Compound mixed proportional valve

A mixing ratio and duplex technology, applied in multi-way valves, valve devices, fire rescue, etc., can solve the problems of reduced coverage area, increased fire extinguishing cost, and insufficient mixing of foam agent and fire water, so as to achieve reasonable design, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

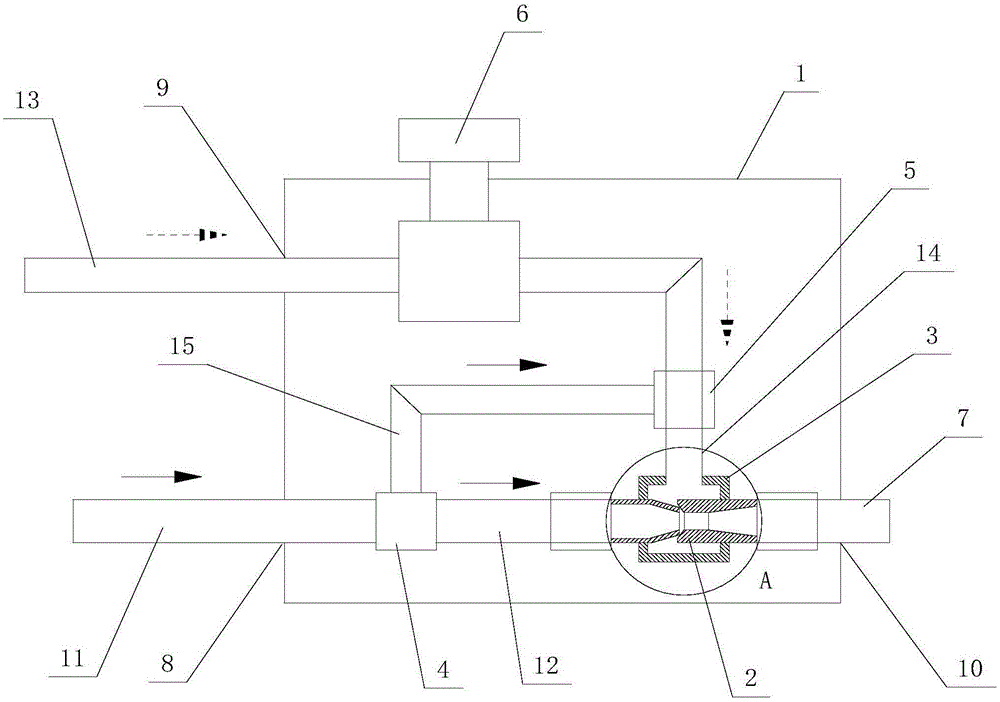

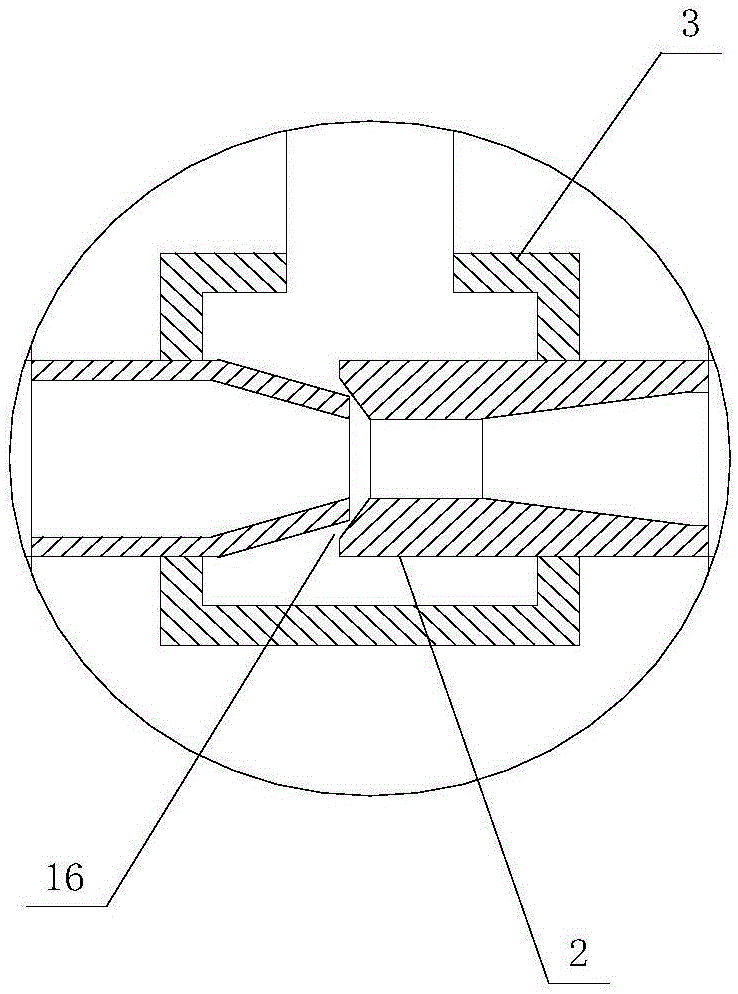

[0017] Such as figure 1 with figure 2 As shown, a compound mixing proportional valve includes a casing 1, a water inlet pipe, a foam agent delivery pipe, a venturi tube 2, a mixing tank 3, a first three-way pipe joint 4, a second three-way pipe joint 5, and a linear flow adjustment The valve 6 and the mixed liquid conveying pipe 7, the mixing box 3 is installed and fixed in the shell 1, the venturi tube 2 horizontally crosses the mixing box 3, the venturi tube 2 is assembled by two parts, and is formed between the two parts On the mating surface 16 in the mixing box 3, the housing 1 is provided with a water inlet pipe installation port 8, a foam agent delivery pipe installation port 9 and a mixed liquid delivery pipe installation port 10, and the water inlet pipe includes a first water inlet pipe 11 and The second water inlet pipe 12, the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com