Anisotropic conductive adhesive attaching stage device and anisotropic conductive adhesive attaching method

An anisotropic, conductive adhesive technology, applied in nonlinear optics, instruments, optics, etc., can solve problems such as poor alignment accuracy, long time-consuming, alignment offset, etc., to reduce waste of raw materials, save costs, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

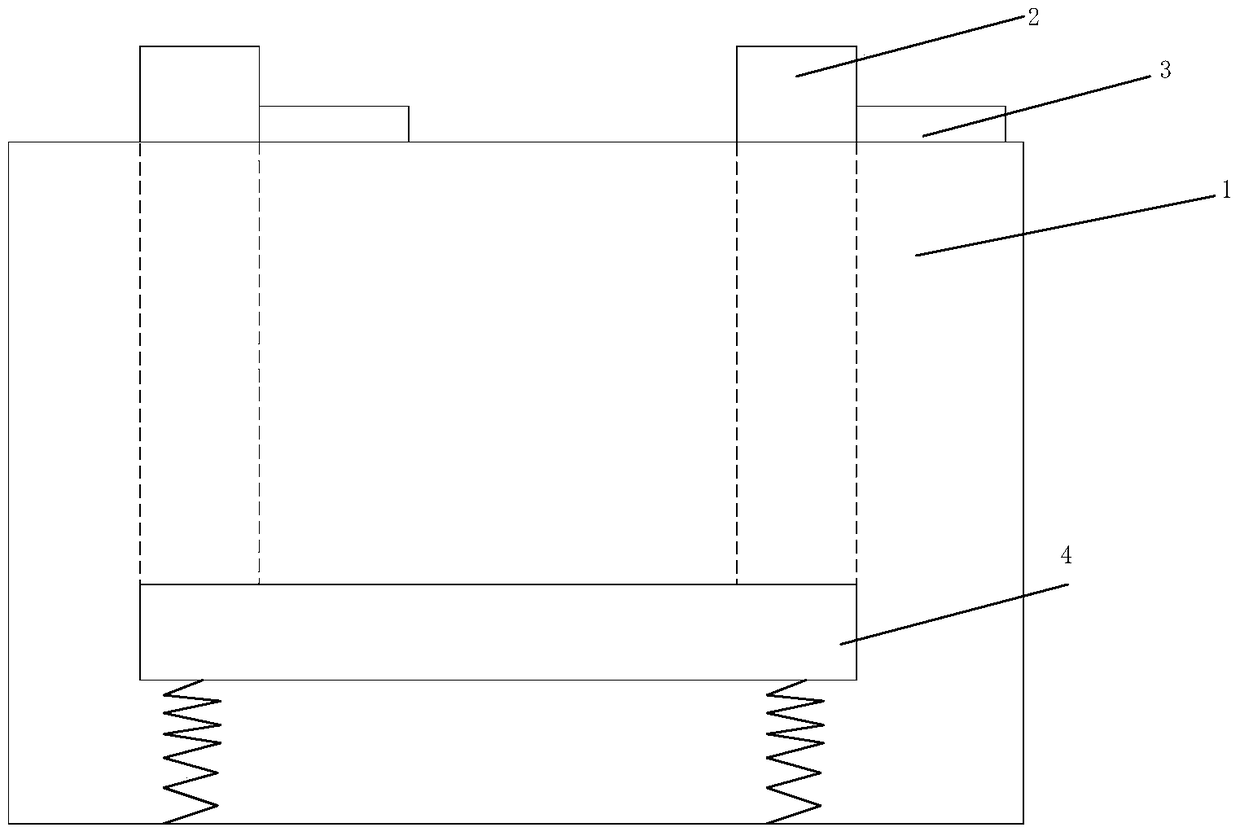

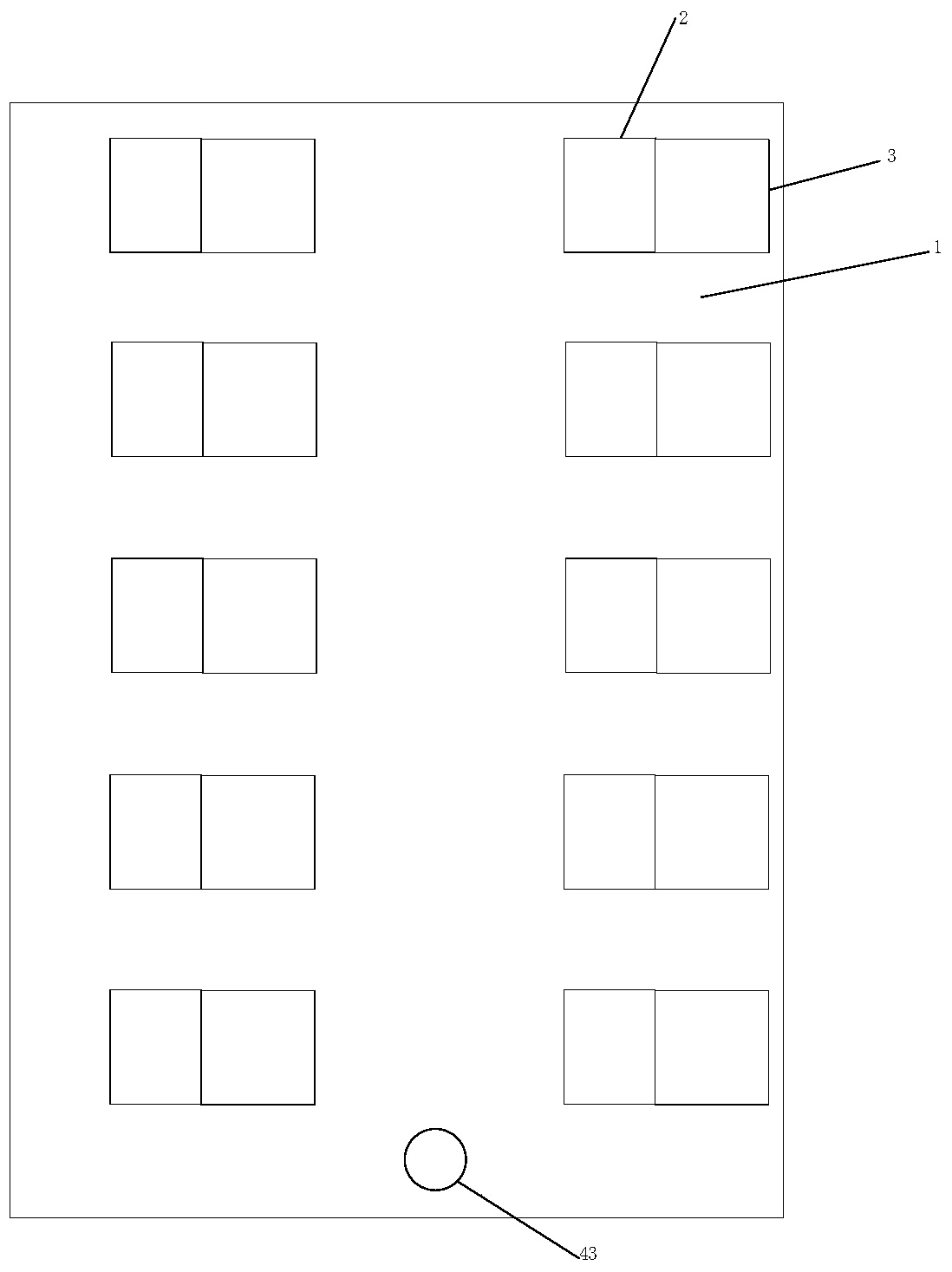

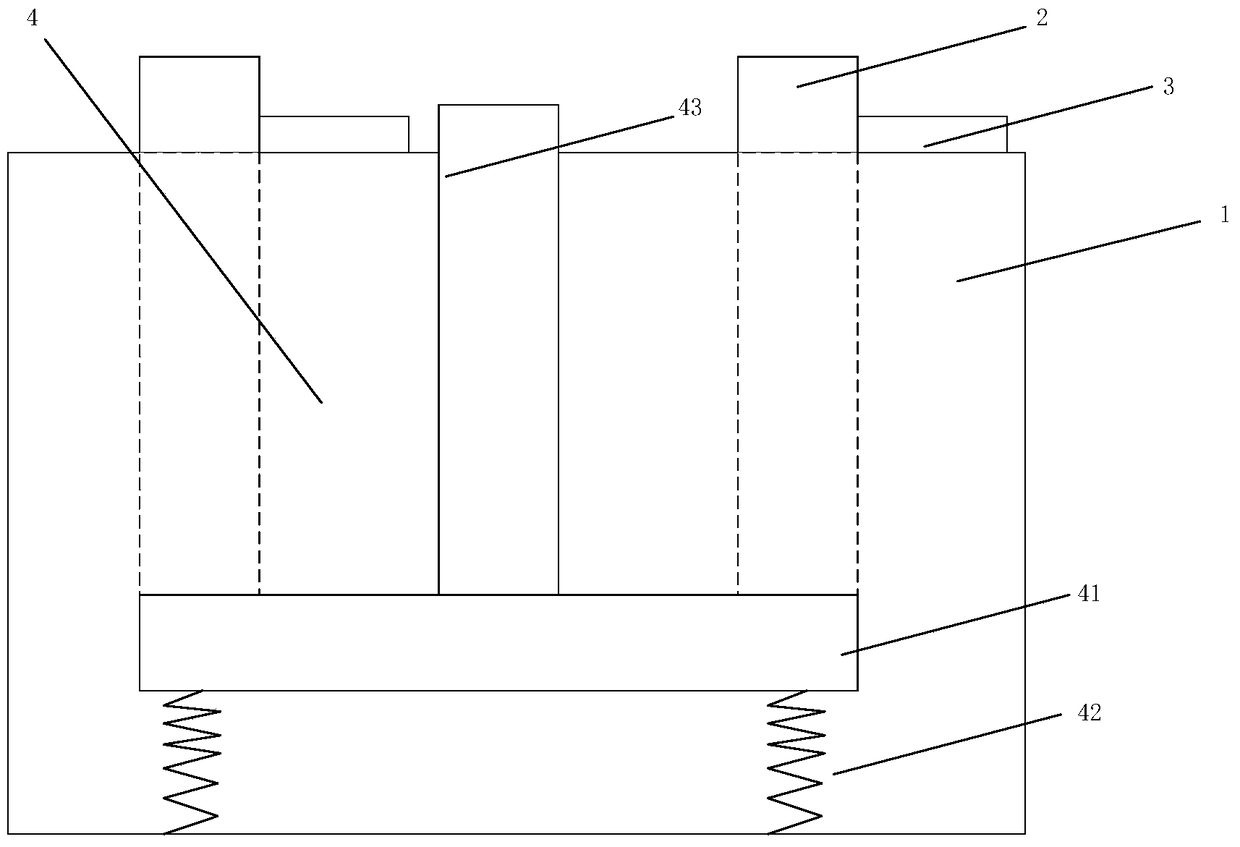

[0035] like Figure 1a-Figure 4 As shown, the present invention provides a device for attaching an anisotropic conductive adhesive to a stage, the device includes: a stage body 1, and the stage body 1 is provided with a plurality of flexible circuit board areas to be placed on the stage body 1 There is a lifting baffle 2 corresponding to at least one area of the flexible circuit board to be placed; the lifting baffle 2 is aligned with the set edge of the area of the flexible circuit board to be placed; the lifting baffle 2 is on the flexible circuit board 3 protruding from the upper surface of the carrier body 1 before the alignment; the lifting baffle 2 retracts from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com