Multifunctional textile cloth and manufacturing method thereof

A textile cloth and multi-functional technology, applied in the field of multi-functional textile cloth and its production, can solve the problems of short service life of projection cloth and curtain cloth, easy falling off of PVC film, affecting projection or shading effect, etc. Low process cost, not easy to fall off, good flatness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described now in conjunction with accompanying drawing.

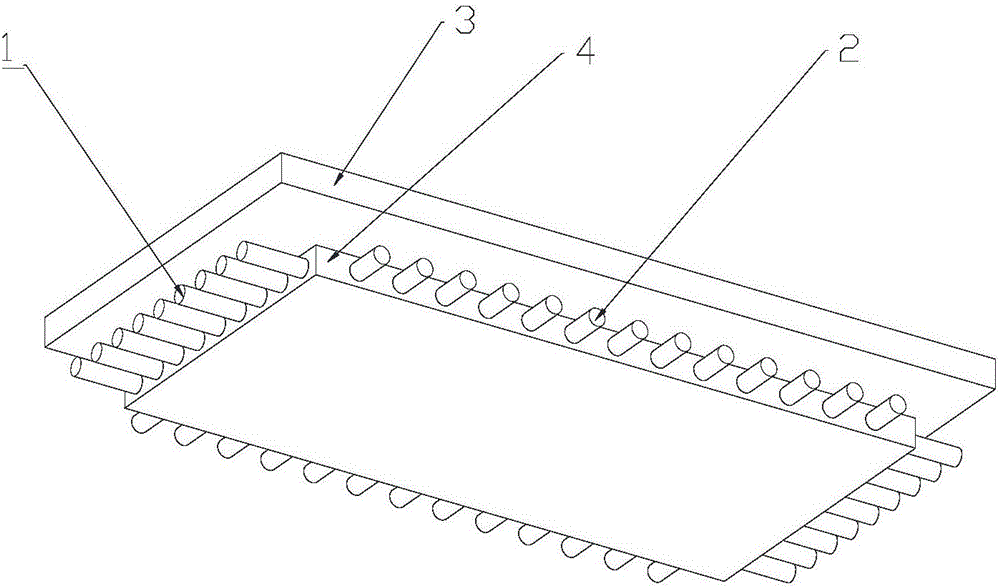

[0014] Such as figure 1 Shown, a kind of multifunctional textile cloth, described multifunctional textile cloth comprises mesh cloth, and the warp thread of described mesh cloth is polyester filament 1, and the weft thread of mesh cloth is nylon monofilament 2, and the surface of described mesh cloth is covered with PVC film 3, the PVC film is bonded on the surface of the mesh cloth by PVC paste resin glue 4.

[0015] The polyester yarn is polyester low elastic yarn.

[0016] A method for making a multifunctional textile cloth, comprising the steps of:

[0017] 1) Weaving the polyester yarn 1 as a warp and the nylon monofilament 2 as a weft into a mesh by a loom;

[0018] 2) Put the mesh cloth into the PVC paste resin glue 4 water, take it out and dry after soaking;

[0019] 3) The PVC film 3 is placed on the dried mesh cloth, and hot-pressed to form a multifunctional tex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com