Water storage type heat-dissipation anti-coking structure of biomass burner

A burner, biomass technology, applied in combustion chambers, combustion methods, combustion equipment and other directions, can solve the problems of insufficient combustion of fuel, increased maintenance times, and reduced thermal efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0010] Specific implementation manners: the present application is not limited by the following examples, and specific implementation manners can be determined according to the technical solutions of the present invention and actual conditions.

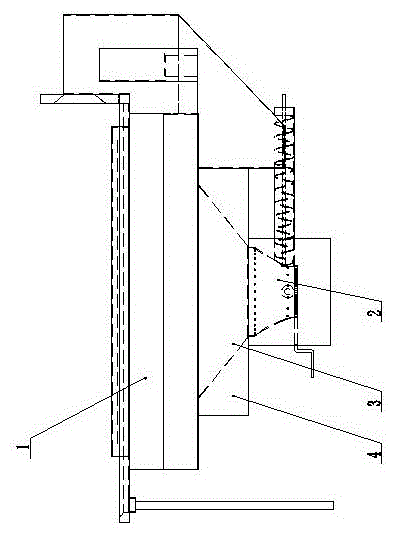

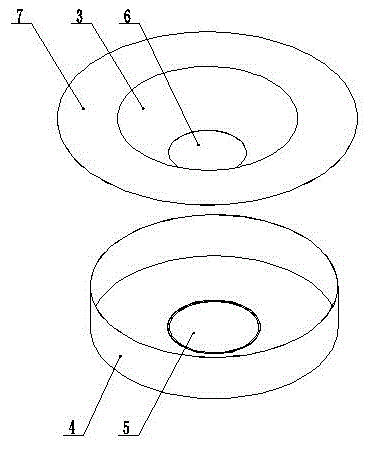

[0011] Example: such as figure 1 , 2 As shown, a water storage type heat dissipation anti-coking structure of a biomass burner includes a water tank 4 arranged between the combustion chamber and the furnace. The upper end of the water tank 4 is open, and the open end is covered with a water tank cover 7. The water tank There is a hole in the center of the bottom surface, and the hole is used to communicate with the combustion chamber, which is the flame port 5. The water tank cover 7 has a hole in the center, and the cavity water tank liner 3 is connected under the hole. The seals are connected so that a water storage space is formed between the water tank liner 3 and the water tank 4 . The water tank liner 3 is in the shape of a tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com