Hydrostatic piston machine

A technology of piston machine and axial piston machine, which is applied in the field of piston machine, can solve the problems of incompleteness and interruption of suction, and achieve the effect of long service life and increased suction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

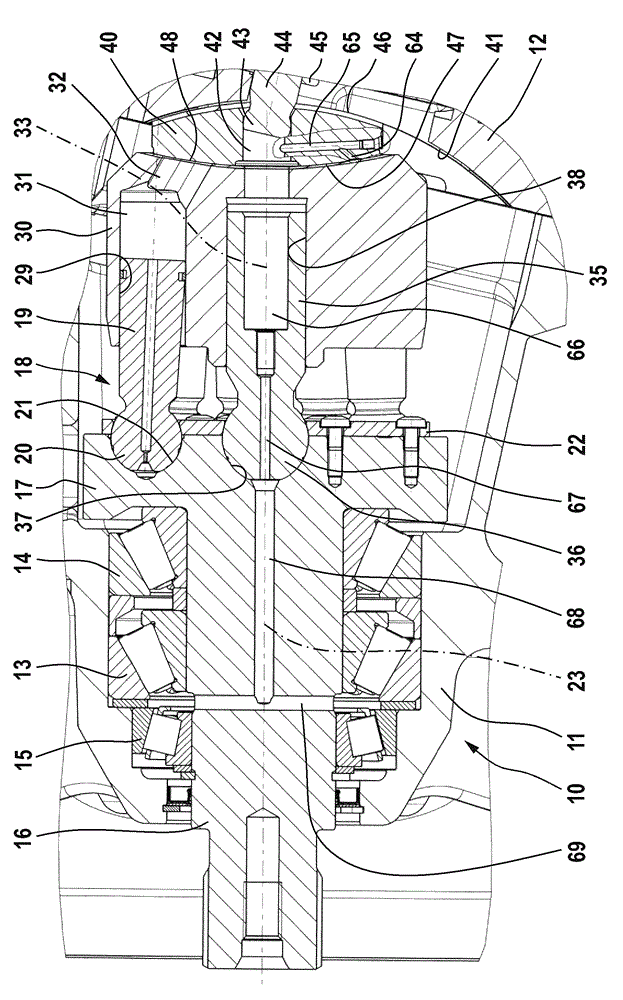

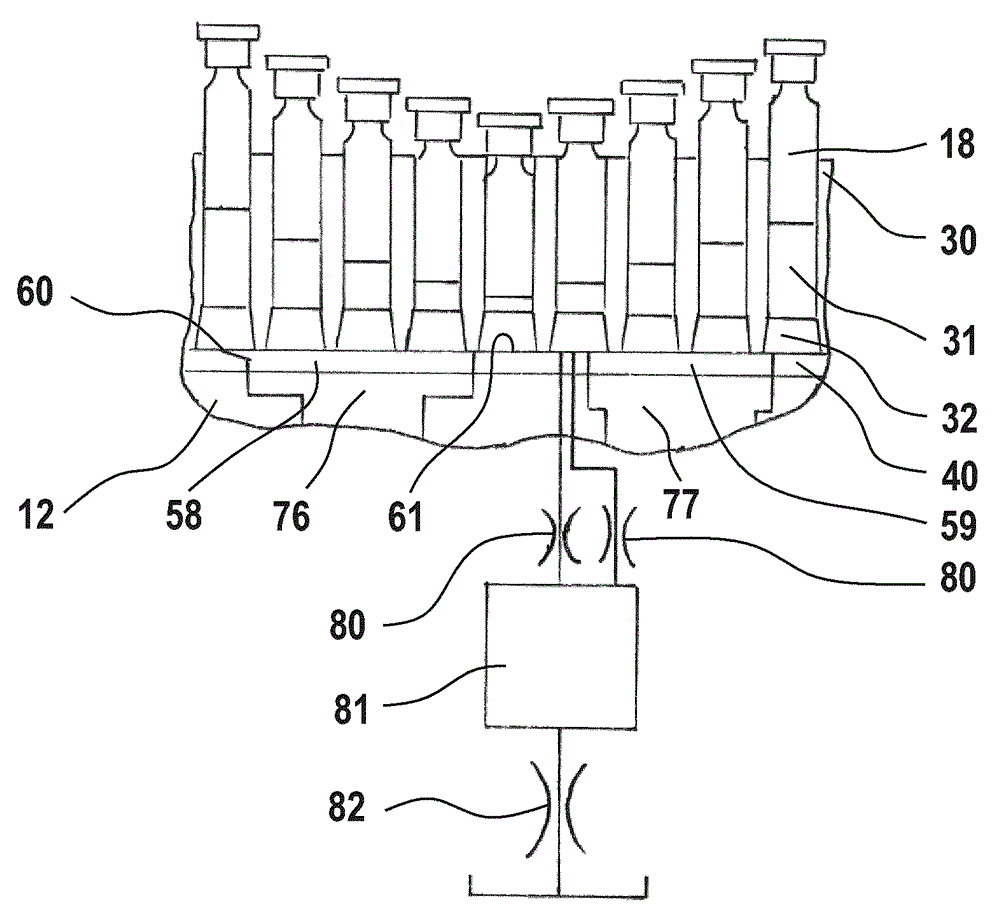

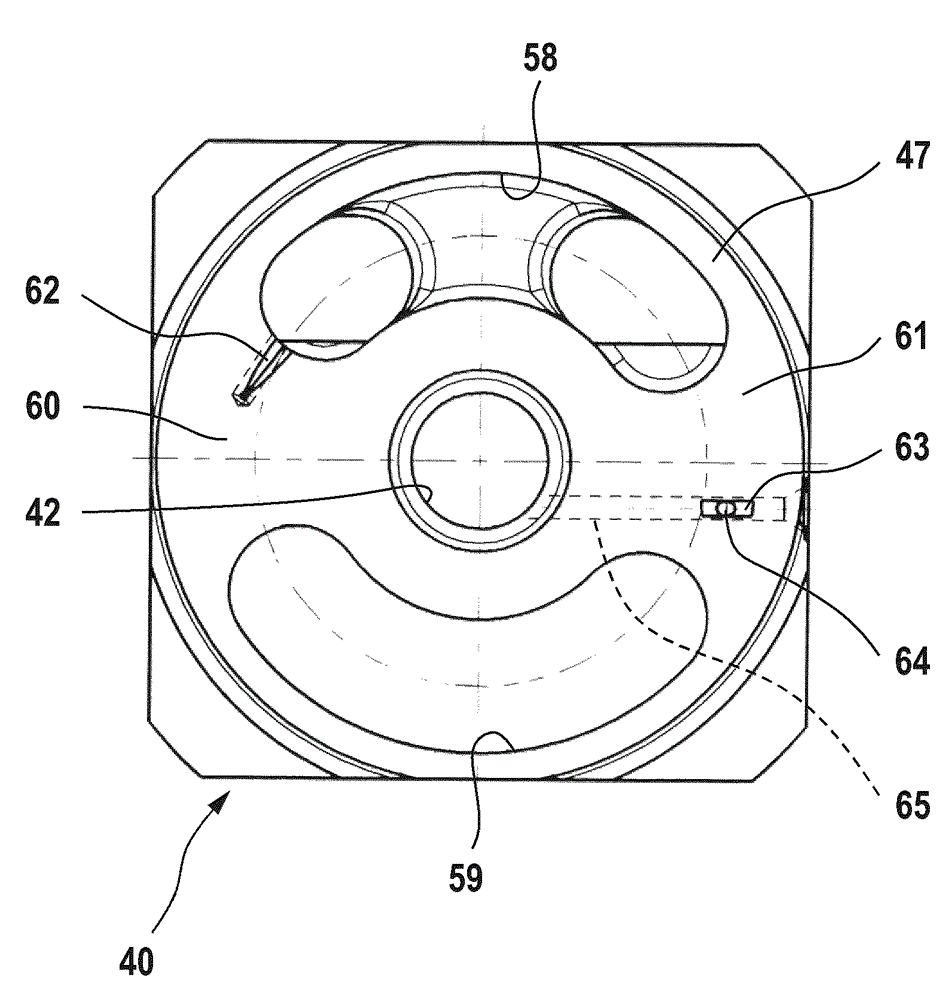

[0037] exist Figures 1 to 3 The hydrostatic axial piston machine shown in detail in the oblique-axis construction is firstly provided for pump operation with hydraulic oil and has a pot-shaped main housing part 11 for short and a cover housing tank connection The housing 10 of the plate 12 on which the high-pressure connection and the low-pressure, suction or tank connection are formed and at the same time the housing for the adjustment mechanism is shown. In the housing pot 11 , a drive shaft 16 is rotatably mounted via three tapered roller bearings 13 , 14 and 15 , which carries a drive flange 17 in one piece. The bearing function is essentially fulfilled by two identical tapered roller bearings 13 and 14 arranged parallel to one another. The smaller tapered roller bearing 15 , which is arranged as a mirror image with respect to the two bearings 13 and 14 , is used for counter-guiding the drive shaft.

[0038] On the drive flange 17 , the piston 18 is supported and held v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com