High-pressure casting tapping end plate of dry-type transformer

A dry-type transformer, high-voltage technology, applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., can solve problems such as poor versatility, and achieve the effect of consistent shape and structure, enhanced versatility, neat and beautiful arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below by means of specific embodiments:

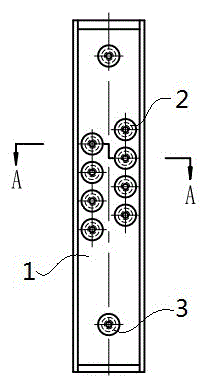

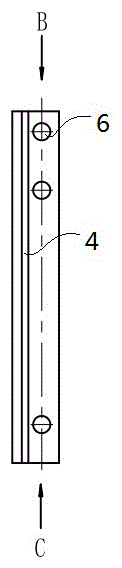

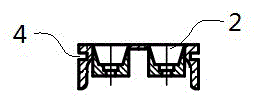

[0024] The reference signs in the drawings of the description include: pouring body body 1 , first pouring hole 2 , second pouring hole 3 , pull groove 4 , stopper 5 , first installation hole 6 , top plate 7 , and second installation hole 8 .

[0025] like figure 1 As shown, the high-voltage casting tap end plate of the dry-type transformer includes a casting body 1 made of channel steel. The bottom surface of the casting body 1 is provided with eight first casting holes 2 and two second casting holes 3. Among them, the eight first pouring holes 2 are divided into two rows, four in each row; two second pouring holes 3 are respectively located at both ends of the pouring body body 1, and the centers of the two second pouring holes 3 are located at the first of the two rows. Bolts for wiring are clamped on the eight first pouring holes 2 and the two second pouring holes 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com