Frame used for combining plurality of motors

A rack and meshing technology, which is applied in the field of racks for combining multiple motors, can solve the problems of easy wear of key moving parts, high motor heat generation, and high power consumption, so as to reduce harmful mechanical wear noise and stabilize the structure Compact and durable, the effect of increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

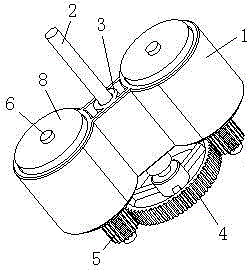

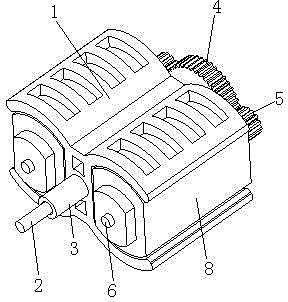

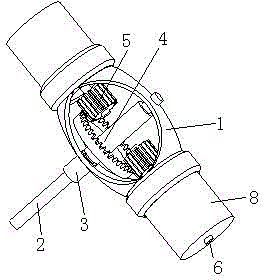

[0035] Such as figure 1 Among them, a frame for combining multiple motors includes a transmission shaft 2, a center wheel 4 fixed on the transmission shaft 2, and a nesting body 1 sleeved on the transmission shaft 2, and the center line of the center wheel 4 is aligned with the transmission shaft. Axis 2 center lines coincide;

[0036] The nesting body 1 includes two fixing grooves 7 and fixing parts connecting the fixing grooves 7. The two fixing grooves 7 are symmetrically arranged with the transmission shaft 2 as the axis of symmetry. The power output shaft 6 of the motor 8 in the groove 7 is provided with a gear 5, and the edge of the center wheel 4 is provided with teeth, and the teeth of the center wheel 4 are meshed with the gear teeth 5 on the power output shaft 6 (or as Image 6 Among them, the power output shaft 6 of the motor 8 placed in the fixed groove 7 is provided with a power split pulley 12, and the power split pulley 12 is connected with the center wheel 4 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com