Flexible electronic detection tool

A flexible and electronic technology, applied in measuring devices, instruments, etc., can solve the problems of high size requirements, waste of resources, complicated design and manufacture of inspection tools and long cycle, and achieve the effect of ensuring repeatability and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

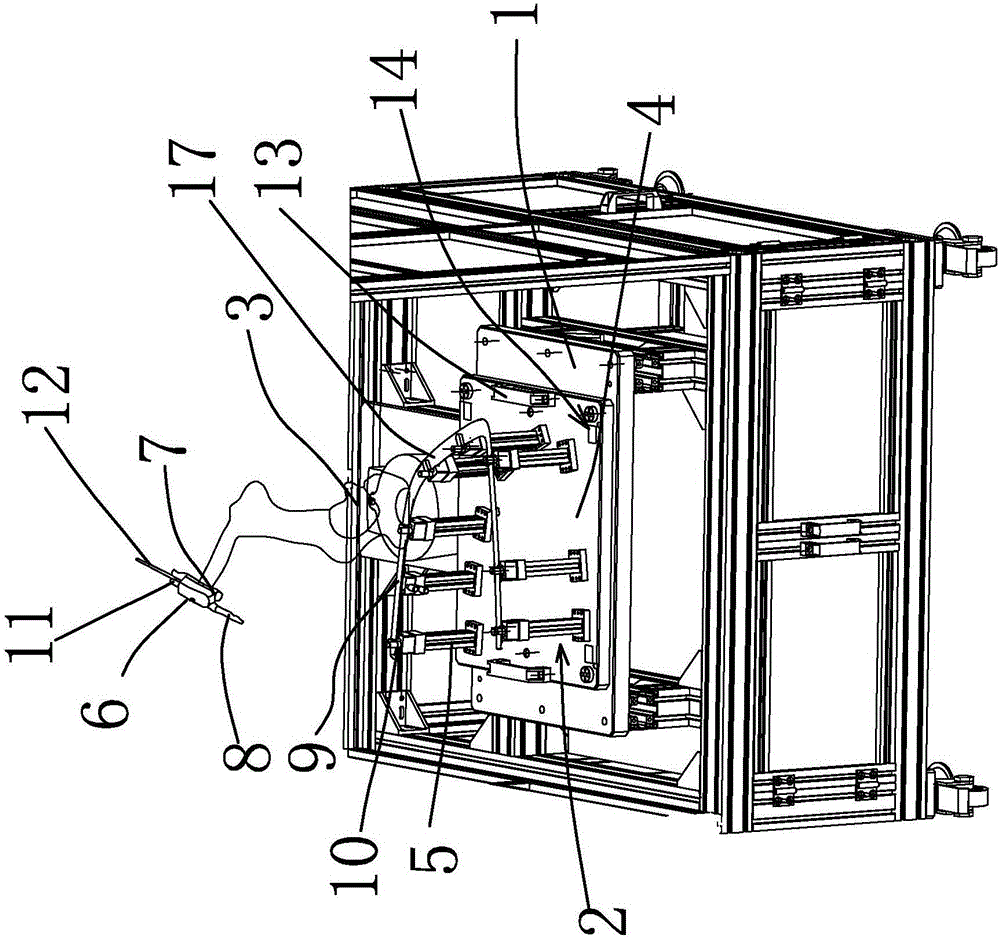

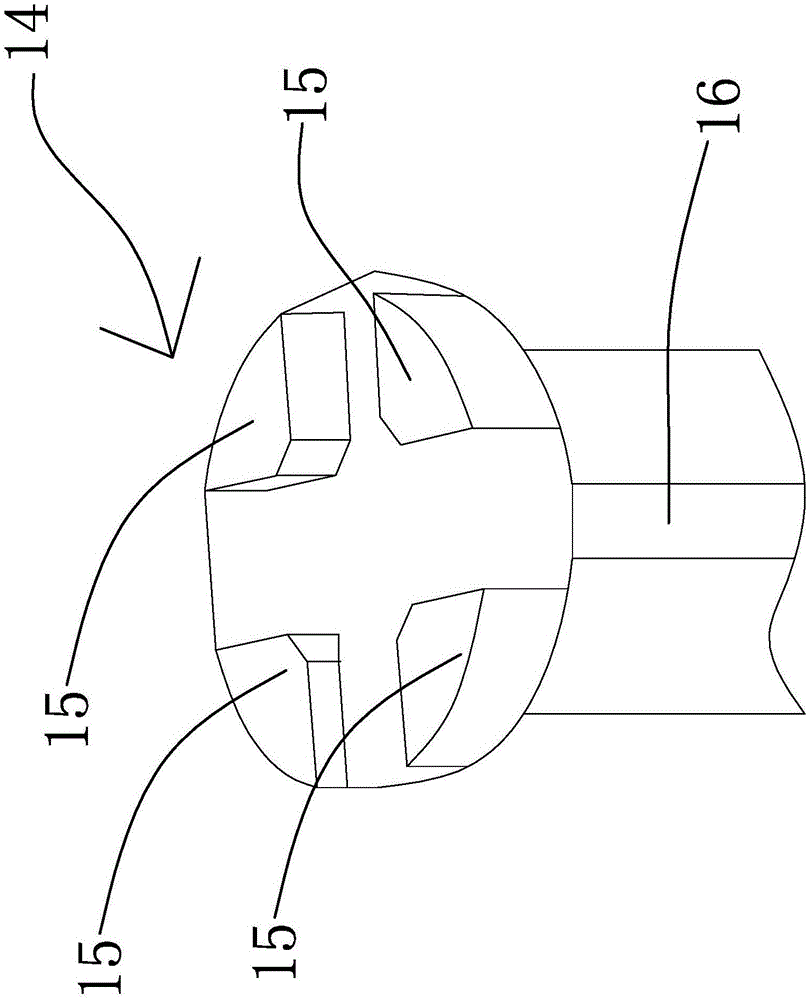

[0019] In the figure, workbench 1; simple fixed fixture component 2; manipulator arm 3; fixture table 4; positioning cylinder 5; sensor component 6; irradiation sensor 7; touch sensor 8; flat measuring point 9; arc measuring point 10 ; clamping piece 11; jack detection rod 12; handle 13; bolt assembly 14;

[0020] Such as figure 1 As shown, the flexible electronic inspection tool mainly includes a workbench 1 and a simple fixed fixture assembly 2 and a manipulator arm 3 arranged on the workbench 1. The simple fixed fixture assembly 2 includes a fixture table 4 and a fixture set on the fixture A plurality of positioning cylinders 5 on the table 4, a sensor assembly 6 is arranged on the head of the manipulator arm 3, the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com