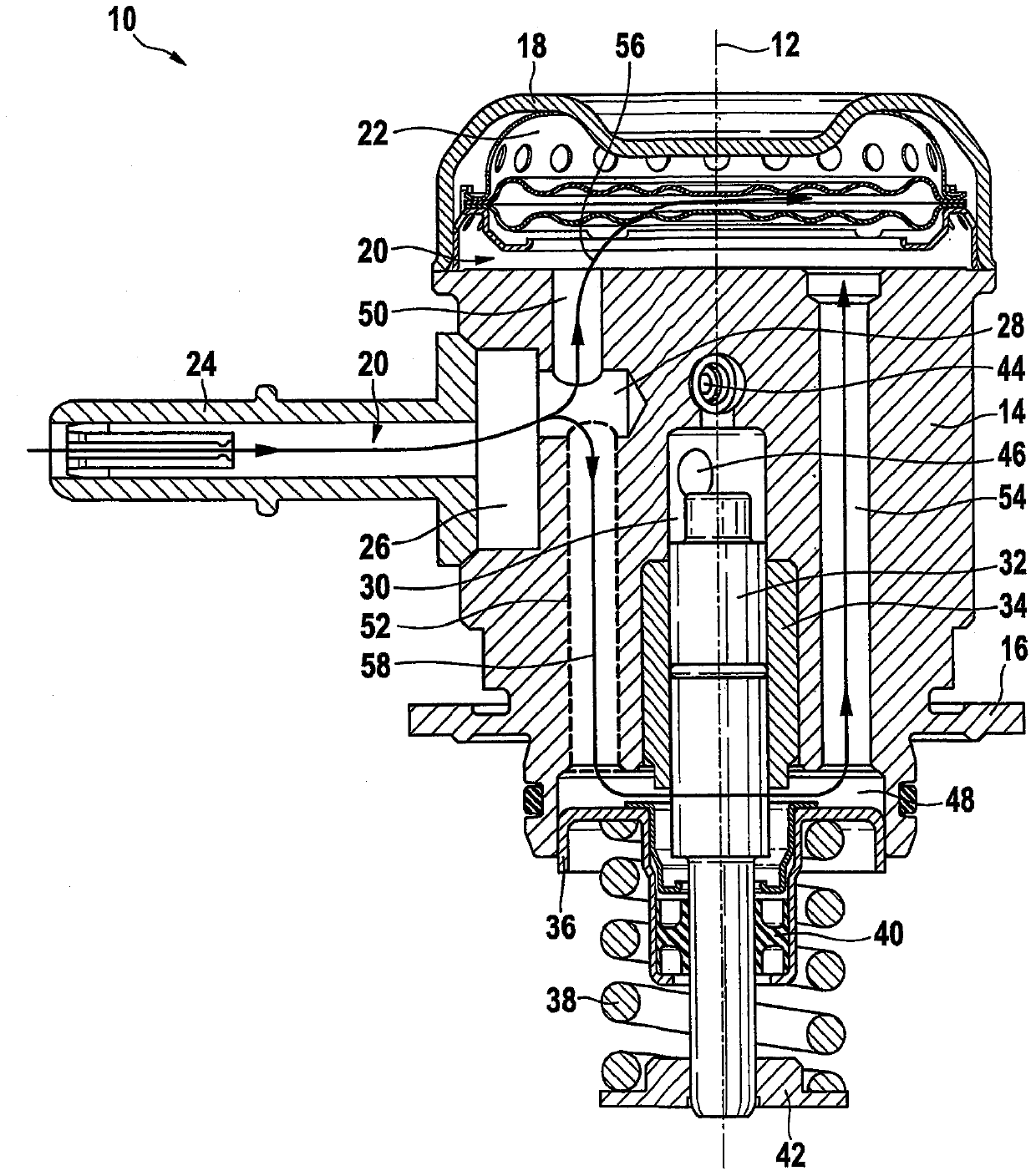

[0015] figure 1 A high-pressure fuel pump, presently embodied as a piston pump 10 , is shown in axial section. The piston pump 10 is an element of a fuel system (not shown), for example a common rail fuel system for an internal combustion engine, also not shown. Piston pump 10 is at least partially rotationally symmetrical about longitudinal axis 12 .

[0016] The piston pump 10 comprises a substantially cylindrical housing 14 which, by means of a flange 16 , can be screwed to a not shown engine block of an internal combustion engine. The piston pump 10 in figure 1 In the upper region, there is a chamber-shaped inlet-side low-pressure zone 20 formed between the arched cover 18 and the upper, substantially flat end face of the housing 14 in the figure, in which a low-pressure zone for A pressure damper 22 damps the pressure fluctuations that occur during the operation of the above-mentioned piston pump 10 .

[0017] Piston pump 10 has an inlet connection 24 in the region on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com