Cooling wall wood mould brick inlaid slot dimension inspection template and use method

A technology for inlaying brick grooves and staves, which is applied in the field of checking the size of the wooden mold inlaying brick grooves in staves. It can solve the problems of difficult control of dimensional tolerances, influence on the quality of inlaid bricks, and large size scalability, so as to achieve the goal of inlaying bricks in wooden molds. The effect of improving the dimensional accuracy of the groove, improving efficiency, and meeting the design requirements of dimensional tolerances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

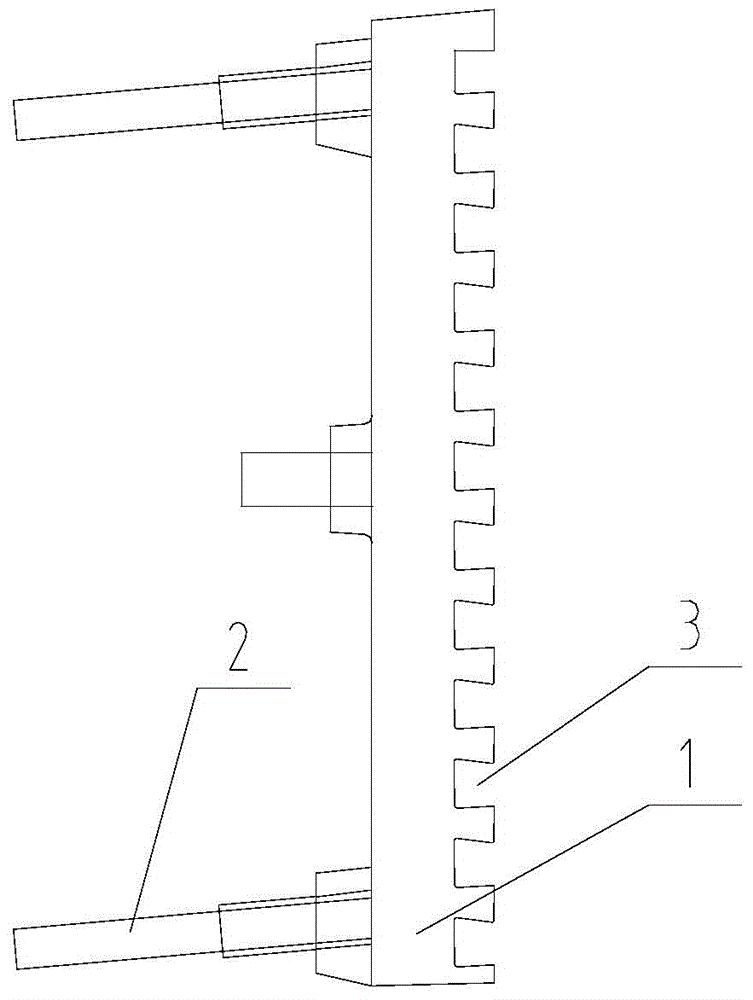

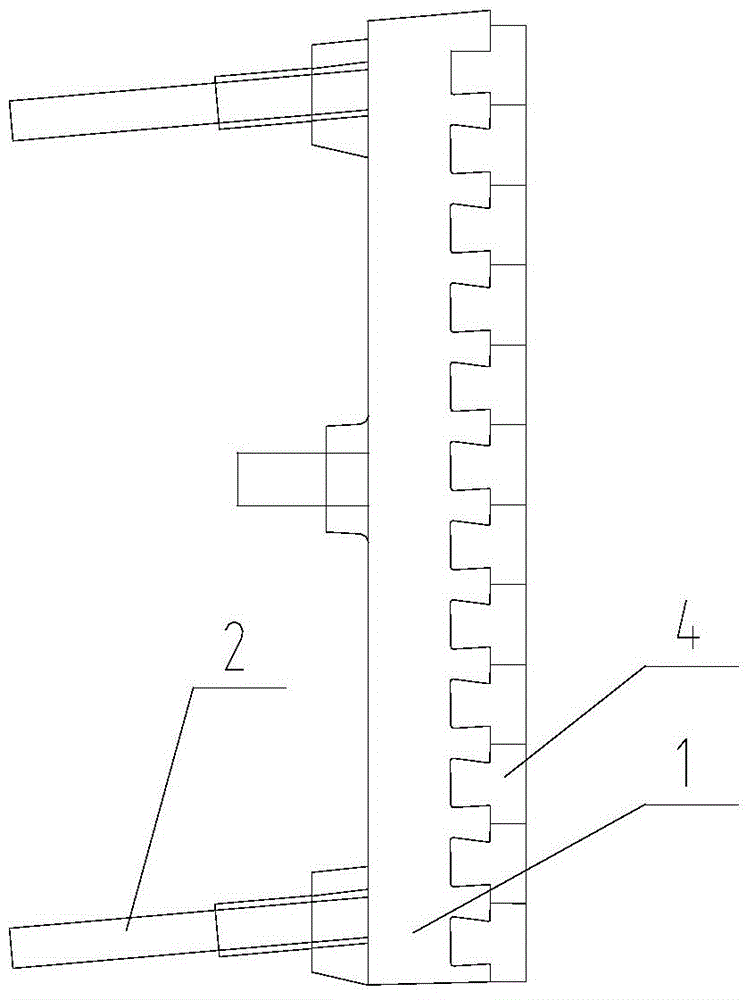

[0059] Sample for checking the size of the stave wooden formwork brick groove:

[0060] 1. To make a duplex model, the material is 3mm thick steel plate, which is processed by CNC machine tools.

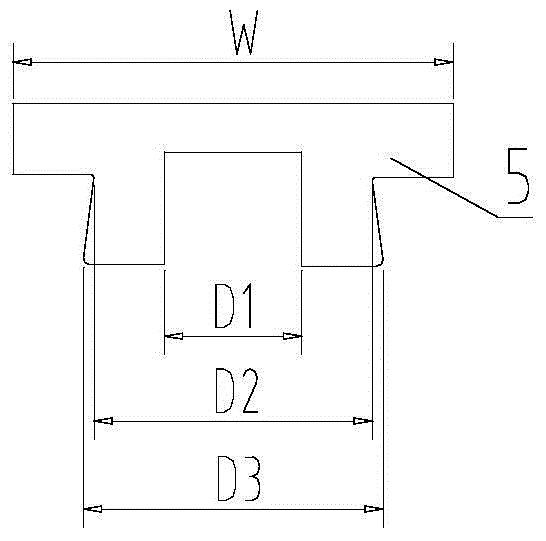

[0061] The double-joint model structure is Π-shaped, the width of the upper part is W, the inner height H1, outer height H2, inner width D1, outer upper width D2, outer lower width D3 of the lower part, where:

[0062] W=2a+20;

[0063] H1=h+20;

[0064] H2=h * (1+ wooden formwork extension chi)+2;

[0065] D1=(a+1)×(1+ wooden formwork extension ruler);

[0066] D2=(a+1+n)×(1+ wooden formwork extension ruler)-0.2;

[0067] D3=(a+1+m)×(1+wooden mold extension ruler)-0.2;

[0068]Among them: m is the width of the upper end of the brick inlaid groove, n is the width of the lower end of the brick inlaid groove, h is the depth of the brick inlaid groove; the wooden mold extension ruler is the pattern magnification rate, or the casting line shrinkage rate; all dimensions are in mm.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com