Dust treatment device

A technology for dust treatment and dust collection devices, which is applied in the directions of combination devices, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of poor effect of frequent maintenance and repair and dust removal, weak continuous operation ability and high manufacturing cost, and achieve continuous The effect of strong operation ability, simple structure and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

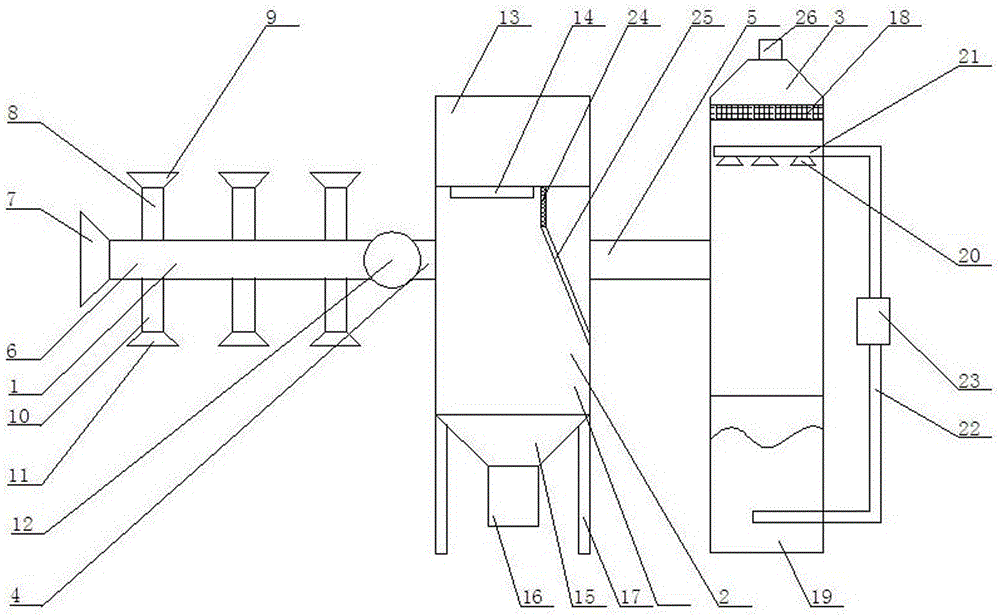

[0017] Such as figure 1 As shown, a dust processing device includes a dust collection device 1, a dust removal box 2, and a spray dust removal tower 3. The dust collection device 1 is connected to the dust removal box 2 through an air inlet pipe 4, and the dust removal box 2 is passed through an air pipe 5 Connect the spray dust removal tower 3, the dust suction device 1 consists of the main dust suction pipe 6, the main dust hood 7, three upper dust suction pipes 8 and the upper dust suction hood 9 and three of the upper dust suction pipe 8 The lower dust suction pipe 10 is composed of a lower dust suction hood 11 and an induced draft fan 12 installed on the lower dust suction pipe 10; the upper end of the dust removal box 2 is equipped with a high-pressure air device 13, and the lower end of the high-pressure air device 13 is provided with an air outlet 14, and the lower end The sedimentation tank 15 is installed, the lower end of the sedimentation tank 15 is equipped with a ...

Embodiment 2

[0019] Such as figure 1 As shown, the right end of the high-pressure wind device 13 is connected to a vertical stainless steel microporous filter plate 24, and the bottom end of the stainless steel microporous filter plate 24 is connected to an inclined stainless steel dust baffle 25. The bottom end of the plate 25 is fixed on the right inner wall of the dust removal box 2.

Embodiment 3

[0021] Such as figure 1 As shown, an exhaust pipe 26 is provided at the top of the spray dust removal tower 3.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap