Board splicing machine

A technology of jigsaw machine and push board, which is applied in the direction of conveyer objects, wooden veneer joints, winding strips, etc., which can solve the problems of low efficiency, large screening error, uneven surface, and achieve labor saving, The effect of high production efficiency and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

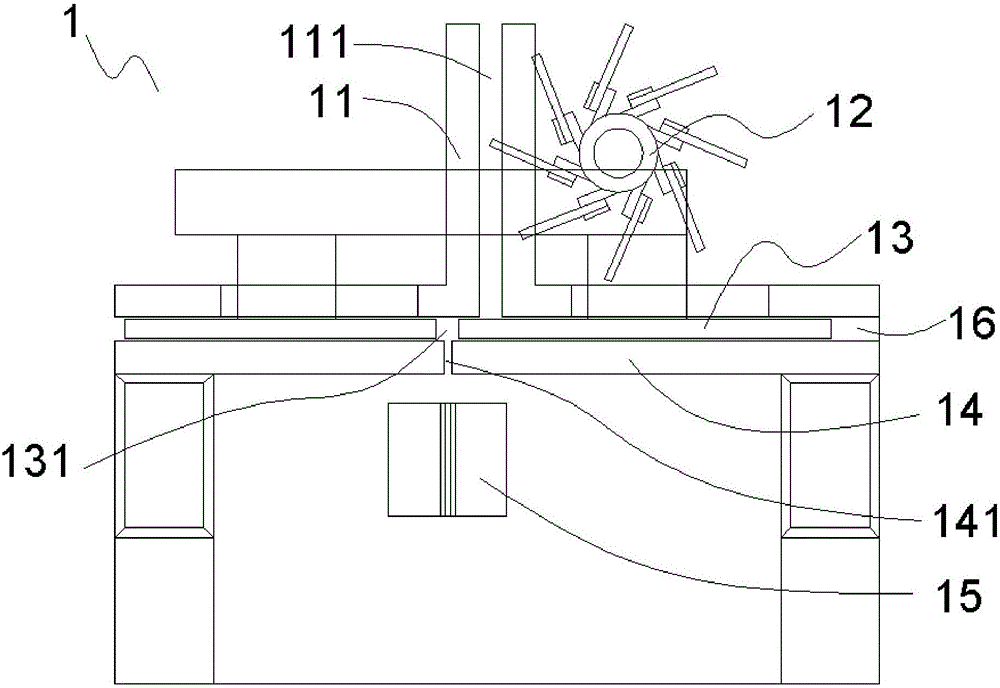

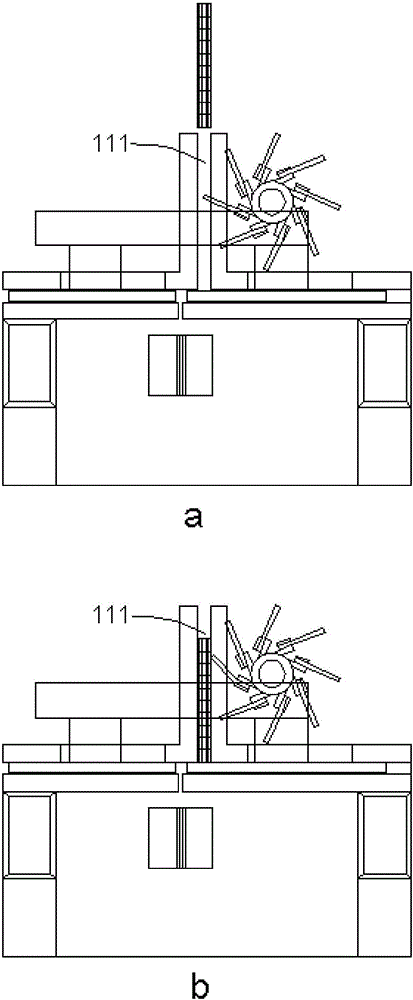

[0043]The jigsaw machine of the present invention includes a feeding device 1 , a strip processing and screening device 2 and an arranging device 3 . Wherein, the feeding device 1 transports the strips to the strip processing and screening device 2, and the strip processing and screening device 2 screens the strips according to the thickness of the strips, and at the same time trims the strips, and then transports the strips to the arrangement device 3. Arrangement device 3 arranges the strips into panels, and finally pushes the strips of the entire panel to the shaping equipment for finalization by the trolley. The strip material O processed by the jigsaw machine of the present invention is a strip-shaped material with a roughly rectangular or square cross section, and is not limited to wood, and can also be other materials for making boards.

[0044] Feeding device

[0045] see figure 1 , which is a schematic structural view of the feeding device of the present invention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com