Steel-structure welding working platform

A working platform and steel structure technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as high working intensity, parts shaking, safety accidents, etc., to reduce the incidence of safety accidents, Easy to use and flexible, improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and embodiment the present invention will be further elaborated, and the direction of the present invention is based on figure 1 prevail.

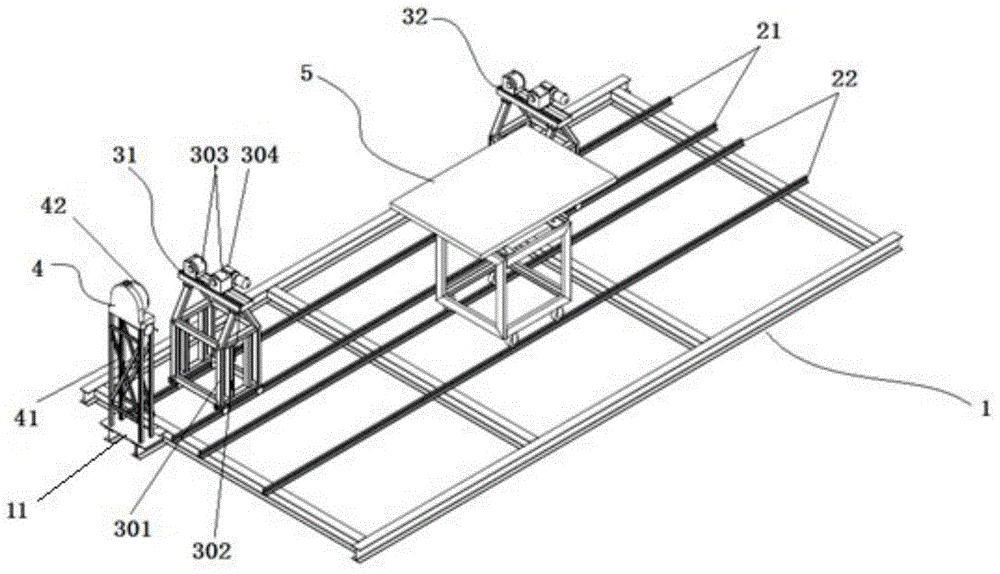

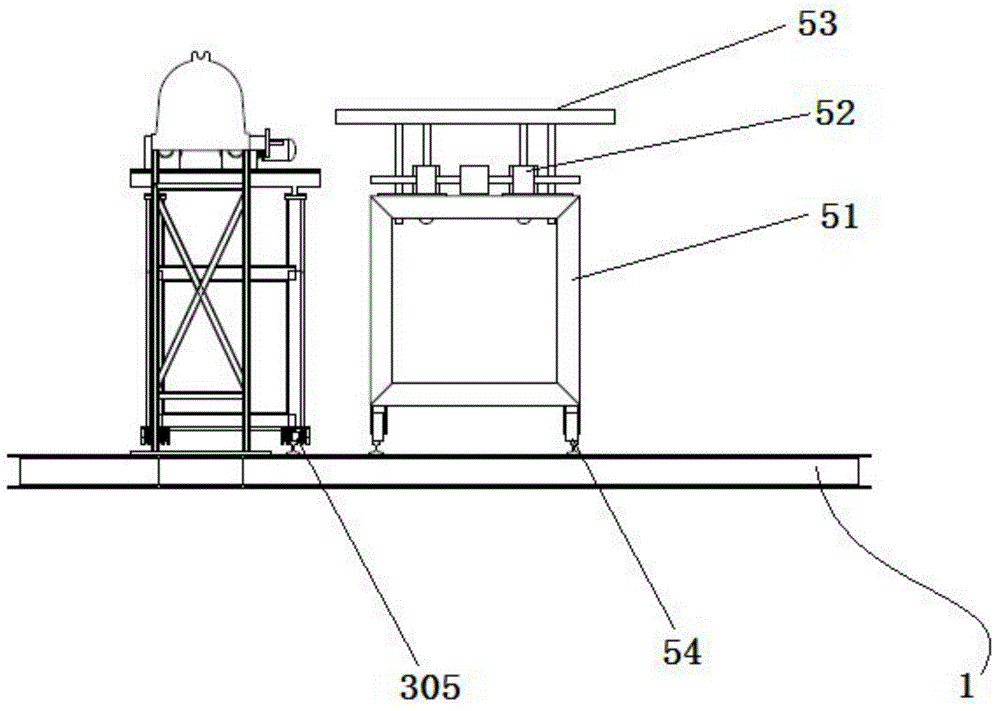

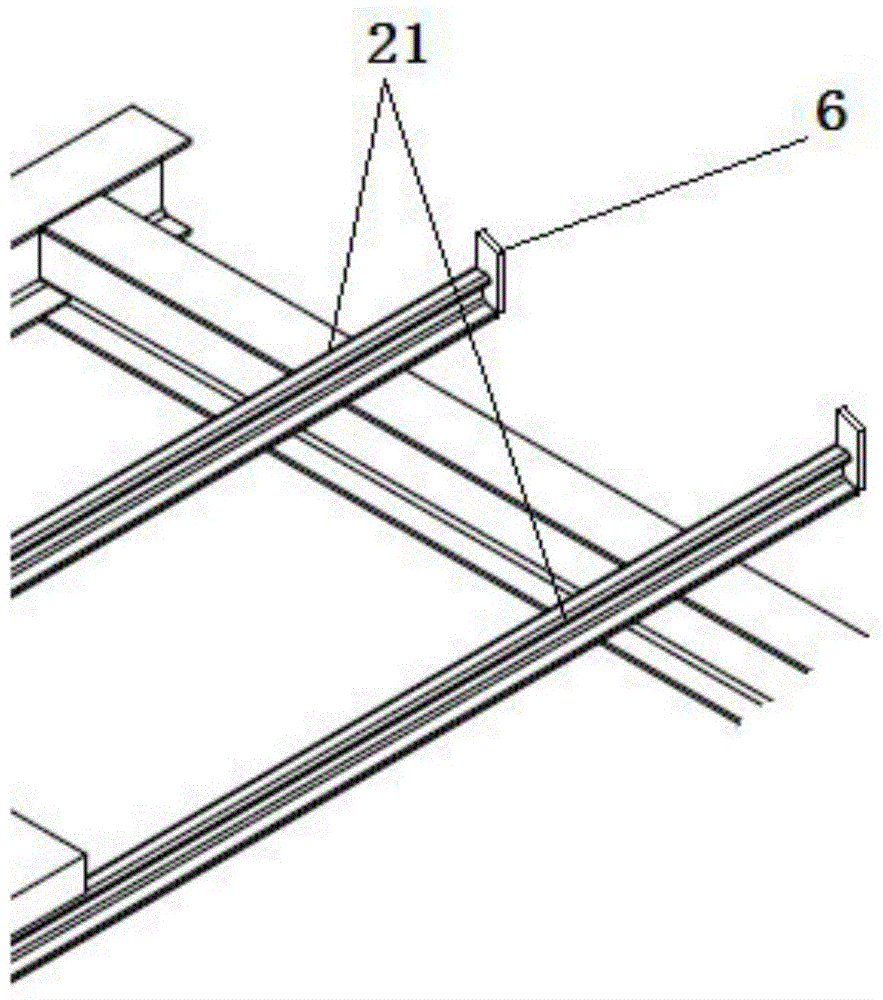

[0024] Such as figure 1 , figure 2 As shown, a steel structure welding work platform includes a platform body 1, a first track 21, a second track 22, two sets of roller devices, a set of vertical dividing head mechanism 4, and a set of liftable workbench 5. The platform body 1 is fixed on the ground, the first rail 21 and the second rail 22 are fixed and welded on the platform body 1 side by side, and the two sets of roller devices are located on the first rail 21, and the two sets of roller devices can move on the first rail 21 , the vertical indexing head mechanism 4 is fixed on the end of the first track 21 , and the liftable workbench 5 is located on the second track 22 .

[0025] Described two cover roller devices are active roller device 31 and passive roller device 32 respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com