Fireworks Automatic Packing Machine

An automatic packaging machine and fireworks technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of high cost, large area, and low efficiency, and achieve the effects of reasonable structure, cost saving, and increased safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

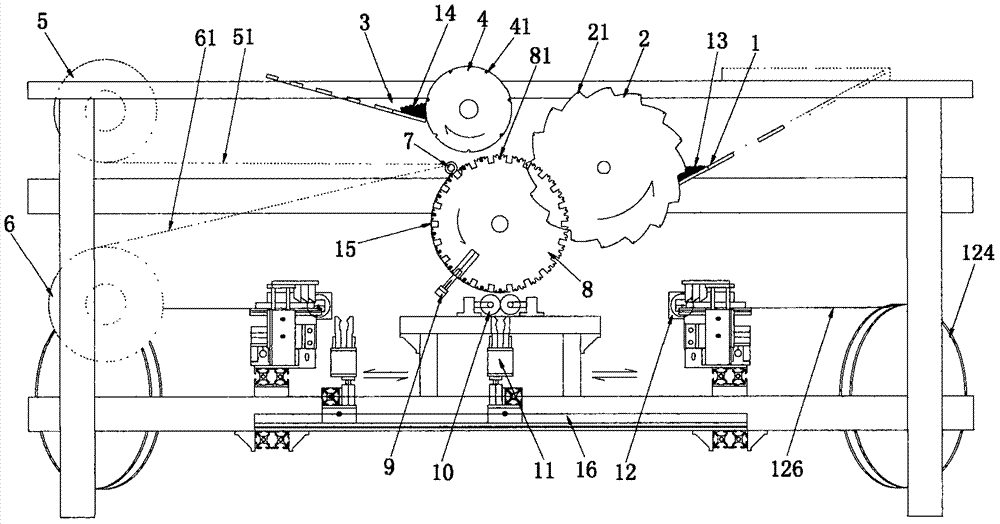

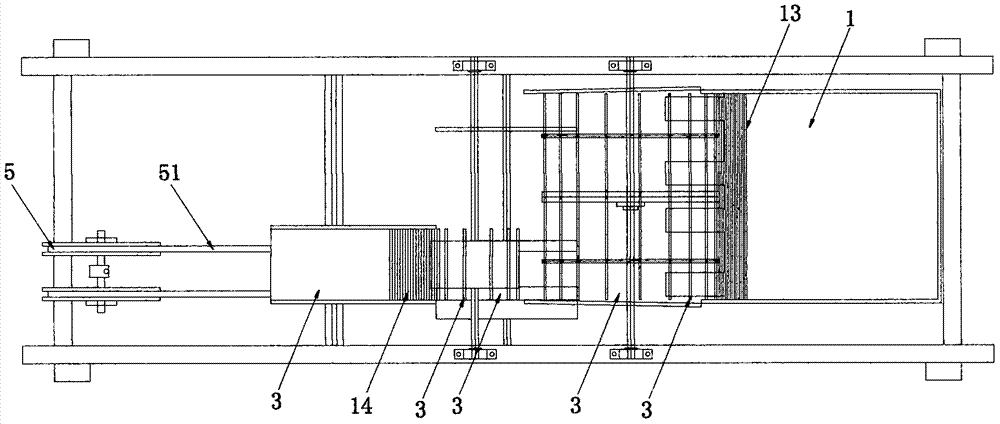

[0018] In order to allow those skilled in the art to understand the present invention more clearly and intuitively, the present invention will be further described below in conjunction with the accompanying drawings.

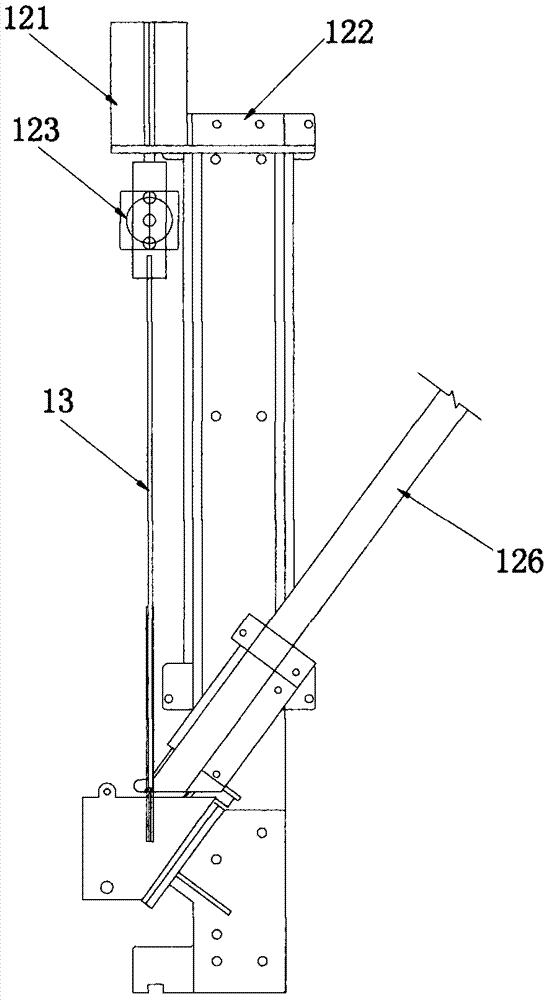

[0019] The firework automatic packing machine of present embodiment is as Figure 1-2 Shown: Including bamboo stick supply box 1 and bamboo stick transmission wheel 2, medicine column supply box 3 and medicine column transmission wheel 4, double-sided tape supply wheel 5, guide paper supply wheel 6, guide wheel 7, assembly transmission wheel 8 , slitting knife 9, binding press wheel 10, transmission clip 11 and winding forming device 12; bamboo stick supply box 1 and medicine column supply box 3 are respectively adjacent to bamboo stick transmission wheel 2 and medicine column transmission wheel 4, and collection transmission wheel 8 is set Below the bamboo stick transmission wheel 2 and the medicine column transmission wheel 4, the bamboo stick transmission whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com