pump housing

A pump casing, centrifugal pump technology, applied in the direction of pumps, pump components, non-variable pumps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

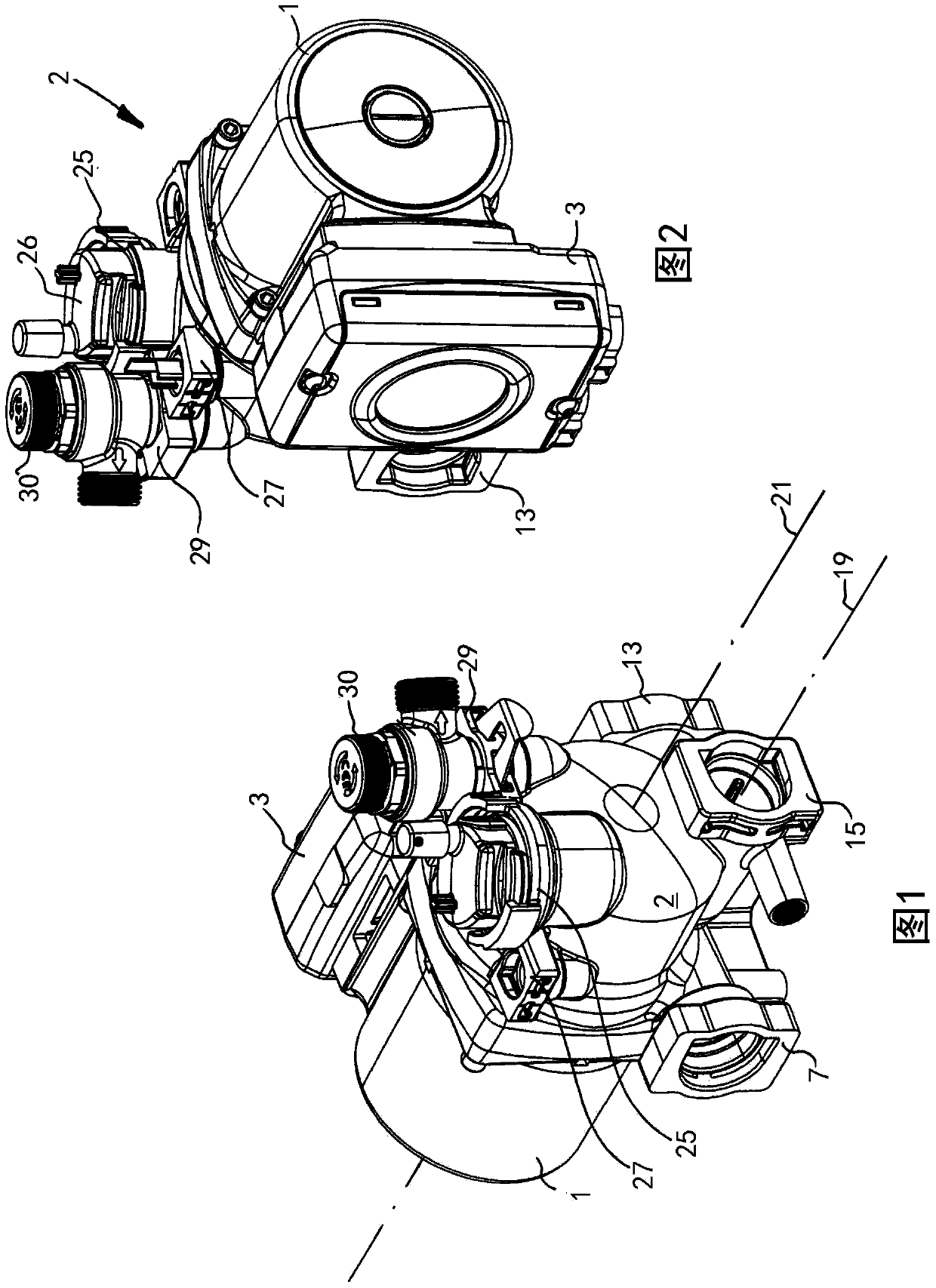

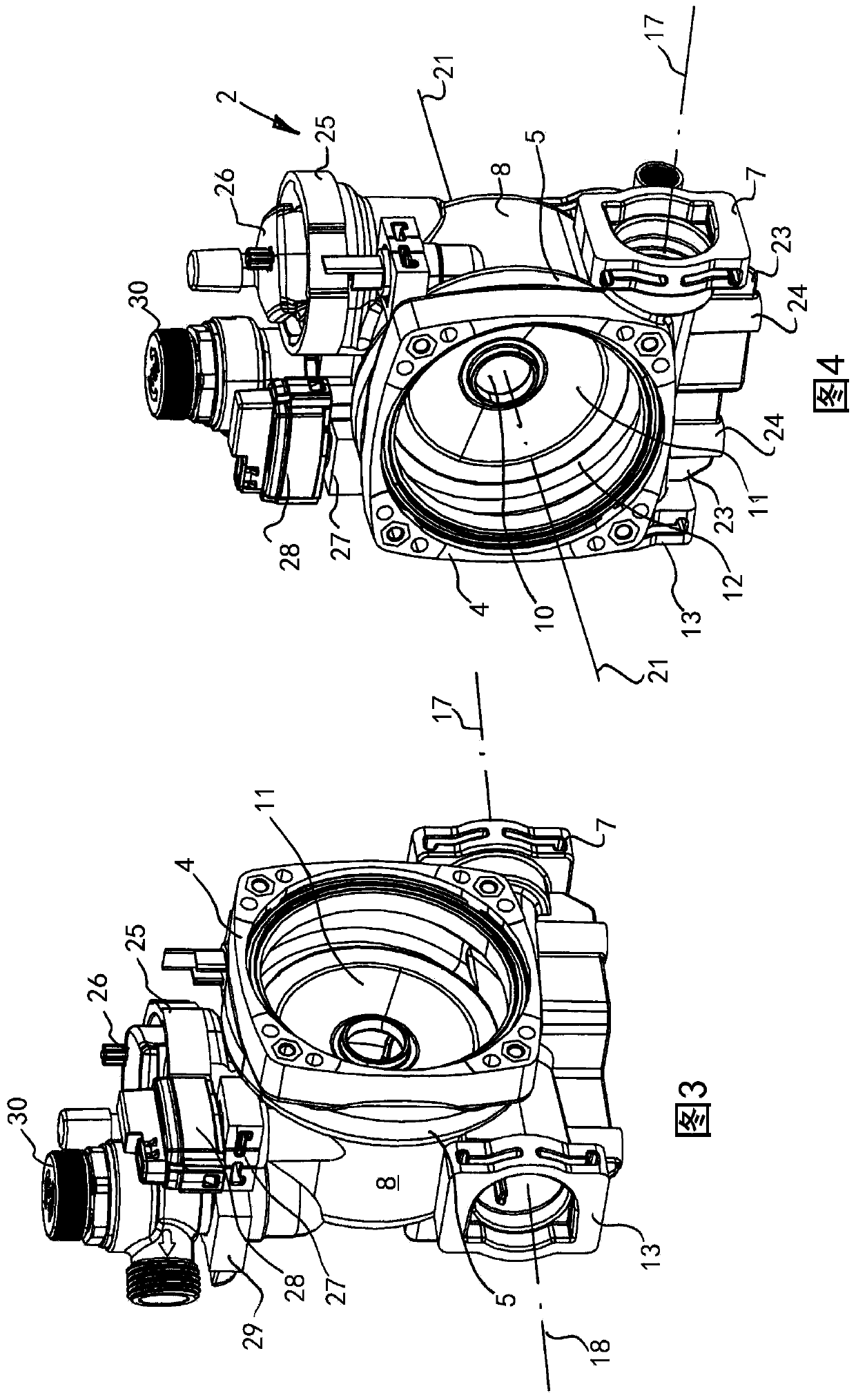

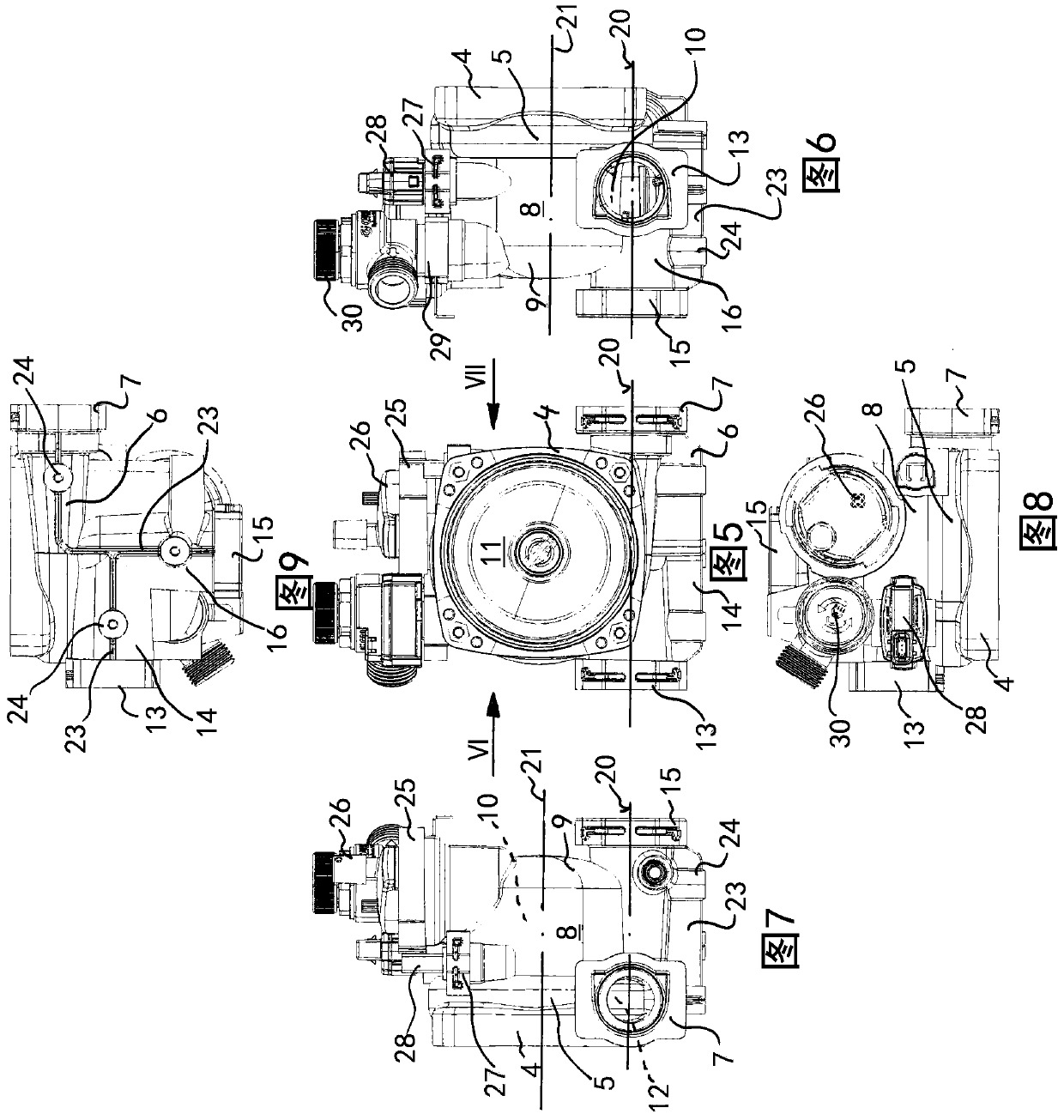

[0065] The heating circulation pump assembly shown in the figure comprises an electric motor 1 ; the electric motor 1 is designed as a wet-running motor, ie comprises a container 32 in which a rotor with a shaft is rotatably mounted. The interior of the container 32 is filled with fluid and said shaft is anchored in the rotor of the motor 1, the free end of which shaft carries a pump impeller 31 which is arranged in the pump housing 2 which is flanged Installed on the driving motor 1, the centrifugal pump assembly shares the driving motor 1. A terminal box 3 is arranged laterally on the drive motor 1, via which not only the coils provided in the stator are connected and connected to the power supply, but also a frequency converter, by means of which the motor 1 can be effectively speed control.

[0066] The pump housing 2 has a substantially beaker-like shape. It comprises a flange 4 designed to be connected to an opposing flange correspondingly designed to the drive motor. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com