Back shock insulator device for engine

An engine and spacer technology, used in power plants, jet propulsion devices, internal combustion propulsion devices, etc., can solve the problems of insufficient welding connection strength, falling off and separating of the outer tube of the bracket and the welding bracket, affecting the normal use of automobiles, etc., to ensure normal operation. Work, improve the effect of connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The following are preferred embodiments of the present invention, but they do not limit the protection scope of the present invention.

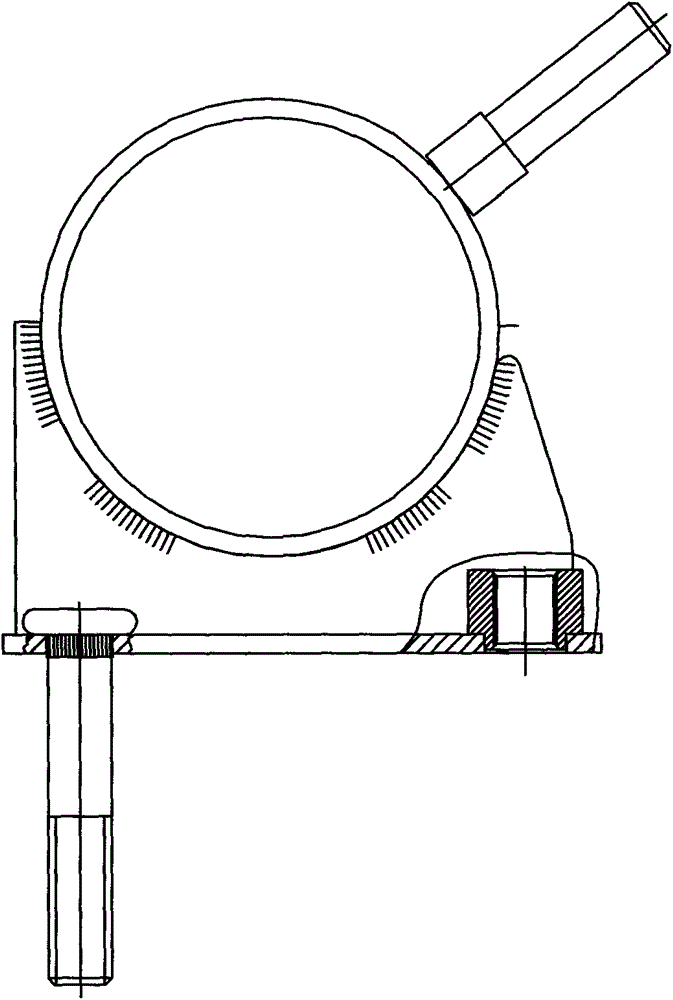

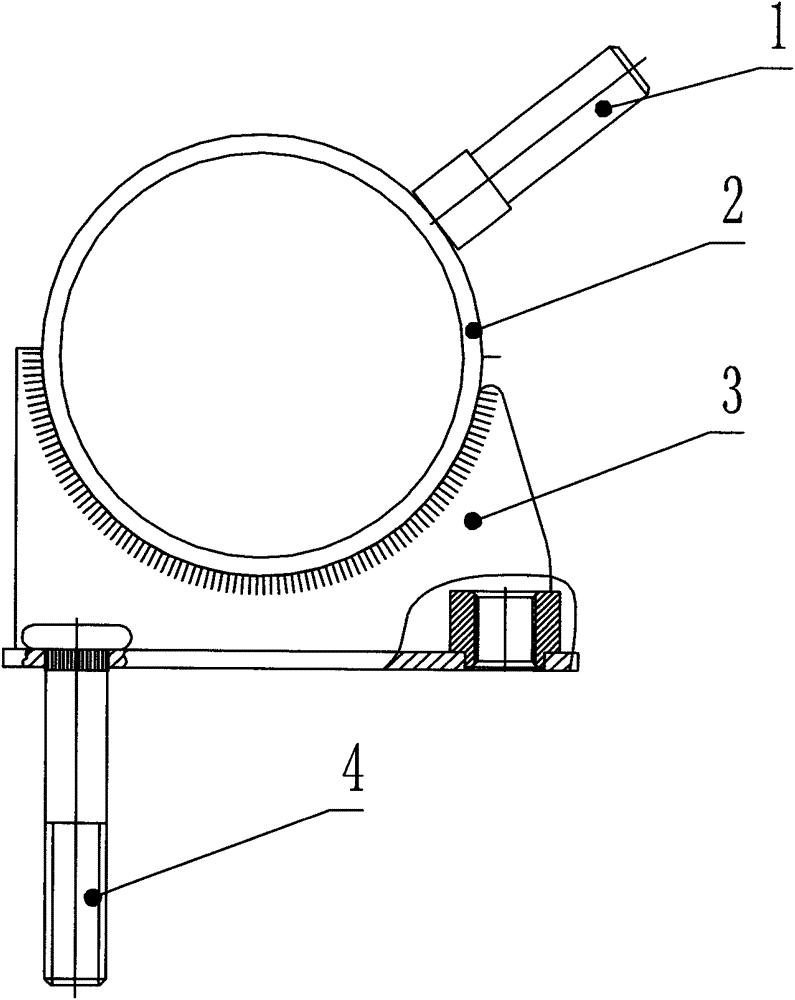

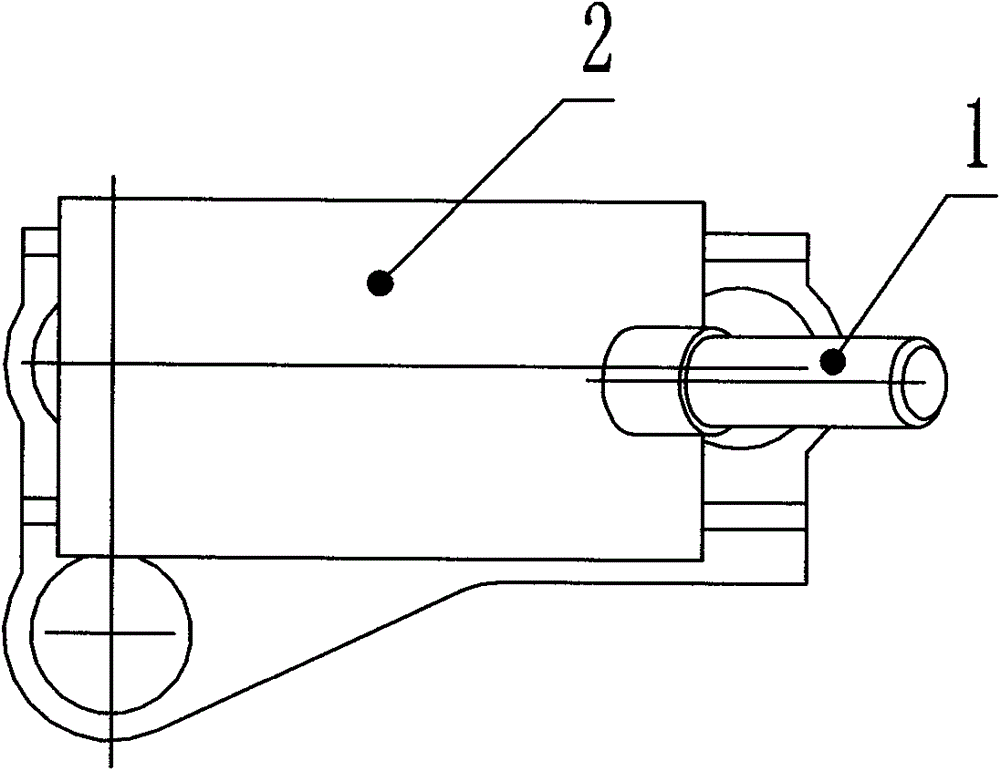

[0014] refer to figure 2 and image 3 As shown, a rear spacer device for an engine of the present invention includes a crash pad assembly 1, a bracket outer tube 2, a welding bracket 3 and connecting bolts 4, and the crash pad assembly 1 is fixed on the bracket outer tube 2, and the connecting bolt 4 is screwed. Connected to the welding bracket 3, the feature is that: the bracket outer tube 2 and the welding bracket 3 are welded in a semicircle.

[0015] The support outer tube 2 among the present invention is actually used in which guide posts, springs and hydraulic equipment are housed for buffering, the same as the prior art.

[0016] The bracket outer tube 2 and the welding bracket 3 are semi-circumferentially welded, which means that the welding bracket 3 is provided with a semi-arc groove, the bracket outer tube 2 is placed in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com